A kind of steel rust inhibitor

A technology of steel bar rust inhibitor and rust inhibitor, which is applied in the field of building materials, can solve the problems of improving the conductivity of unsuitable concrete, accelerating the corrosion of steel bars, corrosion of steel bars, etc., and achieves the effects of avoiding the decline of the protection effect, slowing down the penetration, and improving the performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Steel bar rust inhibitor of the present invention comprises molecular composition and is (1 / 2Ca, Na) 0.7 (Al, Mg, Fe) 4 (Si,Al) 8 o 20 (OH) 4 ·nH 2 O Silicate minerals, the usage amount is 0.5% of the quality of the cementitious material in the concrete, 1-amino-8-naphthol-3,6-disulfonic acid monosodium salt, the dosage is 0.5% of the quality of the cementitious material in the concrete 0.10%, the amount of thiourea is 0.15% of the quality of the cementitious material in the concrete, the amount of dicyclohexylamine nitrite is 0.25% of the quality of the cementitious material in the concrete, and the amount of fly ash is 0.15% of the quality of the cementitious material in the concrete 1.25%.

Embodiment 2

[0017] Steel bar rust inhibitor of the present invention comprises molecular composition and is (1 / 2Ca, Na) 0.7 (Al, Mg, Fe) 4 (Si,Al) 8 o 20 (OH) 4 ·nH 2 O Silicate minerals, the usage amount is 1.0% of the quality of the cementitious material in concrete, 1-amino-8-naphthol-3,6-disulfonic acid monosodium salt, the dosage is 1% of the quality of the cementitious material in the concrete 0.30%, the amount of thiourea is 0.30% of the quality of the cementitious material in concrete, the amount of dicyclohexylamine nitrite is 0.40% of the quality of the cementitious material in concrete, and the amount of fly ash is 0.30% of the quality of the cementitious material in concrete 1.75%.

Embodiment 3

[0019] Steel bar rust inhibitor of the present invention comprises molecular composition and is (1 / 2Ca, Na) 0.7 (Al, Mg, Fe) 4 (Si,Al) 8 o 20 (OH) 4 ·nH 2 O Silicate minerals, the usage amount is 0.8% of the quality of the cementitious material in the concrete, 1-amino-8-naphthol-3,6-disulfonic acid monosodium salt, the dosage is 0.8% of the quality of the cementitious material in the concrete 0.20%, the amount of thiourea is 0.20% of the quality of the cementitious material in concrete, the amount of dicyclohexylamine nitrite is 0.30% of the quality of the cementitious material in concrete, and the amount of fly ash is 0.2% of the quality of the cementitious material in concrete 1.50%.

[0020] The steel bar corrosion rapid test method is used to test the steel bar corrosion of different gel materials. The raw materials include standard cement, standard sand, and fly ash.

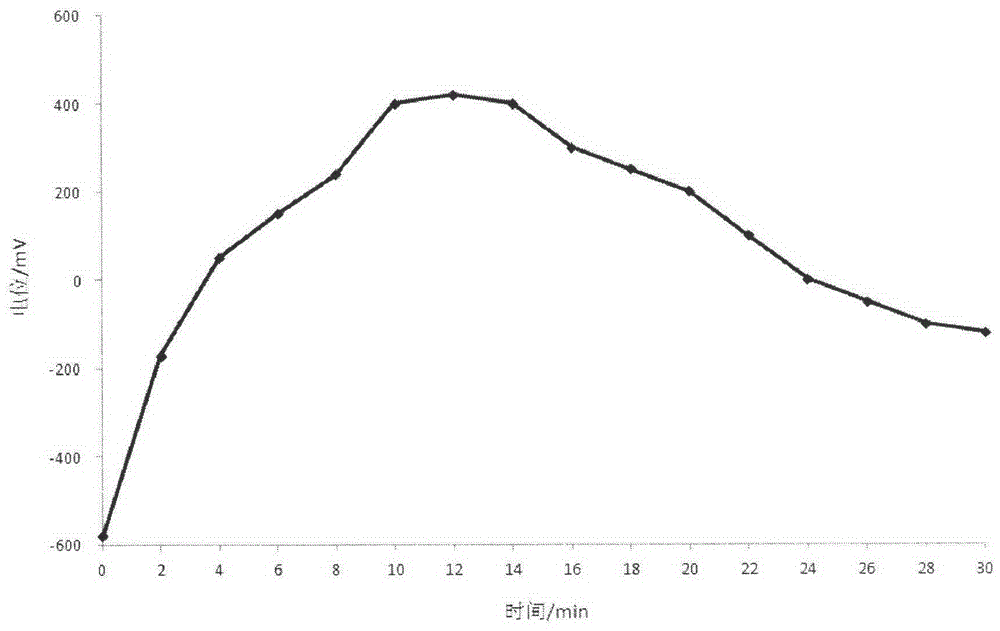

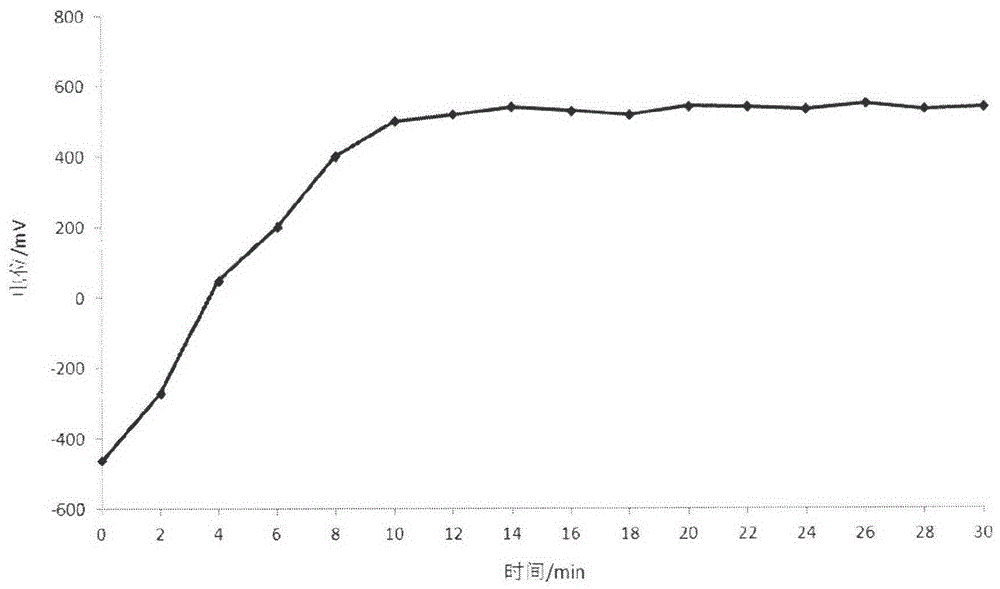

[0021] from figure 1 It can be seen that without adding the rust inhibitor of the present invent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com