Method for acquiring frequency response function of numerically-controlled machine tool based on cutting excitation

A technology of frequency response function and numerical control machine tool, applied in the direction of digital control, electrical program control, etc., can solve the problem that the frequency response function of the machine tool structure cannot be obtained directly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In this embodiment, the method of the present invention is preferably described by taking the XHK5140 vertical machining center as an example.

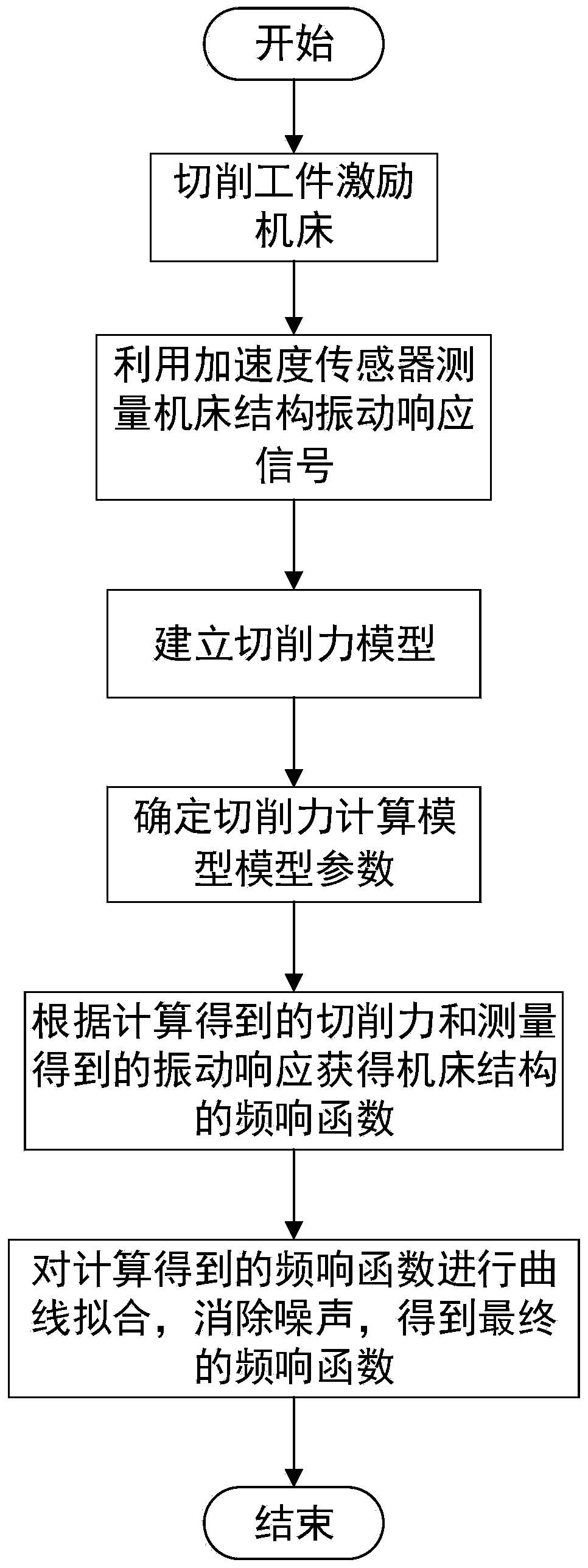

[0024] The method for synthesizing the frequency response function of the CNC machine tool under the working state of the present embodiment includes the following steps, wherein figure 1 Reflected the flow chart of frequency response function of the present invention:

[0025] (1) Obtain the vibration response output signal of the CNC machine tool in the cutting process

