A car electric sunroof

A sunroof, electric technology, applied in the direction of vehicle parts, engine components, engine sealing, etc., can solve the problems of weak drainage, complex assembly process, poor sealing effect, etc., to achieve fewer parts, simple assembly process, and reduce the number Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

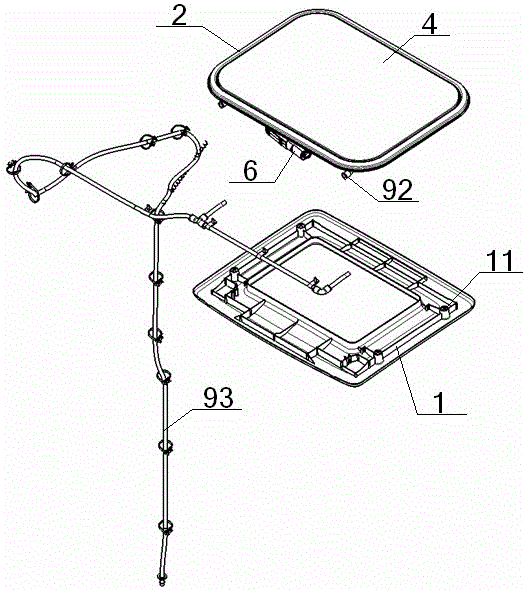

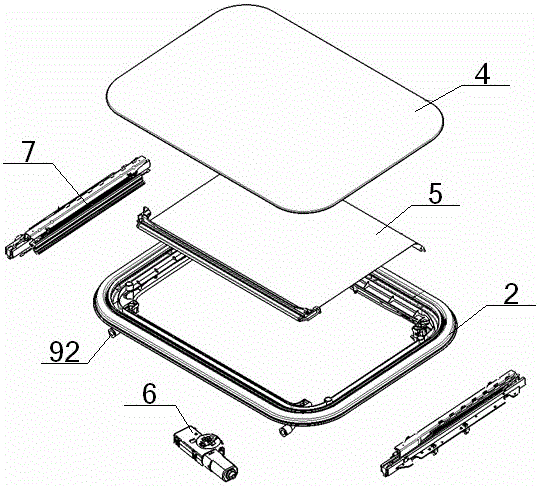

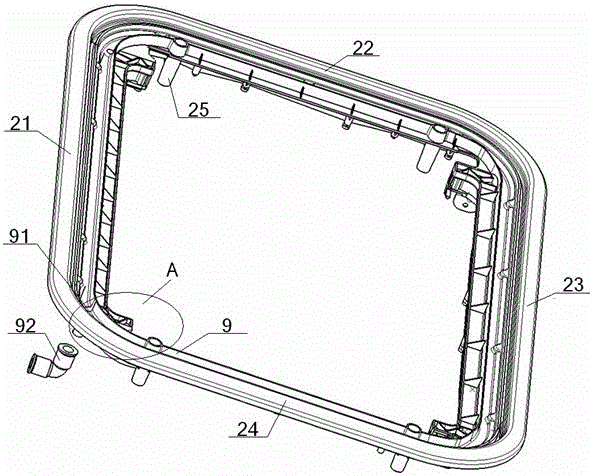

[0045] see figure 1 – Figure 7 , an automobile electric sunroof, comprising a lower shield 1, a sunroof frame 2, a sealing strip 3, a glass 4, a sunshade 5, a control motor 6 and a rail mechanism 7;

[0046] The skylight frame 2 includes No. 1 short beam 21, No. 1 long beam 22, No. 2 short beam 23, and No. 2 long beam 24 connected in sequence. No. 1 short beam 21 and No. 2 short beam 23 are arranged in parallel. The long beam 22 and the No. 2 long beam 24 are arranged in parallel; the bottoms of the No. 1 short beam 21 and the No. 2 short beam 23 are respectively provided with a guide rail mechanism 7, and a control motor is arranged at the bottom of the No. 2 long beam 24 6. The flexible shaft 61 in the control motor 6 is respectively coupled with the sunshade slider 51 and the lifting arm 41 through the guide rail slider 71 on the guide rail mechanism 7. The sunshade slider 51 is connected with the sunshade curtain 5, and the The warping arm 41 is connected to one end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com