Tobacco leaf grading method

A grading method and tobacco leaf technology, applied in tobacco, tobacco preparation, application, etc., can solve the problems of low grading accuracy and high labor intensity of manual grading tobacco leaves, and achieve the effects of improving grading quality, reducing labor intensity, and improving grading accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

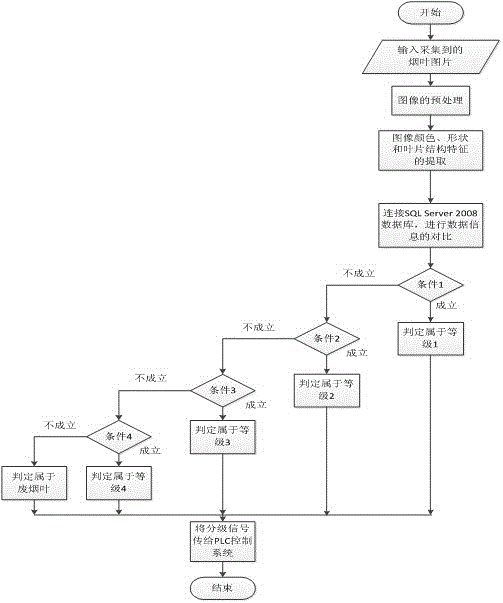

[0019] As shown in the figure, the specific implementation method is as follows:

[0020] A method for grading tobacco leaves, comprising the following steps:

[0021] 1. Create a tobacco leaf grading standard database;

[0022] ①. Collect tobacco leaves of different standard grades, then take pictures of tobacco leaves of each standard grade and input the digital images into the computer;

[0023] ②. Process and analyze the images of tobacco leaves of various standard grades by computer, and extract the characteristic parameters of tobacco leaves;

[0024] 3. Store the characteristic parameters of each standard grade tobacco leaf extracted in the corresponding data table in the established tobacco leaf classification standard database to form a complete tobacco leaf classification standard database;

[0025] 2. Grading treatment of tobacco leaves;

[0026] ①. Collect the picture information of the tobacco leaves to be detected and input it into the computer;

[0027] ②. P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com