Detection fixture for tensile testing of steel wires

A tensile test and detection fixture technology, applied in measuring devices, instruments, scientific instruments, etc., can solve the problems of bead wire fixture slippage and detection data inaccuracy, and achieve the effect of avoiding slippage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

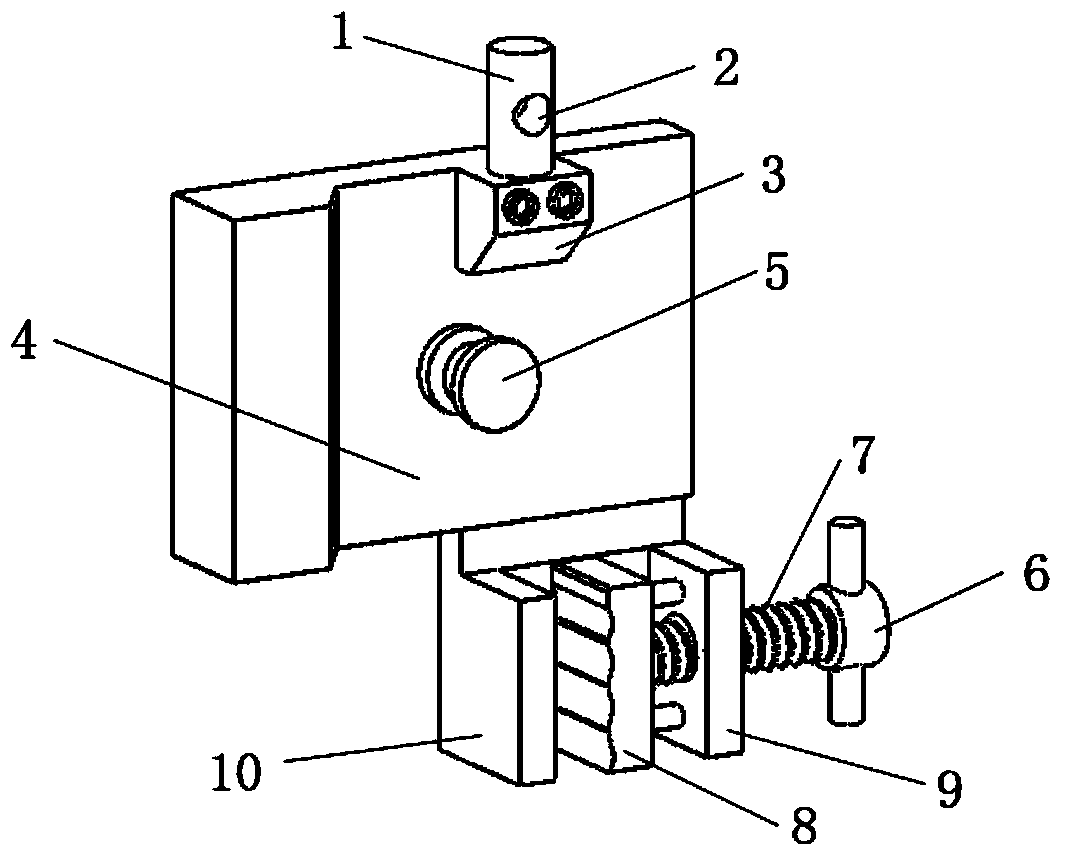

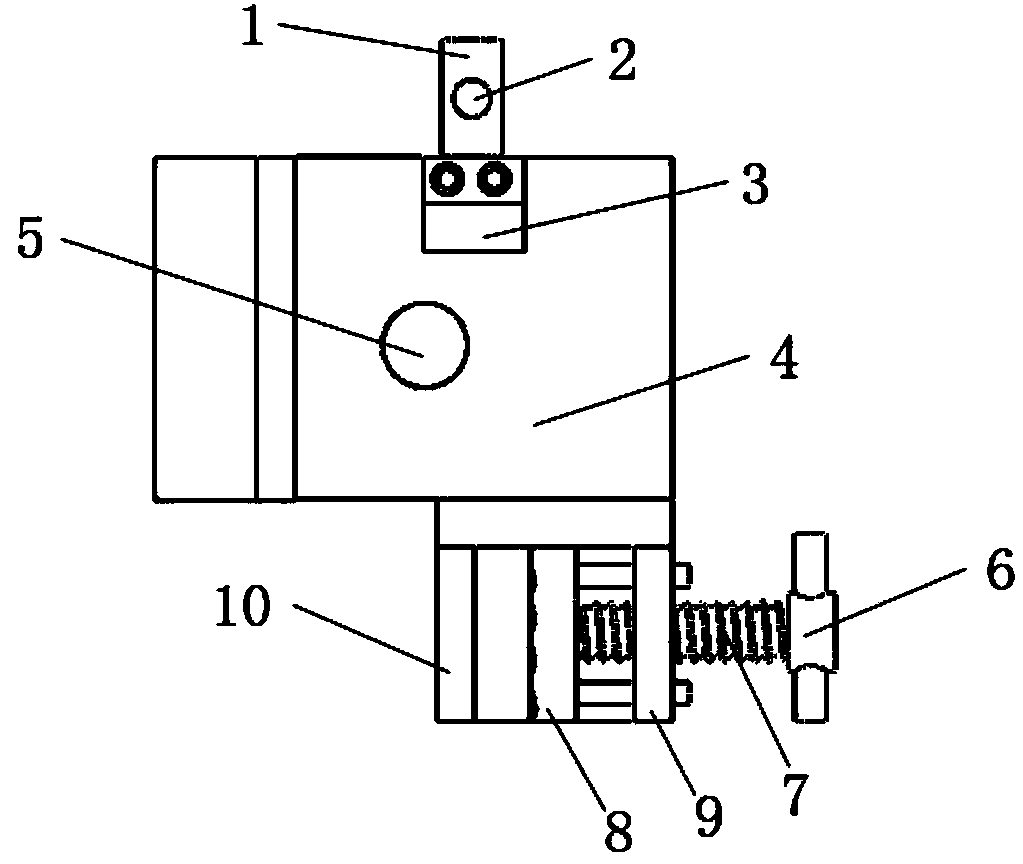

[0013] The technical solutions of the present invention will be further specifically described below through embodiments and in conjunction with the accompanying drawings.

[0014] ginseng figure 1 As shown, the tensile test detection fixture includes a main body 4, the lower end of the main body 4 is fixed with a fixed block 10 and a limit block 9, an action space is formed between the fixed block 10 and the limit block 9, wherein the limit block 9 There are screw holes.

[0015] A chuck 8 is provided in the actuating space, and the side of the chuck 8 facing the fixed block 10 is a clamping surface. The clamping surface is set in a corrugated (teeth-like) shape, and the material of the chuck 8 is preferably 06Cr19Ni10 stainless steel , which can prevent the bead wire from slipping on the chuck during the tensile test.

[0016] A threaded rod 7 is rotatably provided in the screw hole of the limit block 9, one end of the threaded rod 7 is fixed to the chuck 8, and the other ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com