Aluminum alloy solar energy assembly frame

A technology for solar modules and aluminum alloys, applied in electrical components, photovoltaic power generation, photovoltaic modules, etc., can solve the problems of inability to form a unified conduction mode, reduced energy utilization, poor correlation, etc., to achieve convenient installation, convenient conductive devices, reduce cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

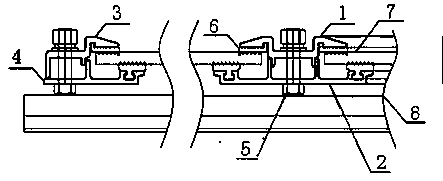

[0008] Depend on figure 1 , a double-glass frameless solar module, consisting of an upper press block 1, a lower press block seat 2, a side press block 3, a side press block seat 4, a T-bolt 5, an EPDM strip 6, a double-glass assembly 7 and a bracket Profile 8, the middle part of the double glass component 7 is fixed by the upper block 1 and the lower block seat 2, the four sides are fixed by the side block 3 and the side block seat 4, and then assembled with the aluminum alloy bracket to form a fastening double Glass frameless components. EPDM rubber strips 6 are added between the upper pressing block 1 and the lower pressing block seat 2, and between the side pressing block 3 and the side pressing block seat 4, and are fastened with T-shaped bolts 5. The side briquetting block 3 can be fixed by entering the cavity of the upper briquetting block 1 through the corner code, and the flying wing parts of the side profiles on the upper briquetting block 1 and the side briquetting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com