Insert for slot milling

一种嵌件、铣槽的技术,应用在铣刀、铣床设备、铣削切削刀片等方向,能够解决切削嵌件和铣刀破损、错误安装切削嵌件、不方便使用等问题,达到防止破损、提高加工质量、满足顾客需求的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

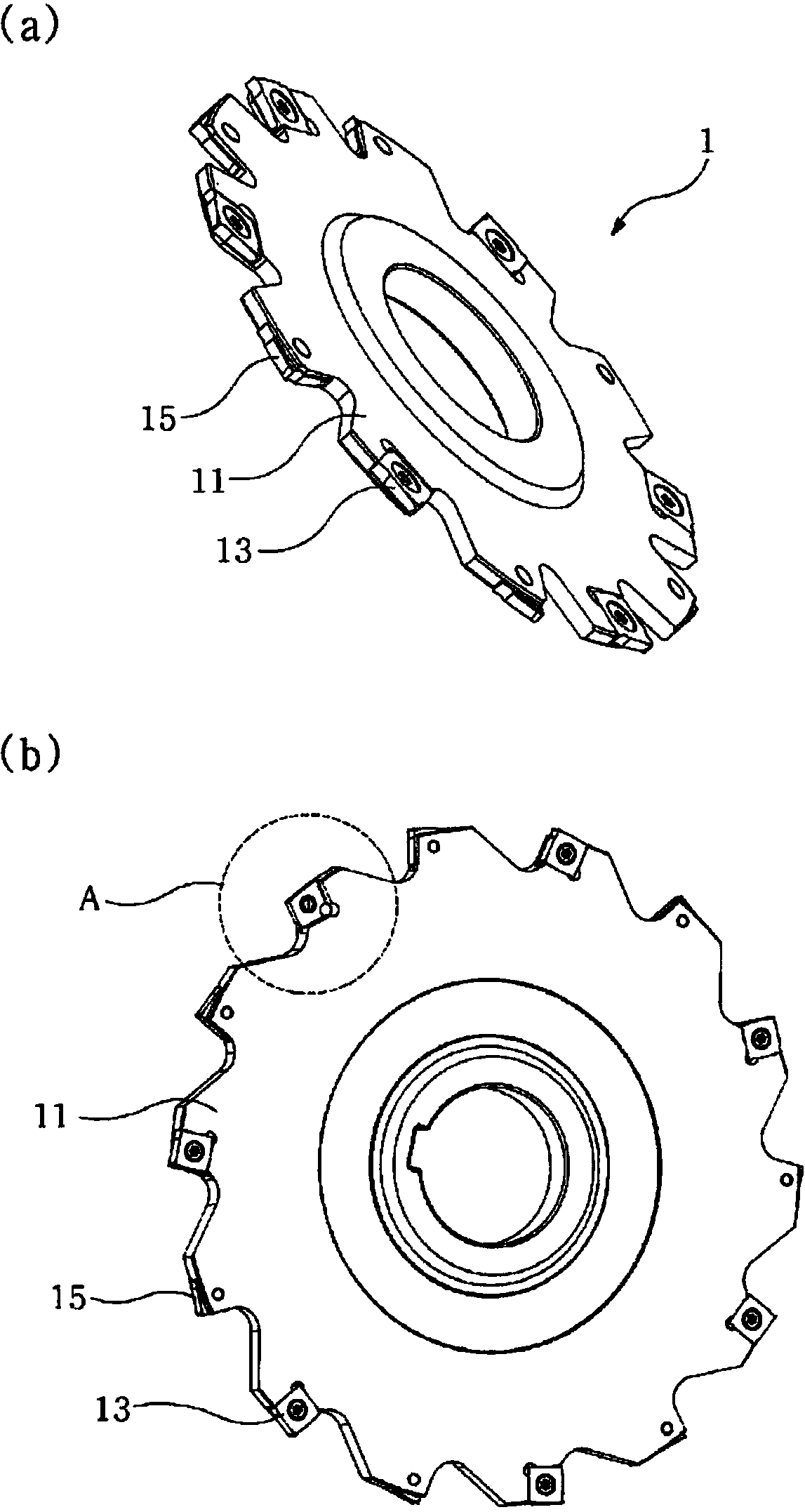

[0034] Hereinafter, the rotary milling cutter of the present invention will be described in detail with reference to the drawings.

