Automatic loading and stacking integrated machine of goods

An all-in-one machine and palletizing technology, which is applied in the field of automatic cargo loading and unloading equipment, can solve the problems of unsuitable for large-area warehouses, low loading efficiency, and narrow application range, so as to save loading time, improve loading efficiency, and use wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

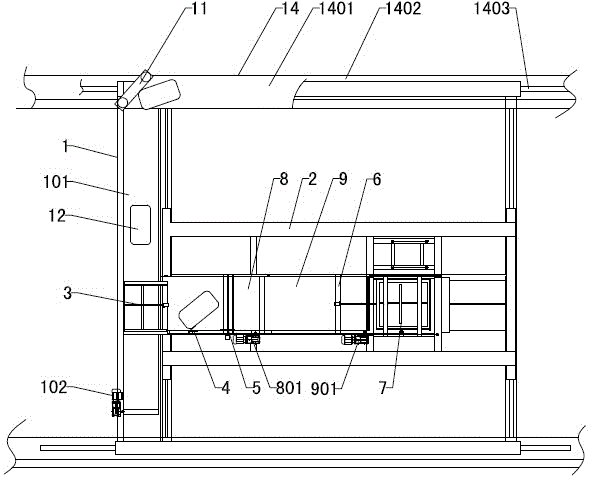

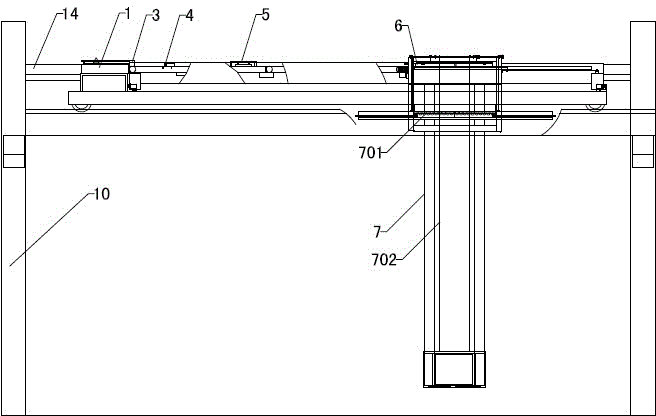

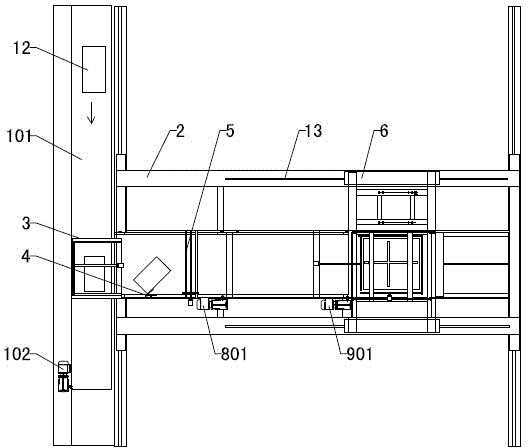

[0028] Figure 1~6 It is the best embodiment of the present invention, below in conjunction with attached Figure 1~6 The present invention will be further described.

[0029] Refer to attached Figure 1~3 : The integrated machine for automatic loading and stacking of goods includes a longitudinal belt conveying mechanism 1, a horizontal conveying mechanism, an adjusting mechanism 4, a stacking and marshalling device 5, a positioning mechanism 6, a loading and palletizing mechanism 7 and a switchboard running mechanism 14. One side of the longitudinal belt conveying mechanism 1 is provided with a transverse conveying mechanism perpendicular to it, and the two sides of the transverse conveying mechanism can move horizontally along one side of the longitudinal belt conveying mechanism 1 through a transverse sliding device, and the two conveying ends of the longitudinal belt conveying mechanism 1 are vertically There is a switchboard running mechanism 14, and the longitudinal bel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com