Active node for changing octahedral truss unit into geometric truss

A technology of variable geometry and octahedron, applied in the field of structural mechanism engineering, can solve the problems of low precision, low stiffness, large joints, etc., and achieve the effect of flexible movement, high precision and small joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

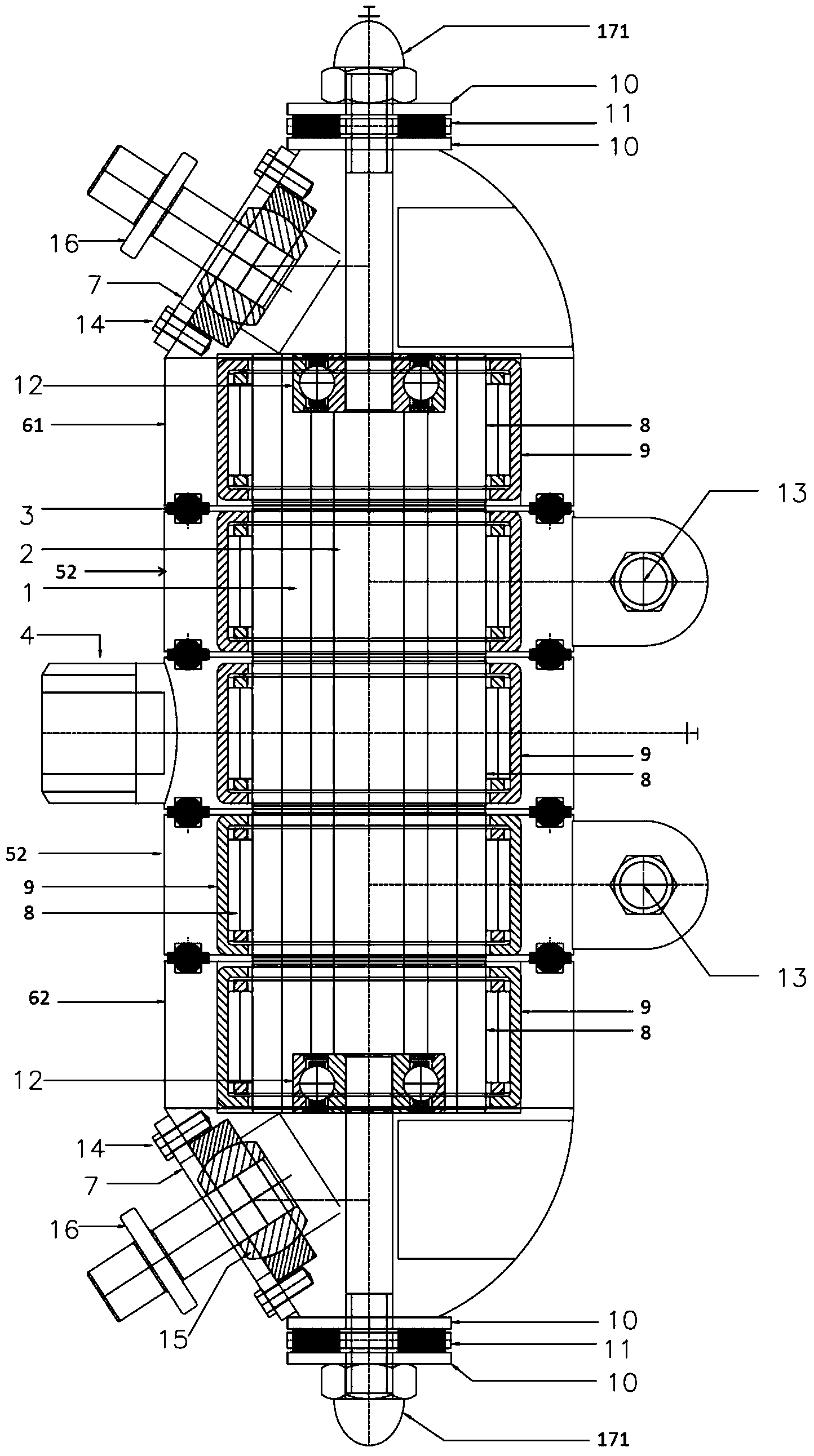

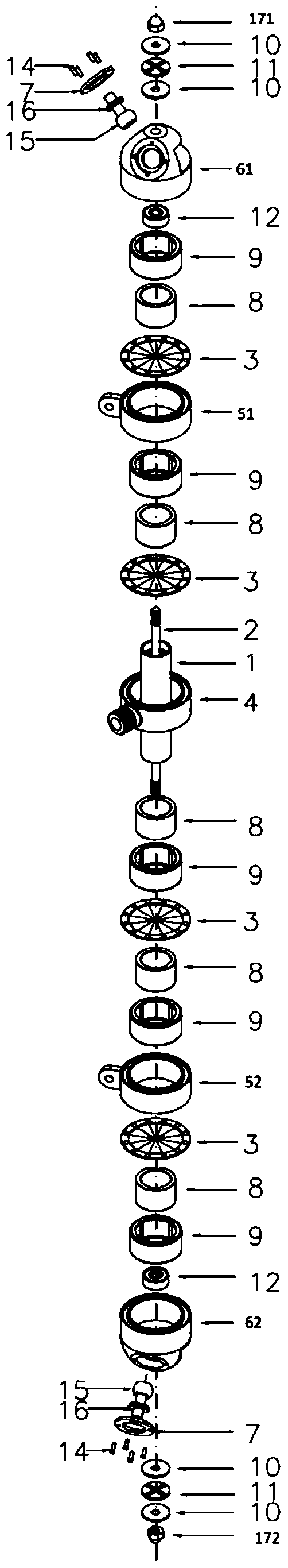

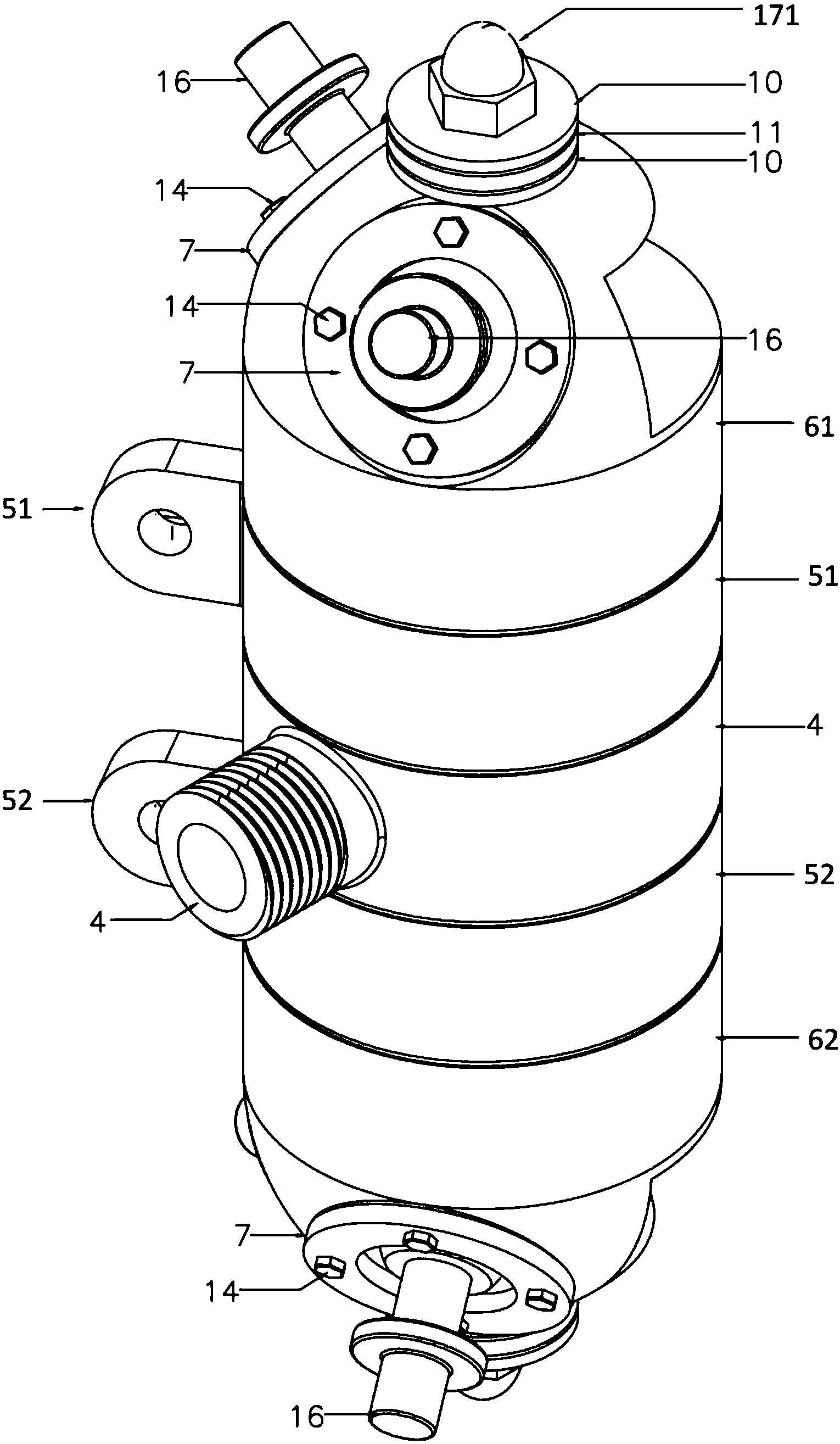

[0038] Such as figure 1 , figure 2 and image 3 As shown, in a preferred embodiment of the present invention, an active node of an octahedral truss unit variable geometry truss includes a node shaft core sleeve 1, a shaft core screw 2, a miniature spherical bearing and a cage 3, and a screw type active rod connection sleeve Ring 4, the first lug type active rod connecting collar 51, the second ear plate type active rod connecting collar 52, the first passive rod hemispherical bearing seat 61, the second passive rod hemispherical bearing seat 62, needle bearing Inner ring 8, needle roller bearing 9, thin thrust needle roller bearing pad 10, thin thrust needle roller bearing and cage 11, deep groove ball bearing 12, first hemispherical nut 171 and second hemispherical nut 172.

[0039] Among them, both ends of the node shaft core sleeve 1 are embedded with deep groove ball bearings 12; five needle roller bearing inner rings 8 are sequentially fitted on the node shaft core sle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com