[0035] image 3 It is a schematic perspective view of the structure of the rotary milling cutter equipped with the insert of this invention.

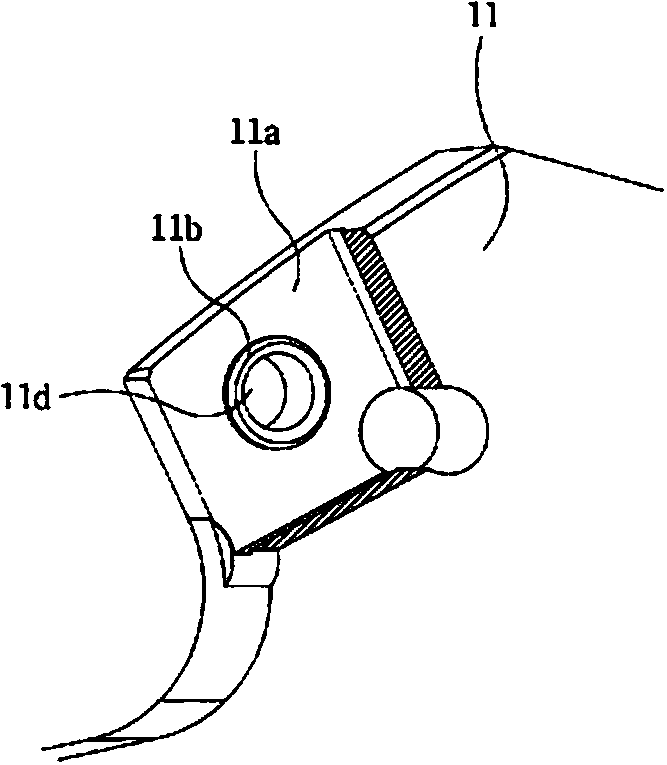

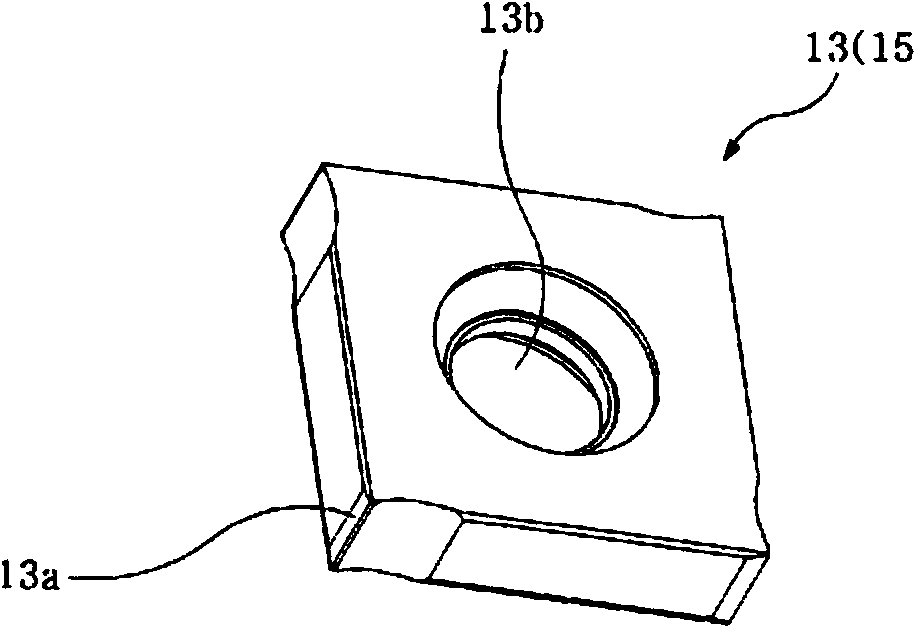

[0036] Figure 4 a to Figure 4 c is a schematic diagram for explaining the structure of the cutting insert according to the present invention and the state in which the cutting insert is coupled to the insert mounting seat of the milling cutter.

[0037] Figure 5 a and Figure 5 b is a schematic diagram of a case where the cutting insert of the present invention is correctly attached to the insert mounting seat of the milling cutter and a case where the cutting insert is incorrectly attached.

[0038] First, if Figure 3 to Figure 4 As shown in c, the cutting insert 50 of the present invention is installed on the cutting insert mounting seat 130 provided on the main body 110 of the milling cutter 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com