Backwash filtering device of rolled oil of stainless steel rolling mill

A technology of backwashing and filtering and rolling oil, which is applied in the direction of filtration and separation, fixed filter elements, chemical instruments and methods, etc. It can solve problems such as single structure, poor utilization of rolling oil, and insufficient filtering capacity, and achieve the goal of filtering High precision, good efficiency, improve the effect of secondary utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

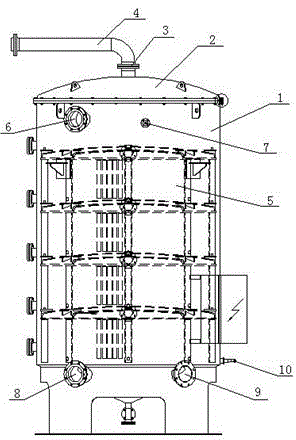

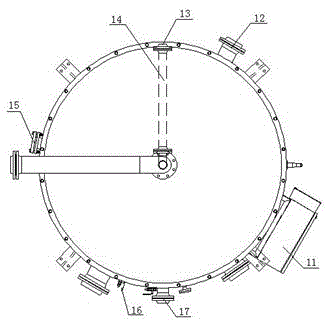

[0017] Such as figure 1 , 2 As shown, a stainless steel mill rolling oil backwash filtering device includes a filter cartridge body 1, a filter cartridge body 1 is equipped with a filter cartridge body 2, and an air port 3 is provided on the filter body body 2, and is connected to There are steel pipes 4; the filter cartridge body 1 is provided with a filter plate 5, and there are 4 filter plates 5, which are divided into 4 layers, and each layer has 832 backwash filter elements; the filter plate 5 is arc-shaped; the filter The upper part of the cartridge body 1 is also provided with an overflow port 6 and a filter plate flushing oil port 7; Peep holes 15 are provided on the upper end of each filter plate 5 on the filter cartridge body 1 . The filter cartridge body 1 is provided with a copper ball valve 16 for installing a differential pressure transmitter. An air control box 11 is provided on the filter cartridge body 1 for centralized installation of air control valves an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com