Cooling device with finned muffler

A heat dissipation device and muffler technology, which is applied in the direction of muffler, exhaust device, machine/engine, etc., can solve the problems of noise reduction, resistance material temperature rise and muffler performance, so as to increase heat dissipation area, enhance effect and reduce weight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below with reference to the embodiments and accompanying drawings, but the embodiments of the present invention are not limited thereto.

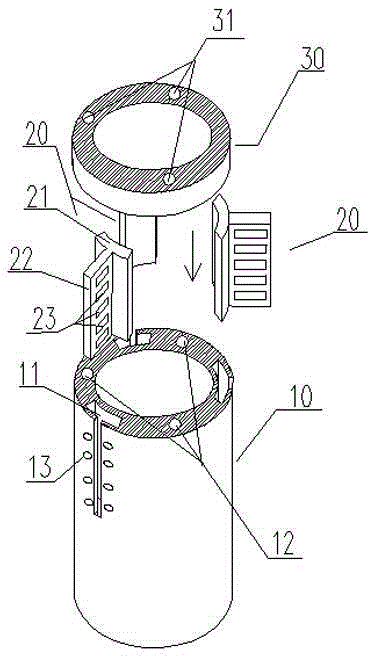

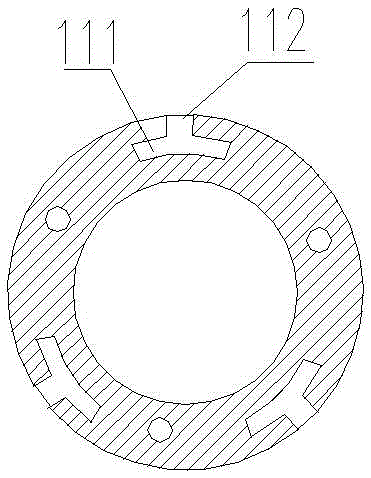

[0020] Embodiment 1 of the present invention is, as figure 1 Shown is the assembly drawing of the components of the finned muffler cooling device of the present invention, including the muffler cylinder, which is the shell of the resistive muffler in the prior art, and the sound-absorbing material of the muffler is set At the inner wall close to the side wall of the muffler cylinder, the side wall of the muffler cylinder 10 is provided with at least one cooling fin chute 11, and the cooling fin chute 11 is composed of the first cavity 111 and the second groove. cavity 112 constitutes,

[0021] The first groove 111 is inside the side wall of the muffler cylinder, the axial direction of the first groove is parallel to the axial direction of the muffler cylinder, and the cross ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com