Hydrophilic UV (Ultraviolet) coating hardness assistant and preparation method thereof

A hydrophilic and coating technology, applied in the direction of coating, can solve the problems of unstable emulsion performance, low film hardness and high viscosity, and achieve good results, improve acid and alkali resistance, and improve water solubility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Table 1-1 Synthetic raw materials of prepolymer Ⅰ

[0032] name

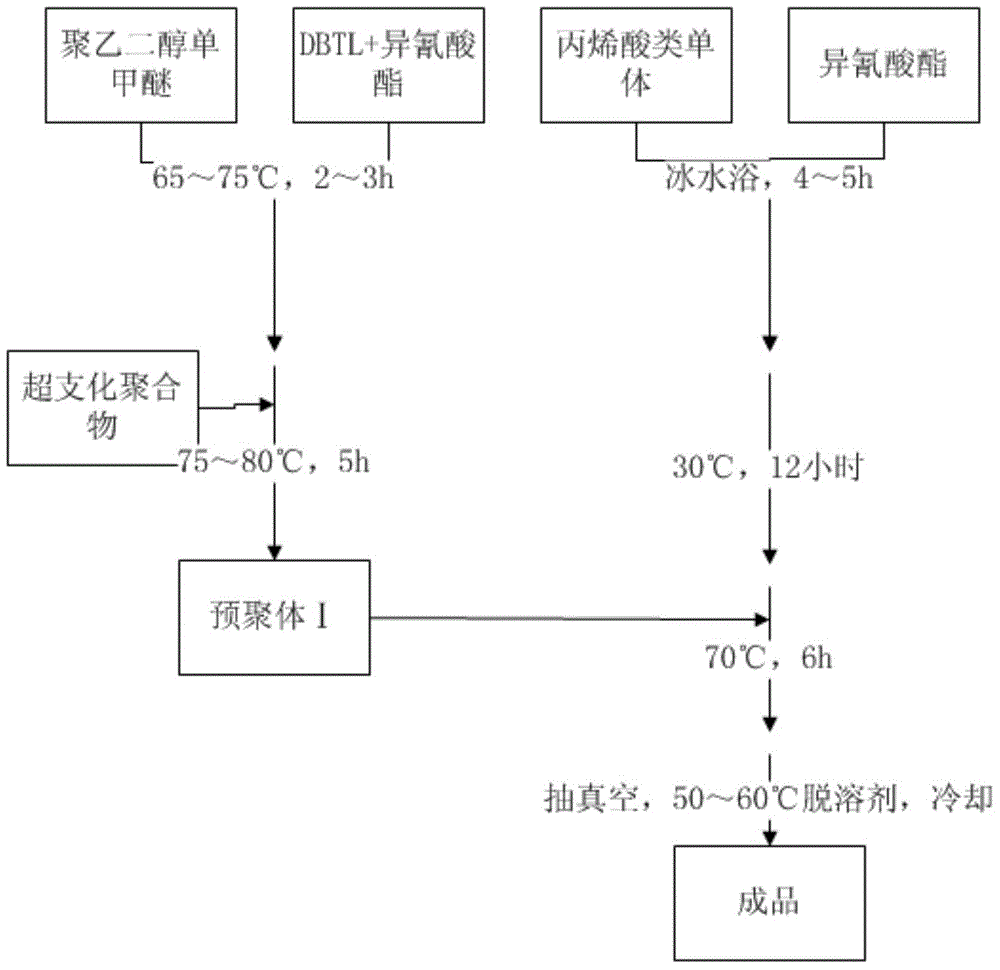

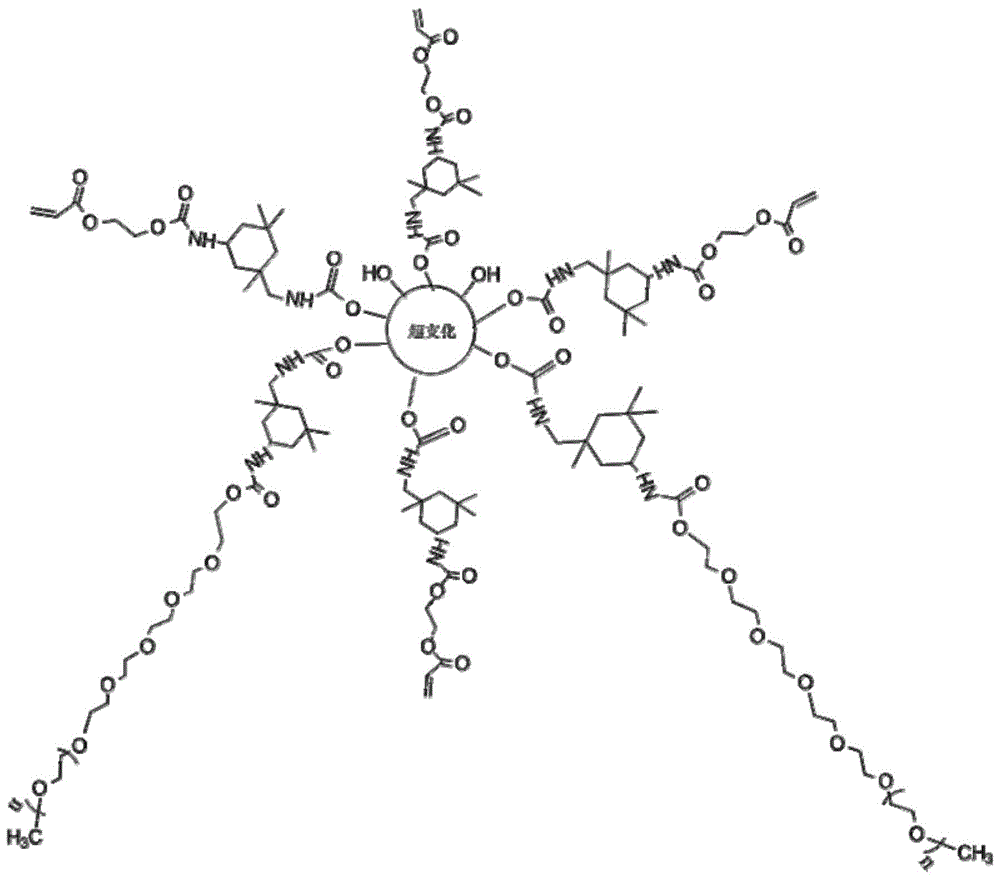

[0033] Remove water from polyethylene glycol monomethyl ether and react with IPDI with catalyst DBTL at 70°C for 2.5 hours, dissolve hyperbranched bis-MPA polyester-8-hydroxyl-1 generation polymer with DMSO and add to the reaction system In the process, the temperature was raised to 75°C, and after 5 hours of reaction, prepolymer I was prepared for use.

[0034] Table 1-2 Synthetic raw materials of two-tailed four-functional hydrophilic UV coating hardness additives

[0035] name

[0036] Dissolve hydroxyethyl acrylate in DMSO, add dropwise reaction with IPDI for 4 hours at ice-water bath temperature, raise the temperature to 30°C and react for 12 hours to obtain the intermediate product, add prepolymer I to the intermediate product, raise the temperature to 70°C, and stir , react for 6 hours, vacuumize, keep the vacuum degree of the reaction system at 0.09MPa, control the temperature...

