Full-automatic food processing system

A food processing and fully automatic technology, applied in cooking utensils, household utensils, applications, etc., can solve problems such as inaccurate amounts of seasonings and auxiliary materials, difficult to ensure hygienic conditions, and uneven powder quality, so as to ensure the taste and achieve Full automation, the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be further described in detail below in conjunction with the accompanying drawings, which are explanations rather than limitations of the present invention.

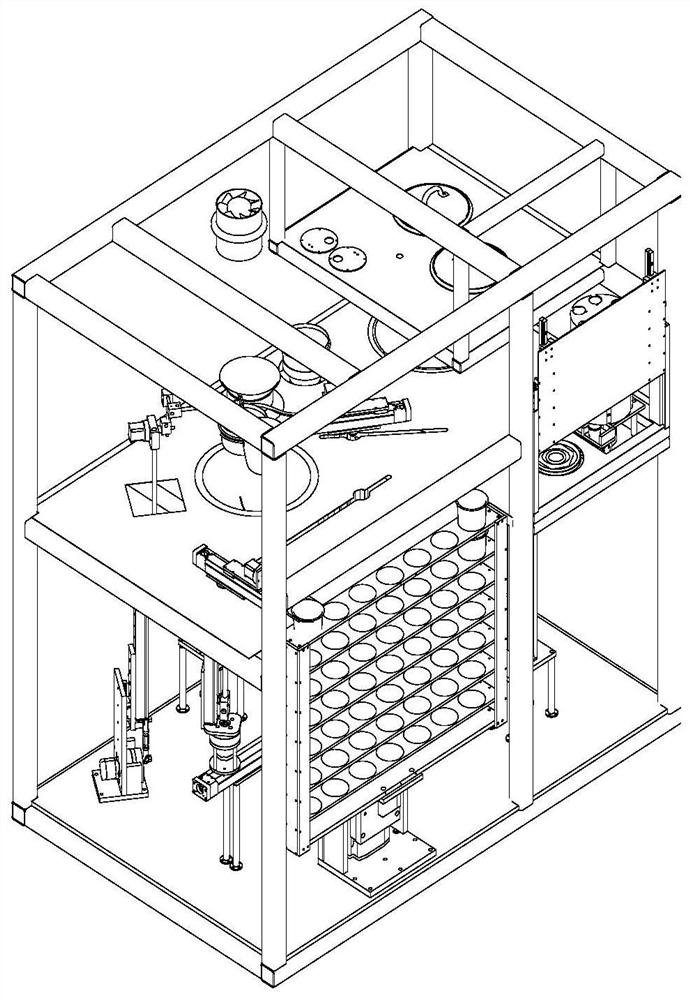

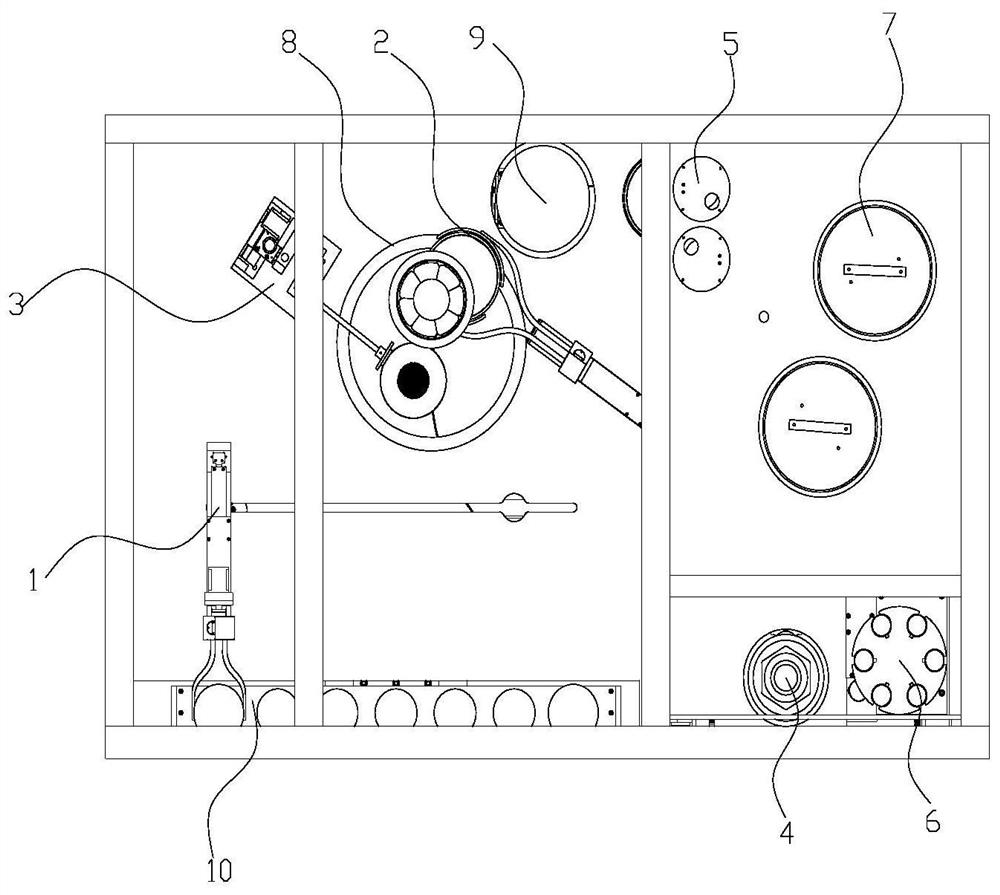

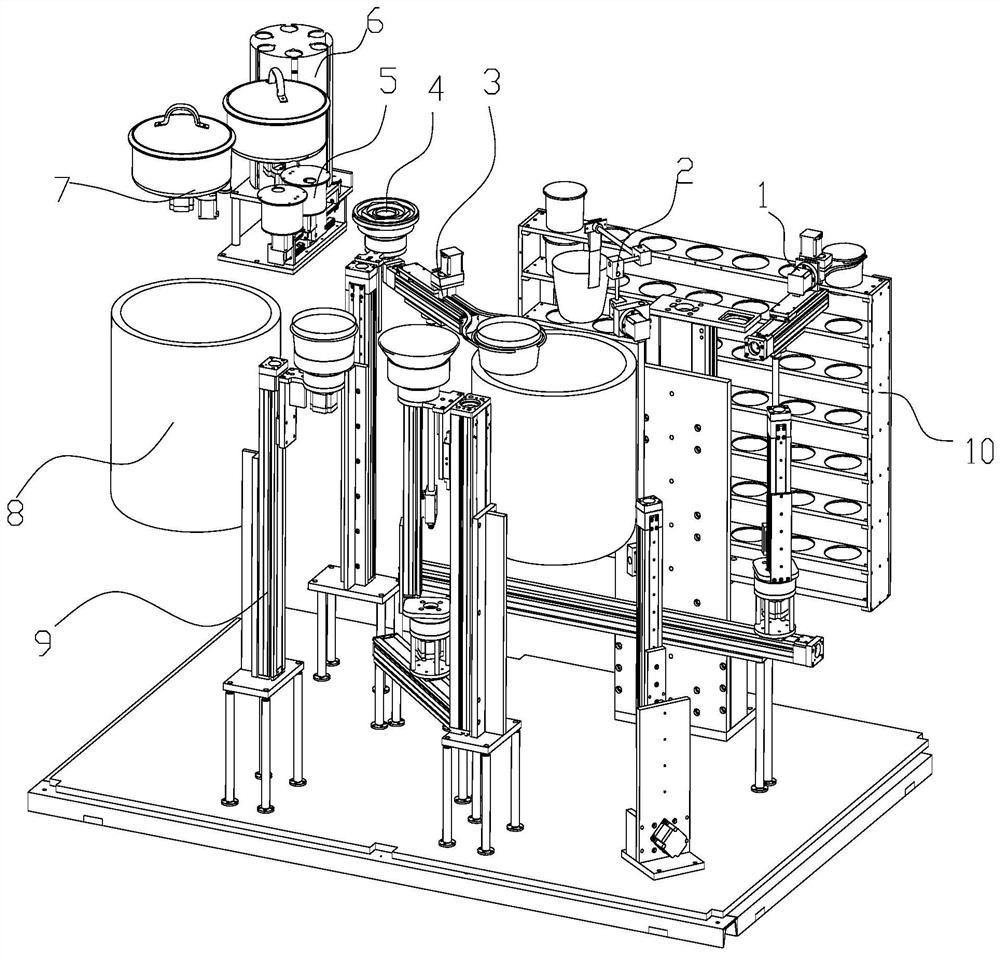

[0055] refer to Figure 1-17 , a fully automatic food processing system, including a processing chamber, which is provided with two supporting partitions inside, and divides the processing chamber into three layers from top to bottom.

[0056] The upper layer of the processing bin is provided with a seasoning adding device 5 and a supplementary food feeding device 7, the middle layer of the processing bin is provided with a soup bucket 8, a heating pot and a small material conveying device 6, and the middle layer of the processing bin is provided with a meal outlet, and the meal outlet An electric control door is provided, and the lower layer of the processing chamber is provided with a material lifting frame 10, a material holding device 1, a swinging device 2, a conveying device 3, a b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com