Elevator brake performance whole process real-time monitoring control system and using method

An elevator brake and real-time monitoring technology, which is applied in elevators, hoisting devices, transportation and packaging, etc., can solve the problems of no safety guarantee, achieve the effects of reducing maintenance costs, preventing accidents, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

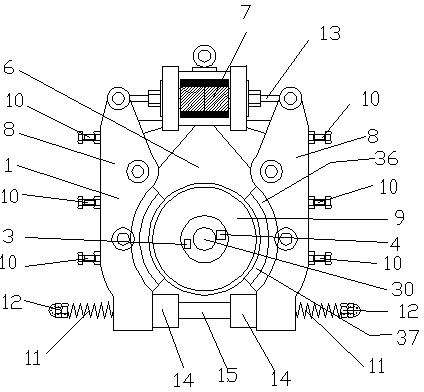

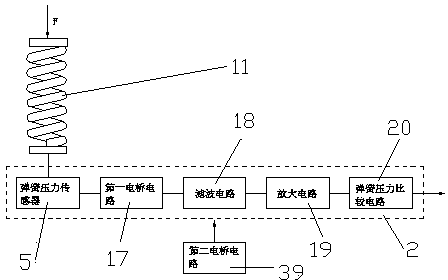

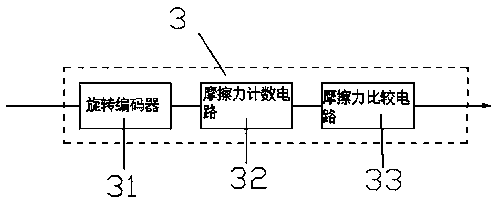

[0025] Such as Figure 1-5 As shown, an elevator brake performance real-time monitoring and control system throughout the whole process and its use method include an elevator brake 1 on which a spring pressure detection system 2, a friction force detection system 3 and a braking frequency detection system 4 are respectively installed.

[0026] The elevator brake 1 includes a bracket 6 on which an electromagnet 7, two brake arms 8, and a brake wheel 9 are installed respectively. The electromagnet 7 is located between the two brake arms 8 , and the electromagnet 7 is used for restoring the brake spring 11 . The brake wheel 9 is located between the two brake arms 8, a rotating shaft 30 is installed on the brake wheel 9, and a friction detection system 3 and a brake frequency monitoring system are installed between the brake wheel 9 and the rotating shaft 30. In system 4, positioning bolts 10, brake pads 36 and braking springs 11 are respectively installed on the brake arm 8, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com