Inner welding brush cover production process

A production process, internal welding technology, applied in manufacturing tools, welding equipment, welding equipment, etc., can solve the problems of uneven solder joints, low internal welding efficiency, large brush gap, etc., and achieve cylindricity and cone errors. Reduced, improved production efficiency, beautiful and neat solder joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

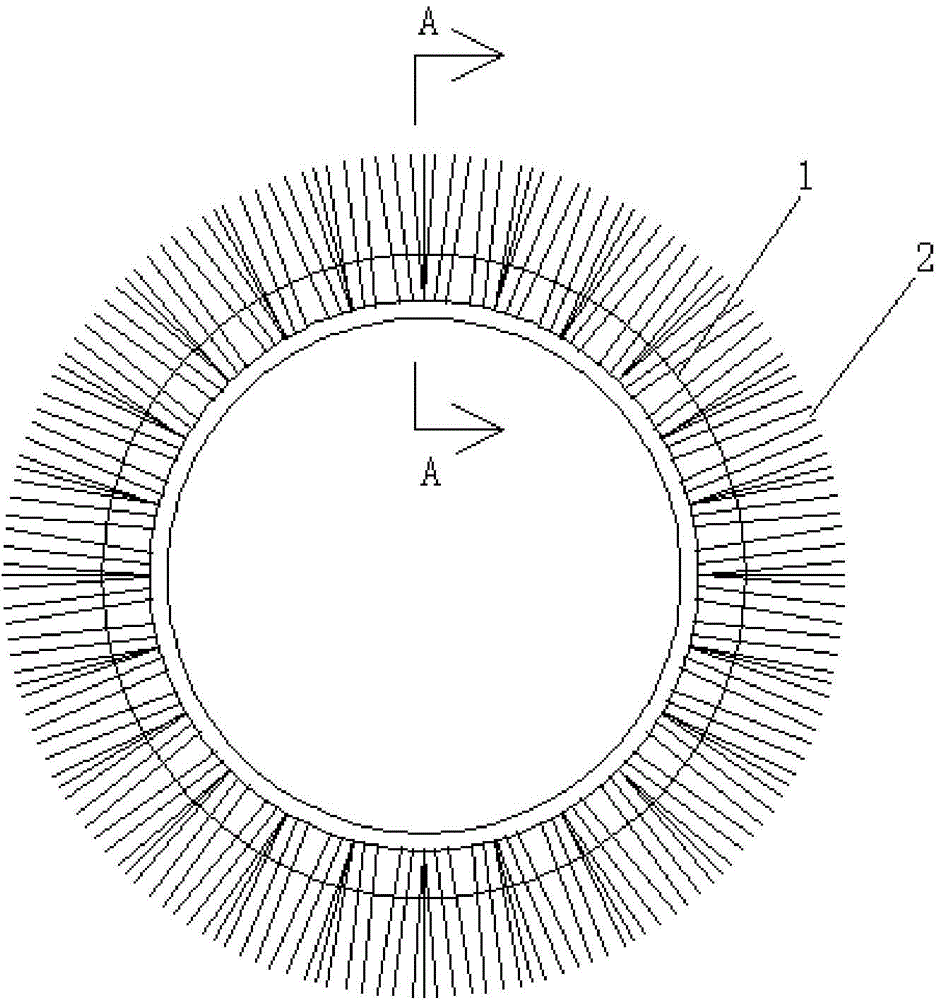

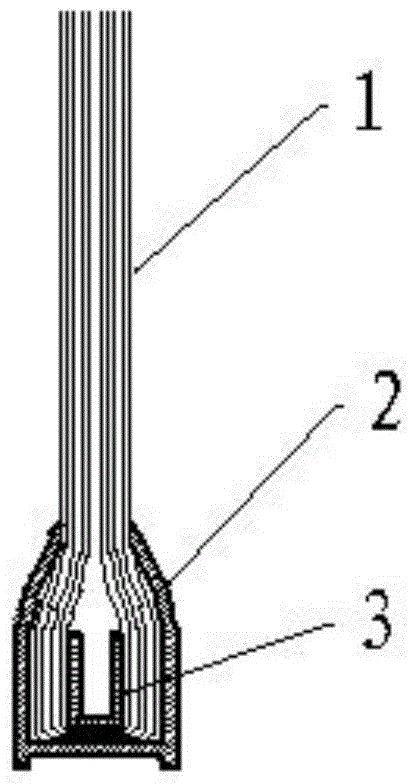

[0011] Referring to the accompanying drawings, a production process of an internally welded brush cover includes a brush wire 1 constituting a brush cover, an outer steel strip 2 and an inner steel strip 3. A pressure wheel group composed of two pressure wheels presses the steel belt into a U-shaped brush strip with a fixed width, and the brush wire is evenly distributed between the inner and outer steel belts. When the steel belt and the brush wire pass through the pressure wheel group, the pressure The wheel set presses the inner and outer steel belts tightly to fix the brush wire. The brush sleeve is supported by a fully automatic internal welding support mold. The support mold leaves a gap at the connection of the brush sleeve, and the welding tip of the automatic cantilever welding manipulator protrudes through the gap. The welding points are welded. The brush cover is cylindrical and assembled section by section. Both ends are fixed with pins and locked with round nuts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com