Hexagonal drilling and tapping machine

A technology for drilling and tapping machines and bearing housings, which is applied to metal processing machinery parts, clamping, supporting, etc. It can solve problems such as unreliable reliability, many positioning actions, and complicated mechanisms, and achieve low manufacturing costs and fast transposition speed , The simple effect of the displacement mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

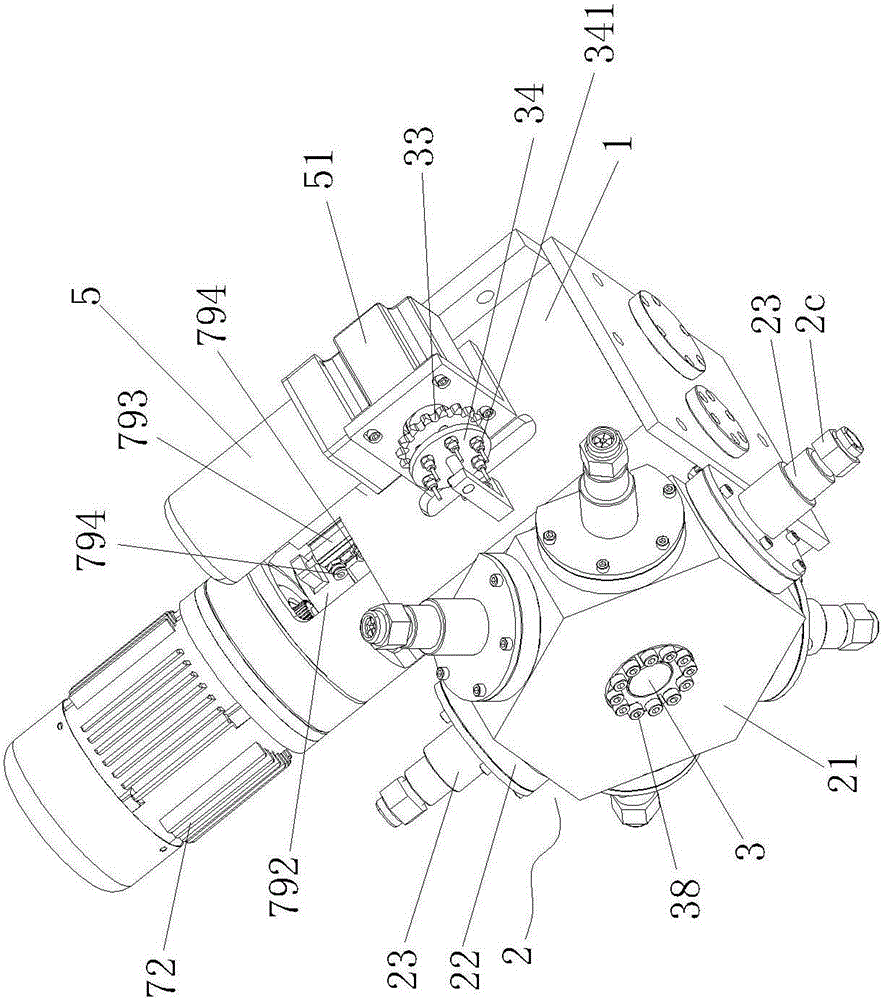

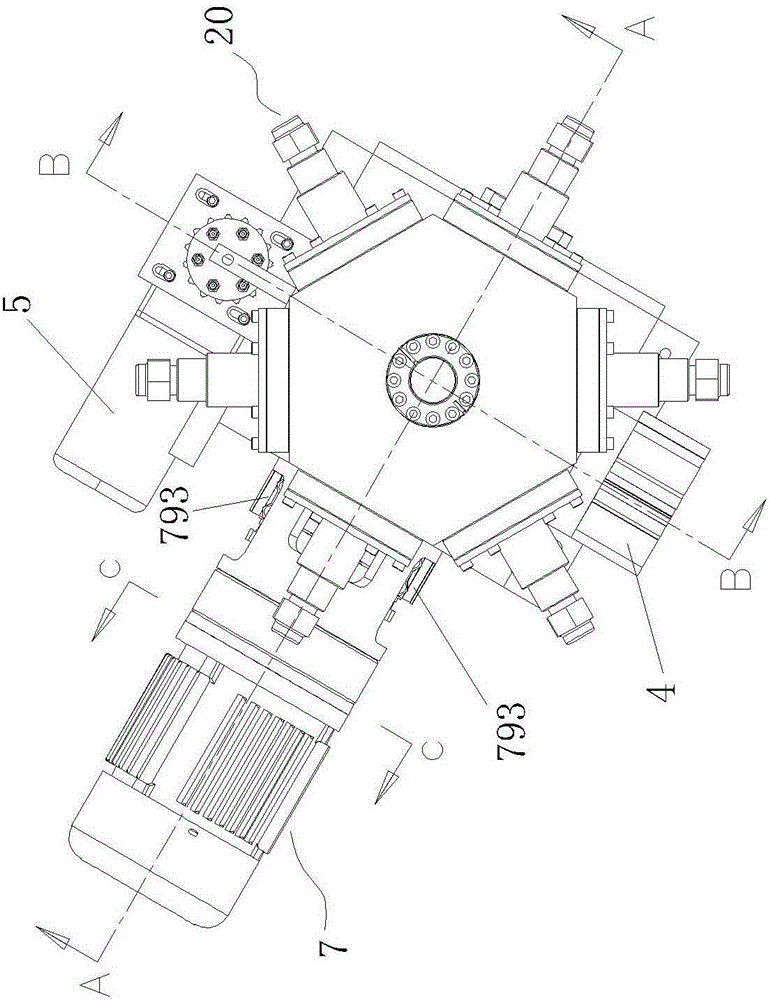

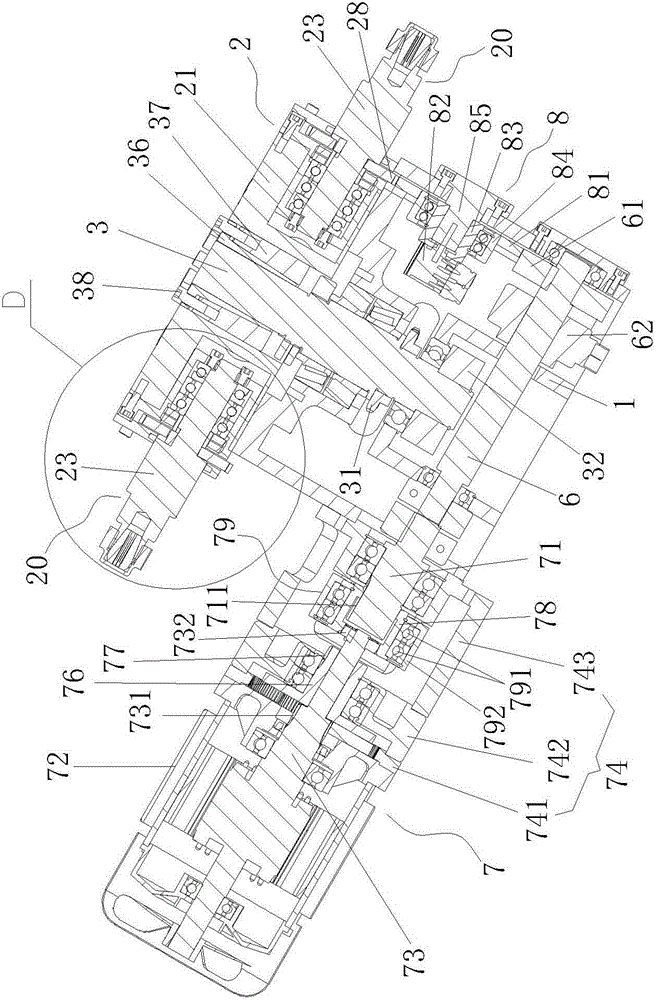

[0039] Figure 1 to Figure 18 As shown, a hexagonal drilling machine includes a box body 1, a turret 2, and a central shaft 3. The middle part of the central shaft 3 is pivotally connected to the box body 1 through three centripetal bearings. The turret 2 includes a six Angle turntable 21 and six sets of main shaft mechanisms 20 fixed on the six sides of hexagon turntable 21, hex turntable 21 are affixed to the front part of central axis 3.

[0040] The main shaft mechanism 20 includes a first bearing seat 22 and a main shaft 23 pivotally connected to the first bearing seat 22. The first bearing seat 22 is stepped cylindrical, and the rear part of the main shaft 23 is sleeved on the first bearing seat 22. In the central hole of the main shaft 23, two radial bearings 24 are installed between the rear part of the main shaft 23 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com