Optical fiber adaptation terminal

A technology of transfer terminal and connection terminal, which is applied in the direction of fiber mechanical structure, etc., can solve the problems of limited operating environment conditions, unfavorable safe operation of substations, and large volume of optical fiber junction boxes, so as to improve engineering quality and fault handling speed and convenience. Test and Troubleshoot, Connectivity Information Intuitive Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

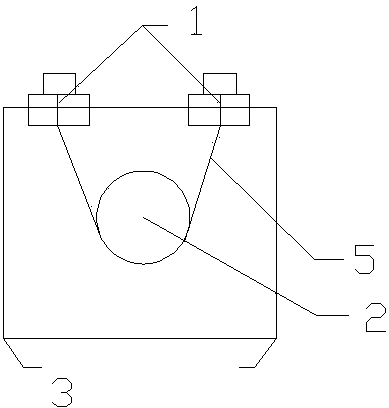

[0024] Embodiment 1: as figure 1 The two optical fiber flanges are arranged on one end surface of the packaging box.

[0025] The two optical fiber flanges are respectively arranged on both sides of the packaging box, specifically designed according to the shape of the packaging box:

Embodiment 2

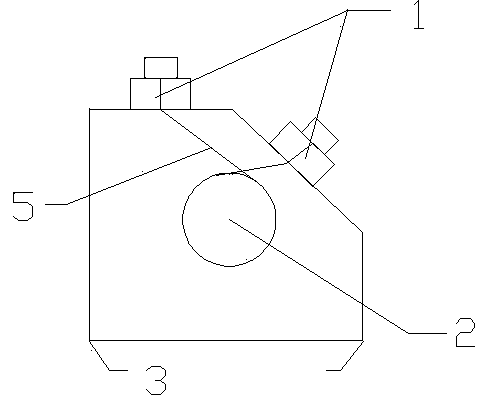

[0026] Embodiment 2: as figure 2 The vertical section of the packaging box is pentagonal, and the two optical fiber flanges are respectively arranged on two adjacent side surfaces of the packaging box.

Embodiment 3

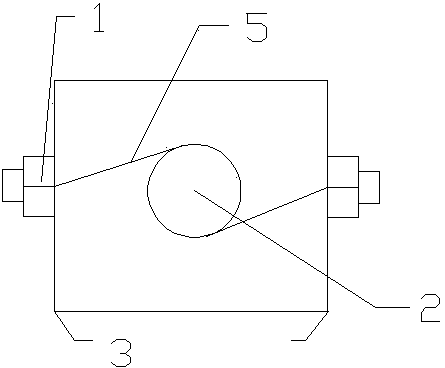

[0027] Embodiment 3: as image 3 The two optical fiber flanges are respectively arranged on two opposite sides of the packaging box.

[0028] The present invention is mainly installed in the intelligent substation protection screen 6 and the intelligent terminal box 4. The specifications of the optical fiber flanges are configured according to the common flange types FC, SC, and ST. Other types can also be flexibly configured according to engineering needs. The three types of flanges Optical fiber transfer terminals can be flexibly installed according to project configuration requirements, among which ST type is mainly used for horizontal installation mode such as Figure 4 As shown, FC and SC types can be flexibly installed vertically according to the internal space of the screen cabinet and the fixing method of optical cables, such as Figure 5 shown.

[0029] The present invention replaces the traditional ODF optical fiber fusion splicing unit with an optical fiber transf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com