Method for determining fatigue crack safe damage growth period of airplane structure

A technology for fatigue crack growth and fatigue cracks, which is applied in the field of determining the safe damage growth period of fatigue cracks in aircraft structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

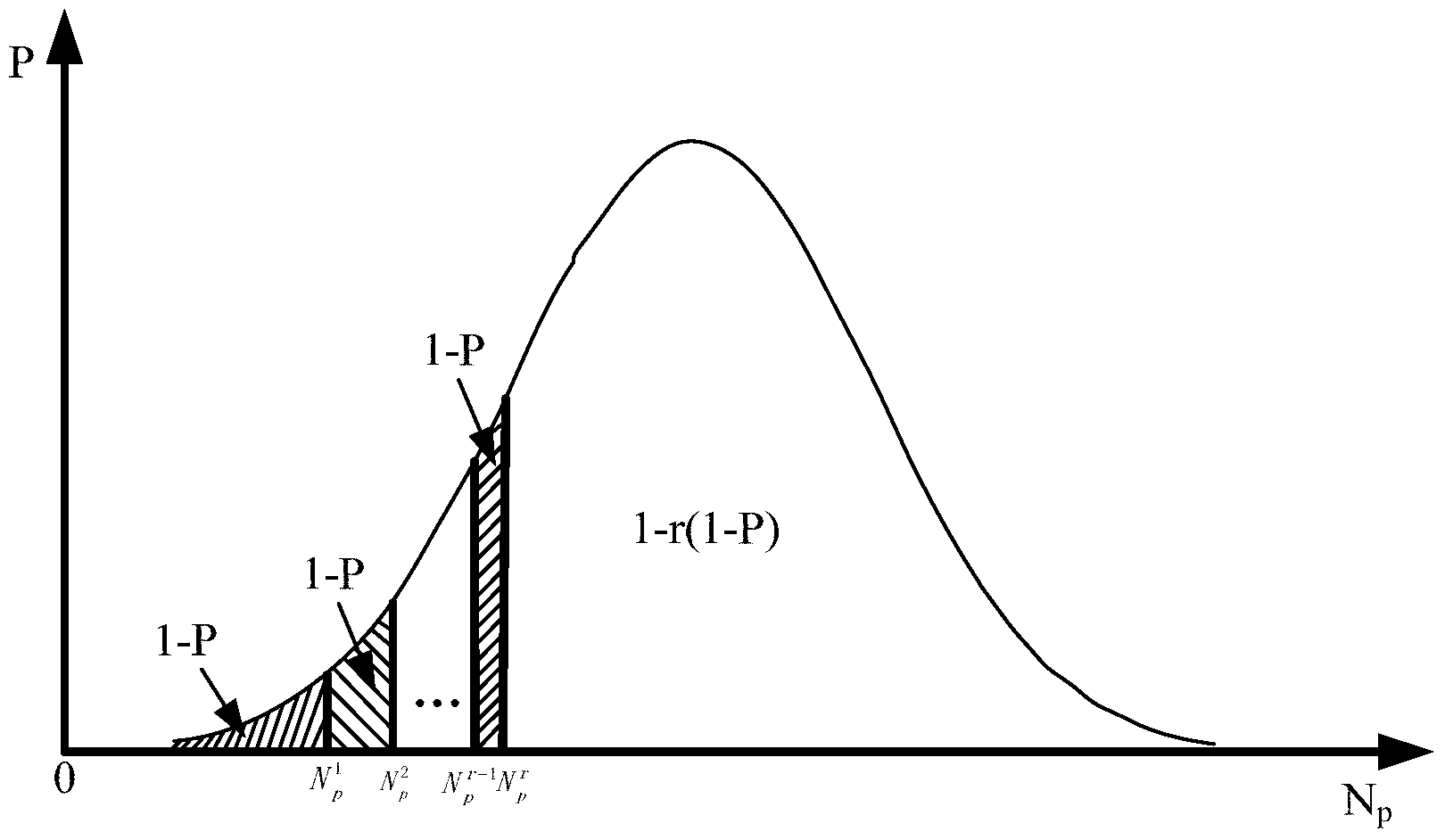

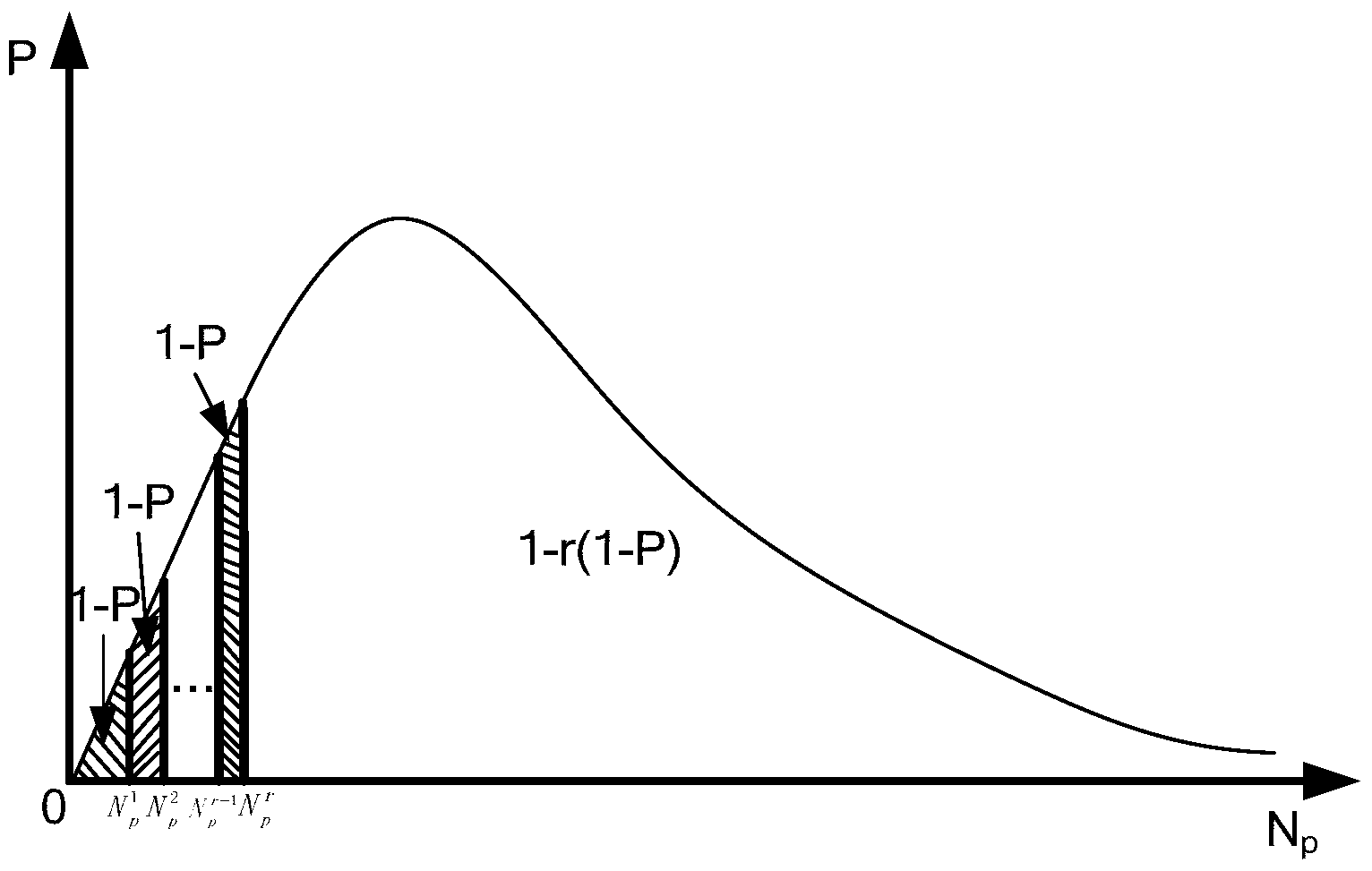

