Automatic quick rice noodle boiling machine

A powder cooking machine and automatic technology, applied in cooking utensils, household utensils, applications, etc., can solve the problems of time-consuming and laborious, low work efficiency, sorting out two bowls, etc., to reduce secondary pollution and improve overall efficiency , the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

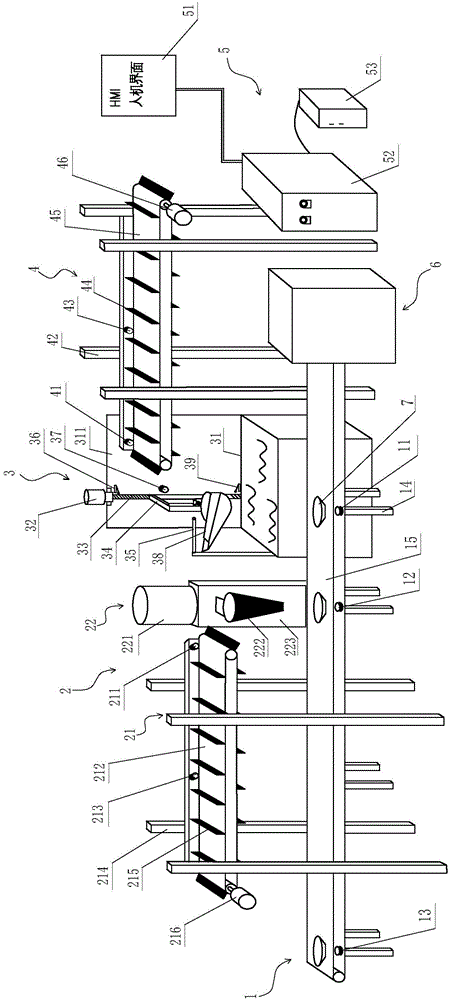

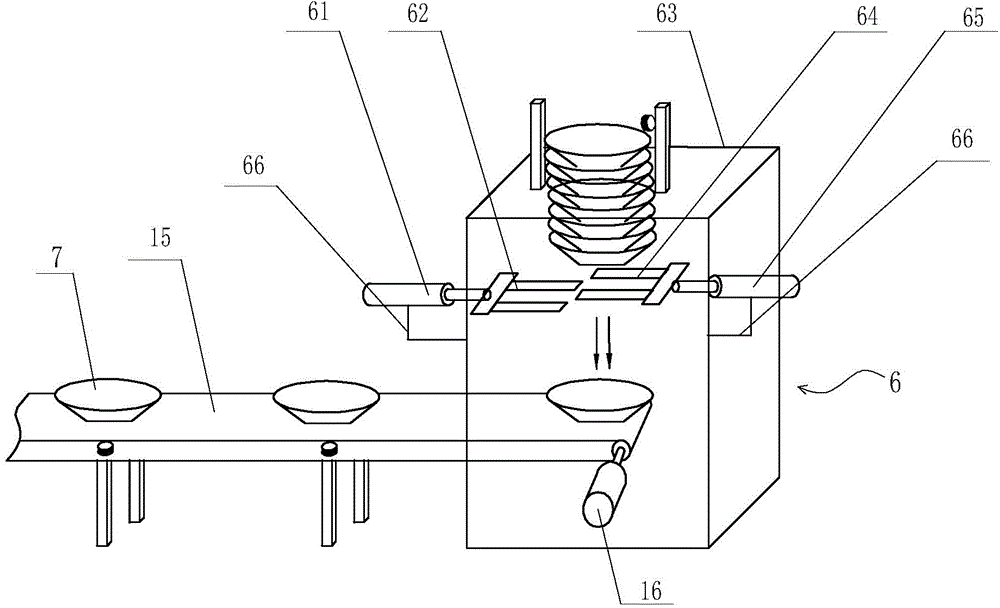

[0019] Such as Figure 1 to Figure 5 As shown, the fast automatic noodle cooking machine of the present invention includes a feeding bowl mechanism 6, a conveying bowl mechanism 1, a rice noodle conveying mechanism 4, a rice noodle scalding mechanism 3, a material feeding mechanism 2, and a central control mechanism 5.

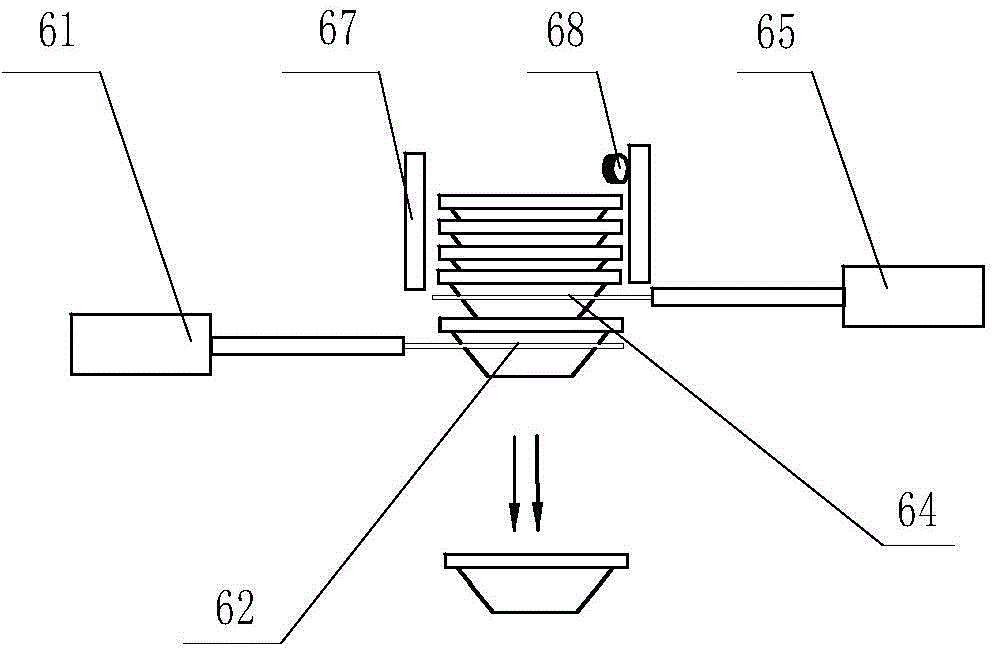

[0020] The bowl delivery mechanism 6 includes a linear motor I61, a linear motor II65, a separating blade I62, a separating blade II64, and a cupboard 63. The linear motor I61 and the linear motor II65 are respectively arranged on opposite sides of the cupboard 63, wherein the linear motor I61 and linear motor II65 are respectively installed on the opposite side walls of cupboard 63 through motor brackets 66. Of course, as a transformation form of the present invention, linear motor I61 and linear motor II65 can also be installed on the side walls of cupboard 63 in other ways. As can be installed by the motor installation hole that directly forms in cupboard 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com