Foam composite pad base material

A composite pad and foam material technology, applied in synthetic resin layered products, layered products, rubber layered products, etc., can solve the problems of poor comfort, insufficient supporting strength, high hardness, etc., and achieve good stability and stability. The effect of support, good softness to contact, good elasticity and recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

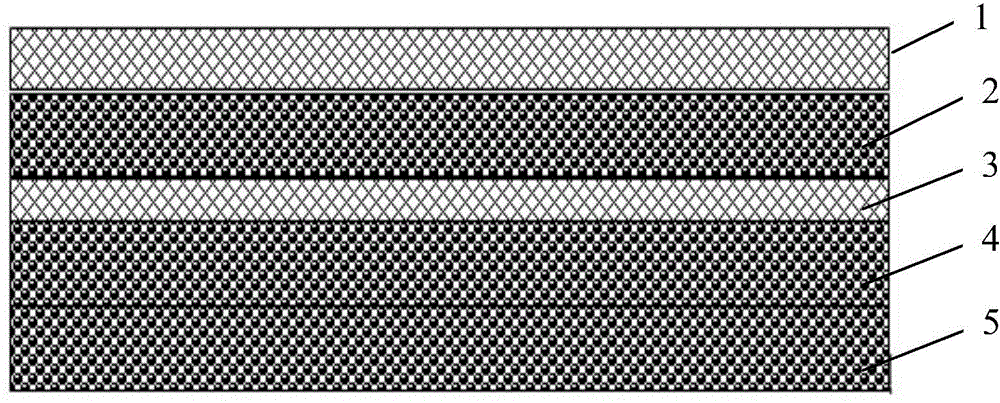

[0021] Such as figure 1 As shown, the base material of this composite mat is composed of five layers, and the density is 50kg / m from top to bottom. 3 1. A polyethylene cross-linked open-cell foam layer 1 with a thickness of 7.5 mm and a density of 40 kg / m 3 1. A polyethylene cross-linked closed-cell foam layer 2 with a thickness of 10 mm and a density of 50 kg / m 3 1. A polyethylene cross-linked open-cell foam layer 3 with a thickness of 5 mm and a density of 60 kg / m 3 1. A polyethylene cross-linked closed-cell foam layer 4 with a thickness of 10 mm and a density of 60 kg / m 3 1. A polyethylene cross-linked closed-cell foam layer 5 with a thickness of 10 mm.

[0022] The above-mentioned five-layer foamed materials are coils or sheets before they are compounded. First, the polyethylene cross-linked open-cell foam layer 1 and the polyethylene cross-linked closed-cell foam layer 2 are thermally compounded by a flame compounding machine to obtain Composite layer 1; polyethylene ...

Embodiment 2

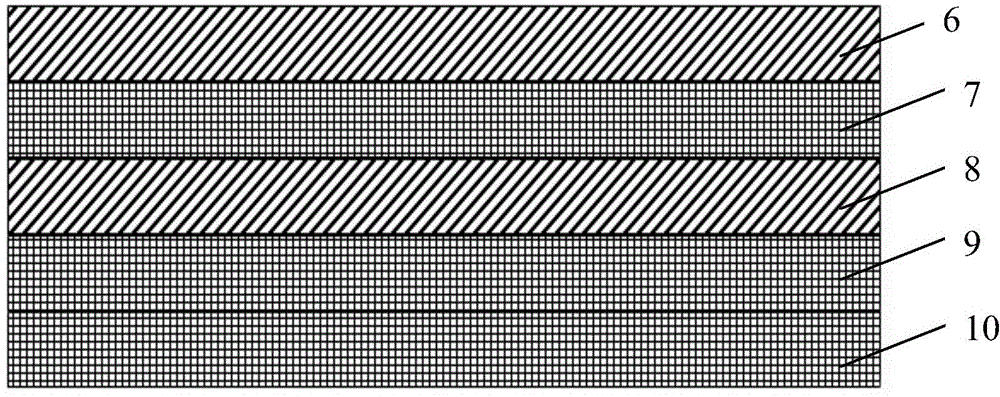

[0024] Such as figure 2 As shown, the composite mat base material is composed of five layers, and the density is 80kg / m from top to bottom. 3 1. A polyethylene cross-linked open-cell foamed plastic layer 6 with a thickness of 10 mm and a density of 60 kg / m 3 , EPDM closed-cell foam rubber layer 7 with a thickness of 10mm and a density of 60kg / m 3 1. A polyethylene cross-linked open-cell foamed plastic layer 8 with a thickness of 10 mm and a density of 60 kg / m 3 1. A polyethylene cross-linked open-cell foamed plastic layer 9 with a thickness of 10 mm and a density of 80 kg / m 3 1. An EPDM closed-cell foam rubber layer 10 with a thickness of 10 mm.

[0025] The above five layers of foamed materials are coils or sheets before they are compounded. First, the polyethylene cross-linked open-cell foamed plastic layer 6 and the EPDM closed-cell foamed rubber layer 7 are thermally compounded by a flame compounding machine. , to obtain composite layer one; polyethylene cross-linked ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com