Double-steel-plate concrete combined shear wall connected through waveform reinforced bars

A combined shear wall and concrete technology, applied to walls, building components, buildings, etc., can solve problems such as difficult construction and complex structure, and achieve the advantages of convenient construction, reliable combination, high compressive and shear bearing capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

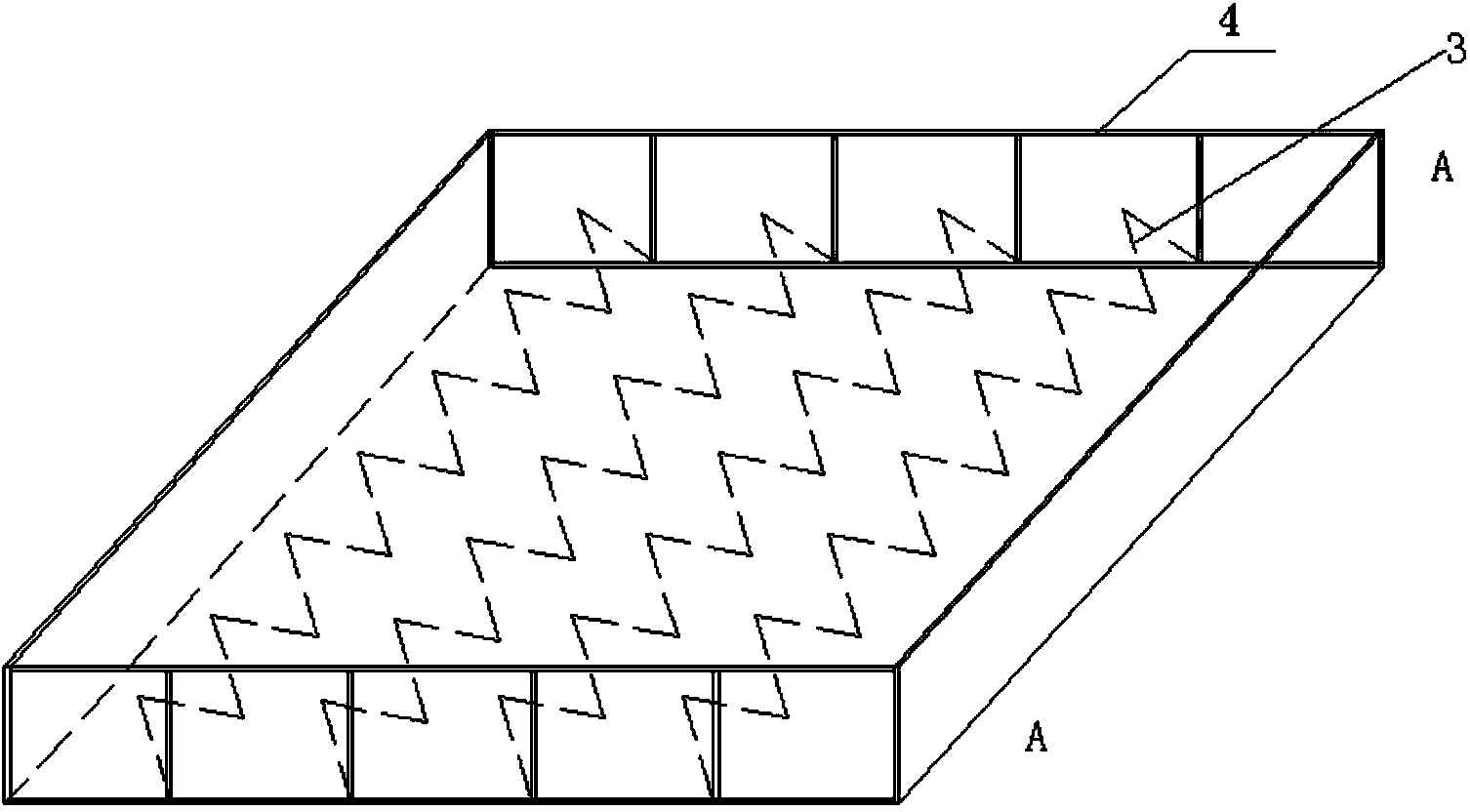

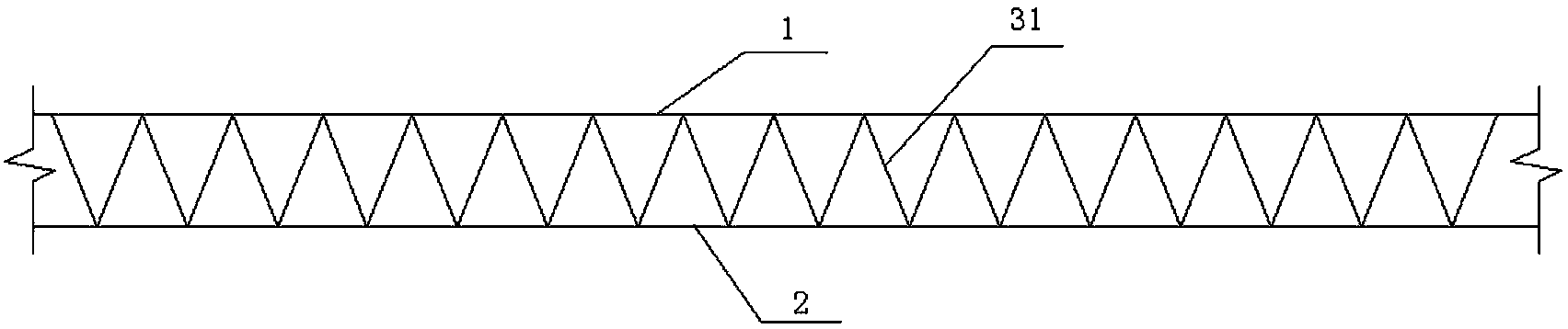

[0013] refer to figure 1 with figure 2 , a double-steel plate concrete composite shear wall connected by corrugated steel bars, comprising a left steel plate 1, a right steel plate 2 and an end partition 4, between the ends of the left steel plate 1 and the right steel plate 2 The end partition 4 is provided, and the left steel plate 1, the right steel plate 2 and the end partition 4 are enclosed to form a box structure, and the box structure has a cavity, and the cavity The cavity is poured with concrete;

[0014] Between the left steel plate 1 and the right steel plate 2, several rows of wavy steel bars 3 are arranged through the longitudinal direction, and the steel bars 3 are composed of continuous broken line segments 31; the joints of adjacent broken line segments 31 is the bending place of the steel bar, and the bending place is located on the upper surface or the lower surface of the box structure.

[0015] Further, the series of steel bars 3 are parallel to each o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com