Front-cleaning rail middle-trough multi-azimuth conveyer

A multi-directional, handling machine technology, applied in cranes and other directions, can solve the problems of slow installation and disassembly, difficult transportation in the middle tank, high labor intensity, etc., to achieve flexible use, reduce labor intensity, and improve installation and disassembly speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

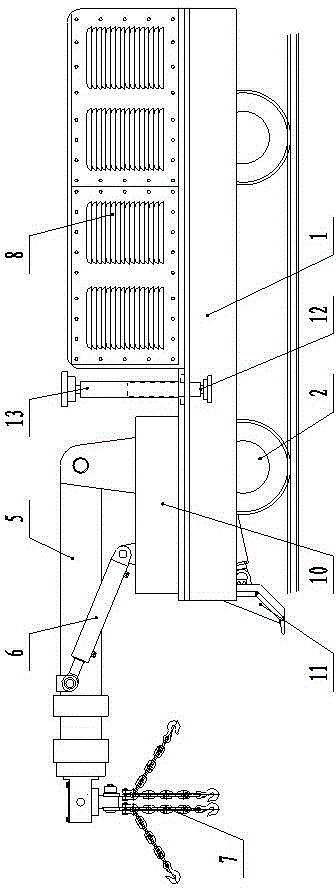

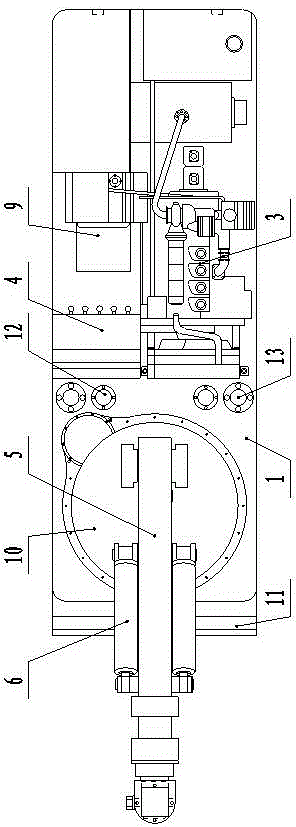

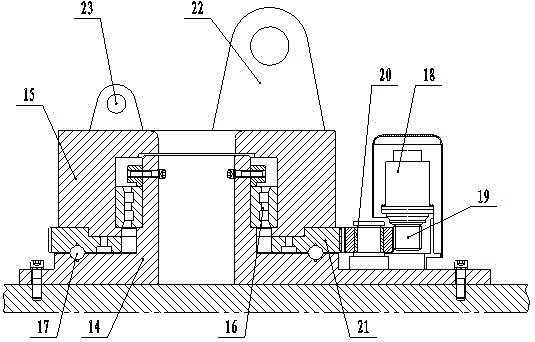

[0019] like Figure 1-3 As shown, the front cleaning rail-type middle groove multi-directional transporter of the present invention includes a frame 1, a rail-type wheel set 2, an explosion-proof diesel engine 3, a hydraulic system, a console 4, a boom component 5, a boom cylinder 6, and a bucket 11 and turntable 10, the bottom of frame 1 is equipped with multiple groups of track-type wheel sets 2, boom parts 5 are installed on the front part of frame 1 through turntable 8, turntable 10 is fixedly installed on the front part of frame 1, boom parts The rear end of 5 is hinged on the turntable 10 and the front end of the boom part 5 is provided with a chain hook 7, the cylinder body of the boom cylinder 6 is hinged on the turntable 10, the piston rod end of the boom cylinder 6 and the boom part The middle part of 5 is hinged, and the rear part of the frame 1 is equipped with an explosion-proof diesel engine 3 and a hydraulic system that provide power, and the boom cylinder 6 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com