Air tube heat exchanger

A heat exchanger and air duct technology, which is applied in the field of air conditioning and heat exchange devices, can solve the problems of small diameter of the sealed pipe of the fin heat exchanger, narrow gap between fins and increased installation and construction difficulty, etc. Achieve the effect of increasing heat exchange area and time, high heat exchange rate and reducing power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

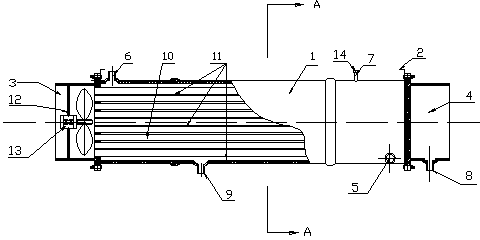

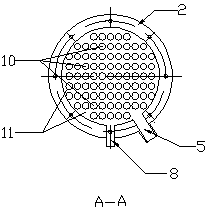

[0015] From Figure 1-2 It can be seen from the figure that an air duct heat exchanger includes a shell 1 and a mounting bracket 2 provided on the shell 1, and is characterized in that: the shell 1 is in the shape of a barrel, and the two ends of the shell 1 are open , one end of the housing 1 is an air inlet 3, the other end of the housing 1 is an air outlet 4, and the housing 1 is provided with a liquid inlet 5, a liquid outlet 6, an exhaust port 7, a drain port 8 and a sewage outlet 9. There are several round tubes 10 inside the shell 1, the two ends of the round tubes 10 are open, and the closed liquid cavity 11 is between the two ends of the round tubes 10, and the air inlet 3 of the shell 1 is provided with a filter 12 and fan 13. The liquid inlet 5 and the liquid outlet 6 are connected with the host through pipelines. Valves 14 are provided on the exhaust port 7 and the sewage discharge port 8 . The drain port 8 is connected to the drain pipe. The fan 13 power suppl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com