Embodiment 2

[0038] Table 2-1 Synthetic raw materials of prepolymer Ⅰ

[0039] name

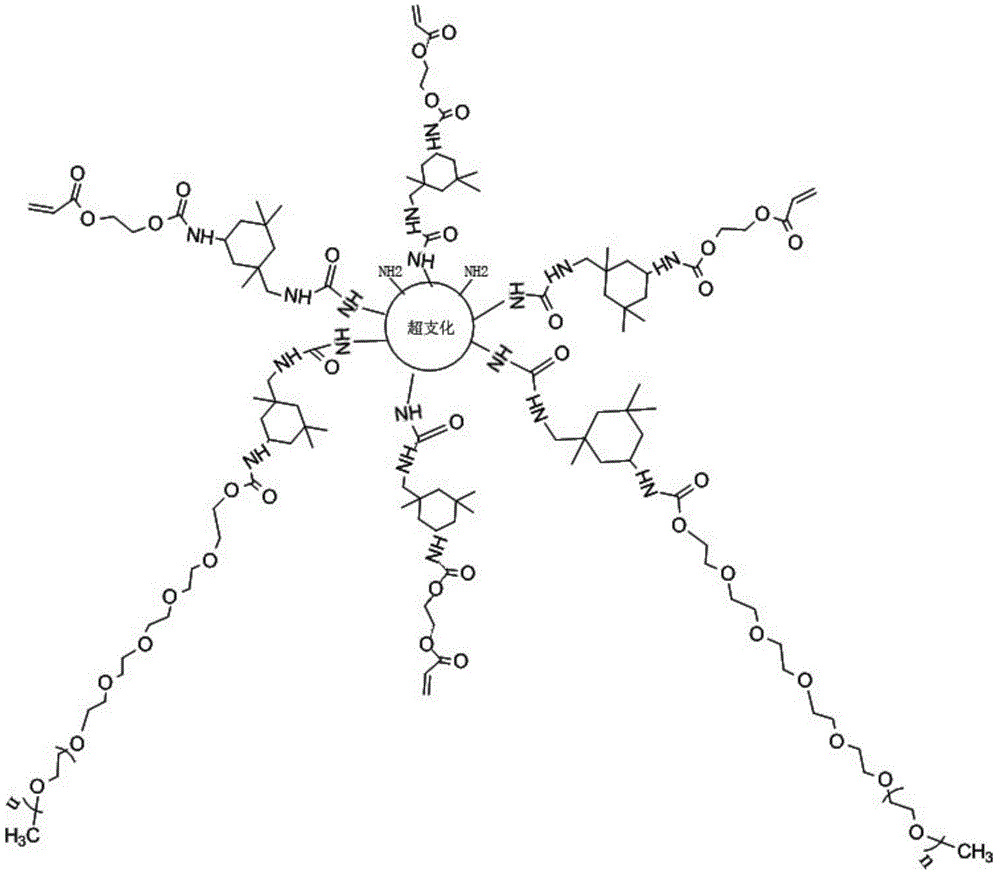

[0040] Remove water from polyethylene glycol monomethyl ether and react with IPDI with catalyst DBTL at 70°C for 2.5 hours, dissolve hyperbranched bis-MPA polyester-8-amino-1 generation polymer with THF and add to the reaction system In the process, the temperature was raised to 75°C, and after 5 hours of reaction, prepolymer I was prepared for use.

[0041] Table 2-2 Synthetic raw materials of two-tailed four-functional hydrophilic UV coating hardness additives

[0042] name

[0043] Dissolve hydroxyethyl methacrylate in THF, add dropwise reaction with IPDI for 4 hours at ice-water bath temperature, raise the temperature to 30°C and react for 12 hours to obtain the intermediate product, add prepolymer I to the intermediate product and raise the temperature to 70°C , stirred, reacted for 6 hours, vacuumed, kept the vacuum degree of the reaction system at 0.09MPa, controlled the temper...

Embodiment 3

[0045] Table 3-1 Synthetic raw materials of prepolymer Ⅰ

[0046] name

quality

Polyethylene glycol monomethyl ether (number average molecular weight 4000)

40.0g

IPDI

2.22g

Hyperbranched bis-MPA Polyester-8-Hydroxy-1 Generation

14.8g

DBTL

0.8g

DMSO

24.8g

[0047] Remove water from polyethylene glycol monomethyl ether and react with IPDI with catalyst DBTL at 65°C for 3 hours, dissolve hyperbranched bis-MPA polyester-8-hydroxyl-1 generation polymer with DMSO and add to the reaction system In the process, the temperature was raised to 75°C, and after 5 hours of reaction, prepolymer I was prepared for use.

[0048] Table 3-2 Synthetic raw materials of two-tailed four-functional hydrophilic UV coating hardness additives

[0049] name

quality

Hydroxypropyl Acrylate

5.8g

IPDI

8.88g (0.04mol)

Prepolymer I

57.02g

DMSO

30.72g

[0050] Dissolve hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com