Method used

Image

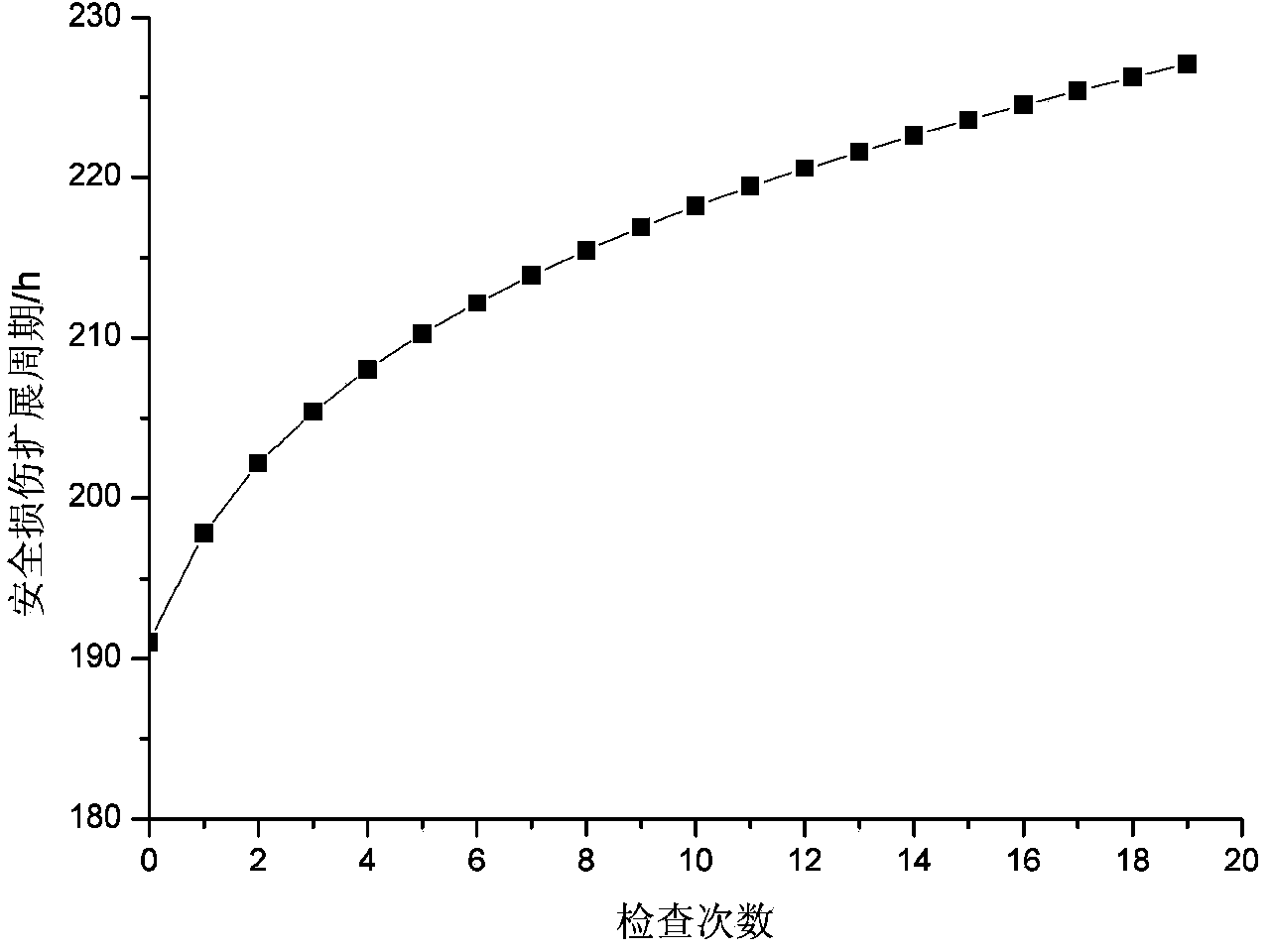

Examples

Embodiment

[0088] A method for determining the safe damage propagation period of aircraft structure fatigue cracks based on inspection and repair times, the specific steps are as follows:

[0089] Step 1): median period of crack growth [N 50 ] of OK.

[0090] Determine the median period of crack growth based on the results of the structural crack growth test [N 50 ]. Assume that the structural crack growth test results of n test pieces are: N 1 ,...,N n .

[0091] When the crack growth life follows a lognormal distribution: it is known to those skilled in the art that the crack growth median period [N 50 ]for:

[0092] [ N 50 ] = 10 Σ i = 1 n 1 g N i ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com