Double-station riveting machine of permanent magnet type claw pole stepping motor speed reducer

A deceleration device and stepping motor technology, which is applied in the direction of assembly machines, manufacturing tools, metal processing equipment, etc., can solve the problems of motor deceleration device coordination, increased labor intensity, and prone to industrial accidents, etc., to achieve a high degree of automation, The effect of improving production efficiency and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

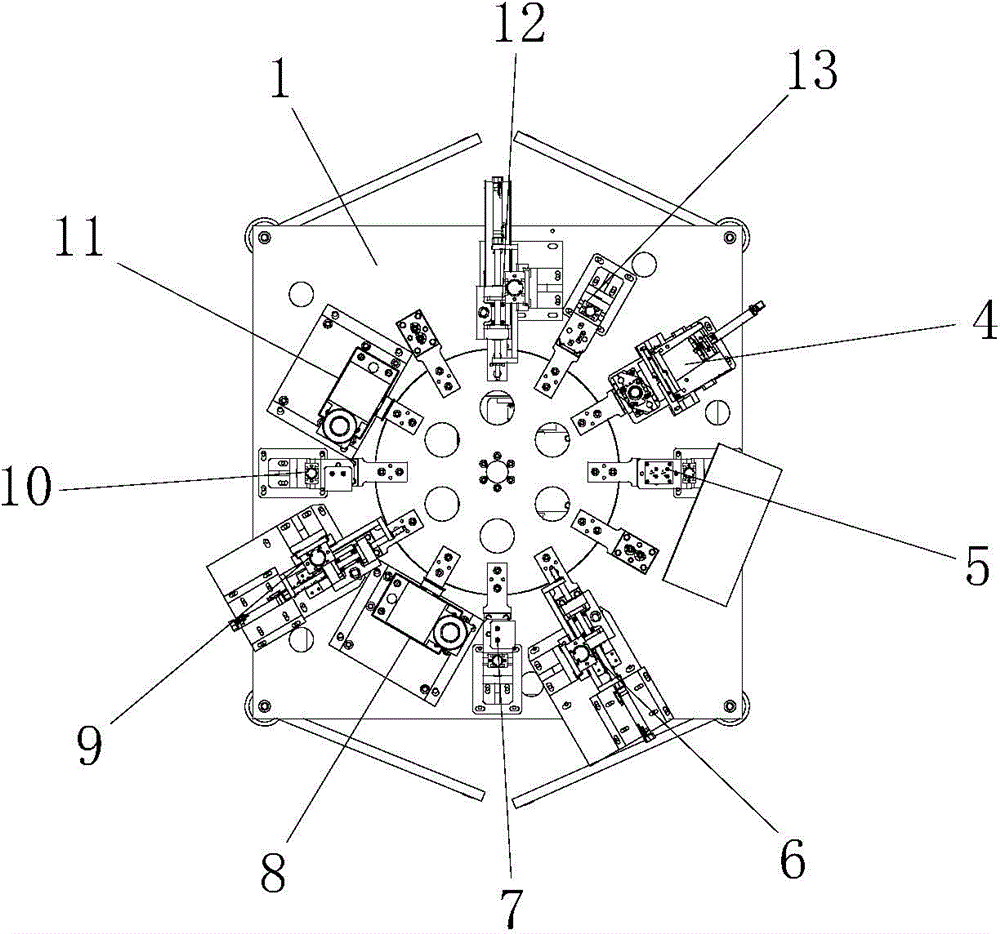

[0022] refer to Figure 1 to Figure 8 , a double-station riveting machine with a permanent magnet claw pole type stepping motor reduction device, including a machine platform 1, characterized in that a rotating disc 2 is installed on the machine platform 1, and a rotating disc 2 is installed on the rotating disc 2. There are a number of tooling positions 3, and the rotating disk 2 is connected with a rotating disk power mechanism to drive it to rotate. There are needle feeding mechanism 4, needle detection mechanism 5, gear plate feeding mechanism 6, first preload guiding mechanism 7, riveting mechanism 8, magnetic plate feeding mechanism 9, second preload guiding mechanism 10, and riveting mechanism 11. The material return mechanism 12 and the material return detection mechanism 13 .

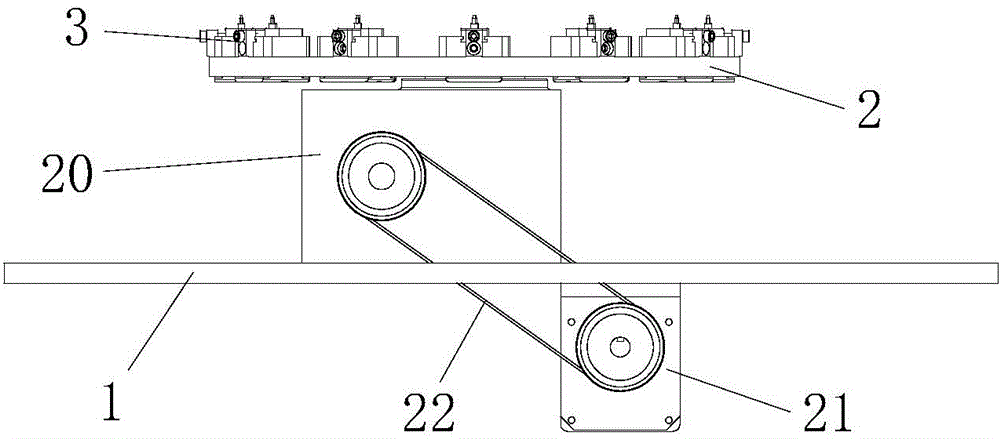

[0023] refer to figure 2 , the turntable power mechanism includes a special-shaped cam splitter 20 installed on the machine table 1, the rotating disk 2 is installed on the output shaft of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com