Wheel type middle trough handling device

A handling device, wheeled technology, applied in the directions of transportation and packaging, underground transportation, earth-moving drilling, etc., can solve the problems of slow installation and disassembly, difficult transportation in the middle tank, high labor intensity, etc., to achieve stable work, lightening Labor intensity, the effect of increasing the speed of installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

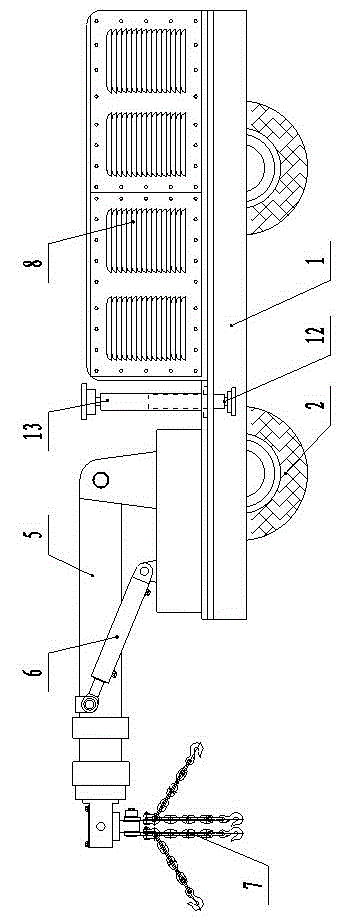

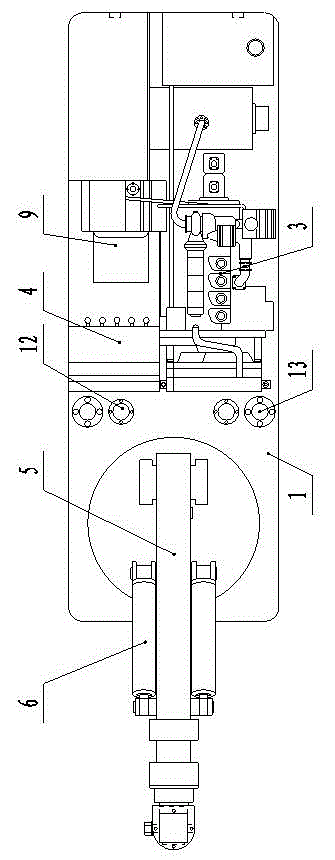

[0015] Such as Figure 1-2 As shown, the wheeled middle groove handling device of the present invention comprises a frame 1, a solid tire group 2, an explosion-proof diesel engine 3, a hydraulic system, a console 4, a boom part 5 and a boom oil cylinder 6, and the bottom of the frame 1 is equipped with Multiple groups of solid tire groups 2, the rear end of the boom part 5 is hinged on the front part of the frame 1 and the front end of the boom part 5 is provided with a chain hook 7, the middle part of the boom part 5 and the piston of the boom cylinder 6 The end of the rod is hinged, and the cylinder body of the boom cylinder 6 is hinged on the frame 1. An explosion-proof diesel engine 3 and a hydraulic system providing power are installed at the rear of the frame 1. The boom cylinder 6 is connected to the hydraulic system. The explosion-proof diesel engine 3 upper cover is equipped with protective cover 8, is provided with cooling hole on the protective cover 8, and console ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com