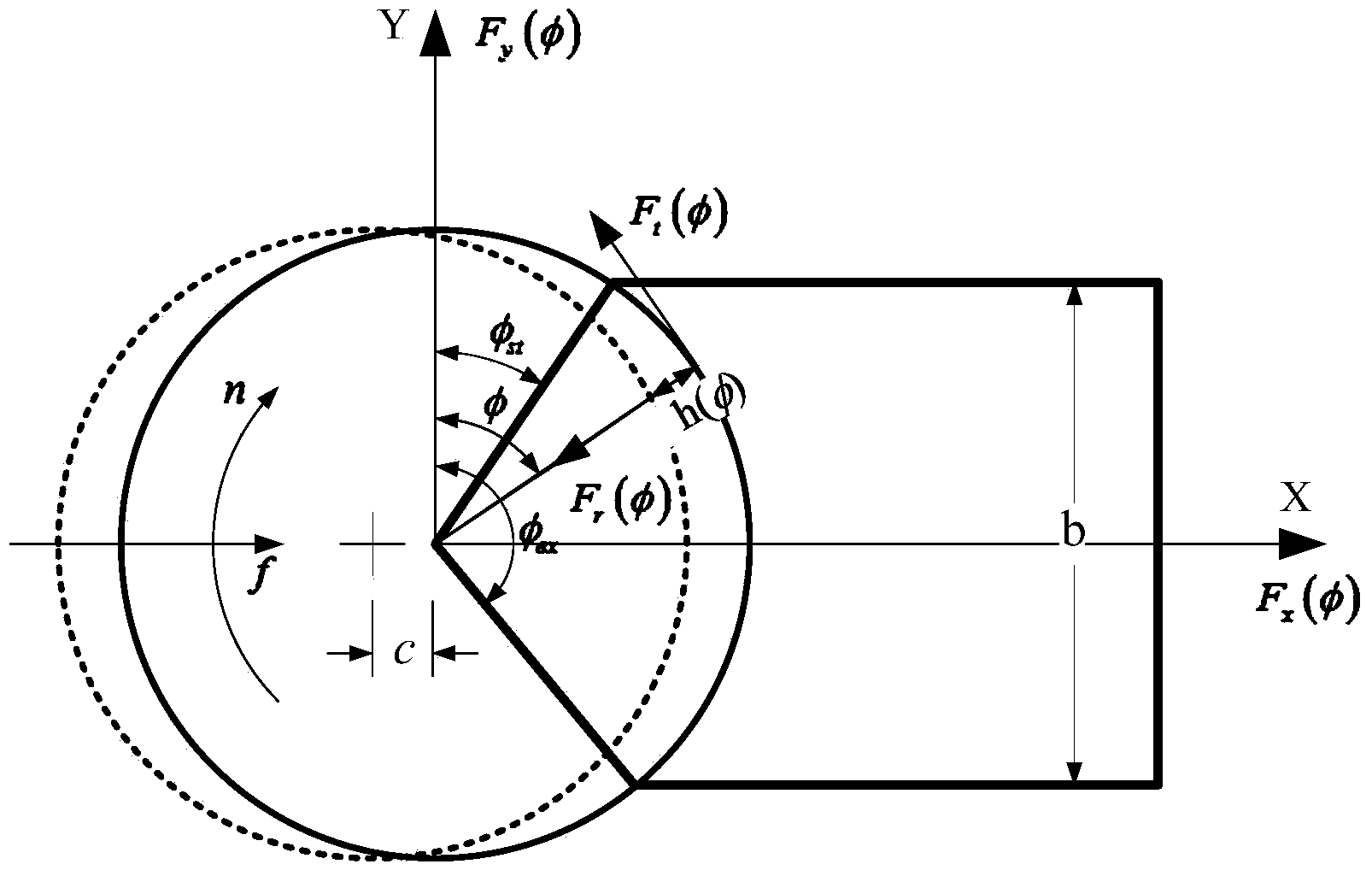

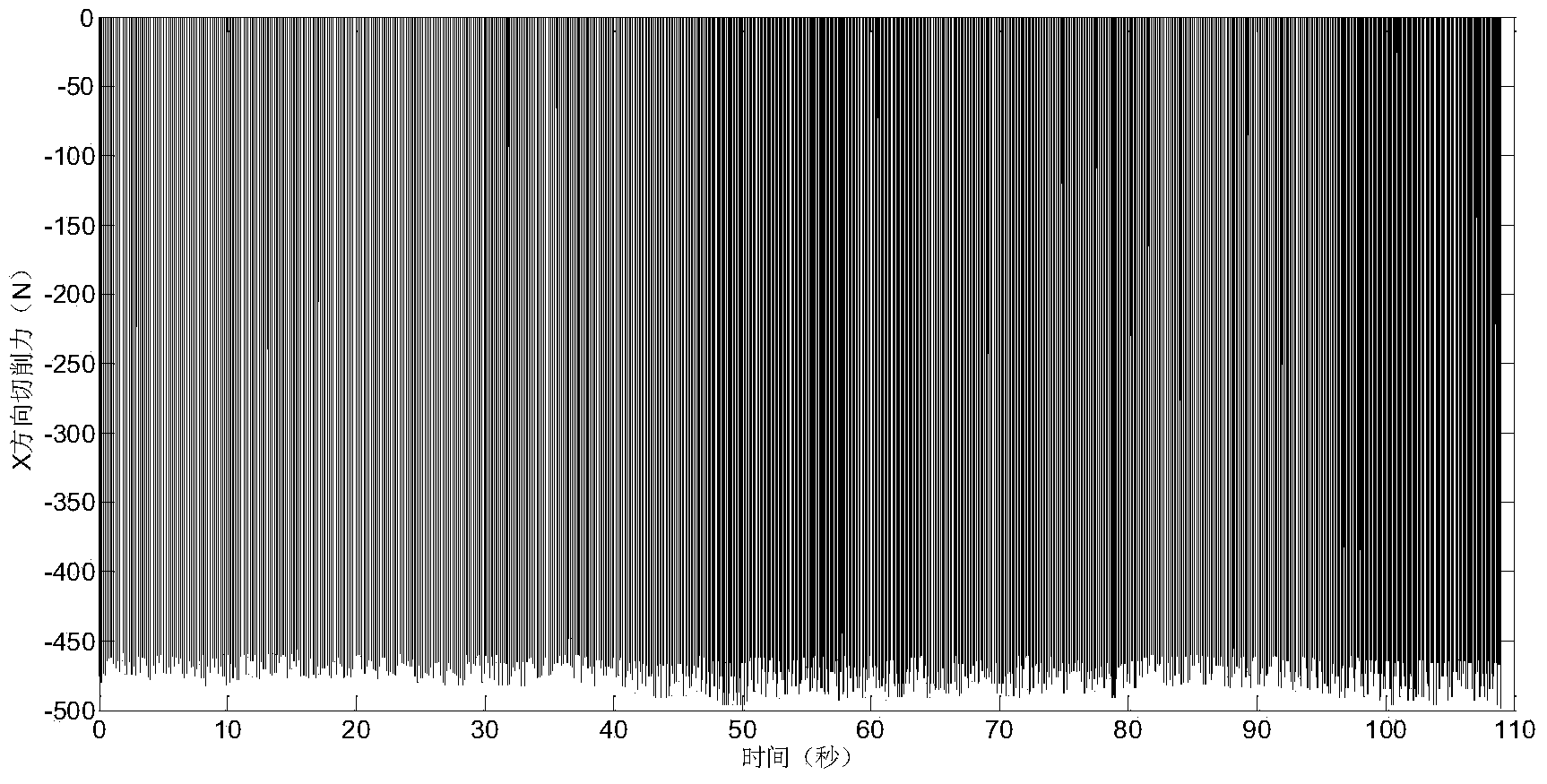

[0026] Choose an appropriate cutting excitation scheme, such as controlling the spindle to rotate randomly to cut workpieces, cutting workpieces with random shapes, etc., and excite the machine tool through the generated cutting force. In this embodiment, the machine tool is excited by controlling the main shaft to randomly rotate and cut the narrow boss workpiece; the acceleration sensor is used to measure the vibration response signal x(t) of key parts suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com