Laser-cladding molten pool defocusing quantity measuring device and measuring method

A measurement device, laser cladding technology, applied in the direction of measurement devices, optical devices, instruments, etc., can solve the problems of high price of 3D shape sensor, unfavorable equipment cost control, inability to measure defocus in real time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The existing molten pool defocus measurement device for laser cladding has the following problems: it cannot measure the defocus in real time, and the volume increases, which is not conducive to the integration of equipment, and also increases the equipment cost.

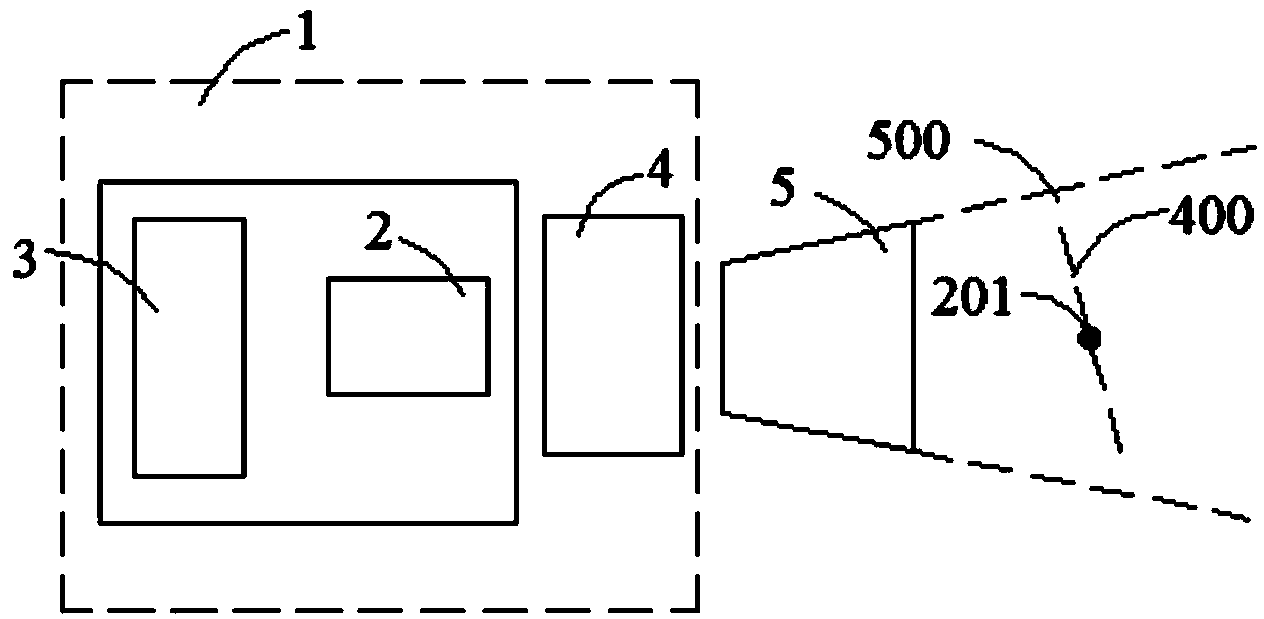

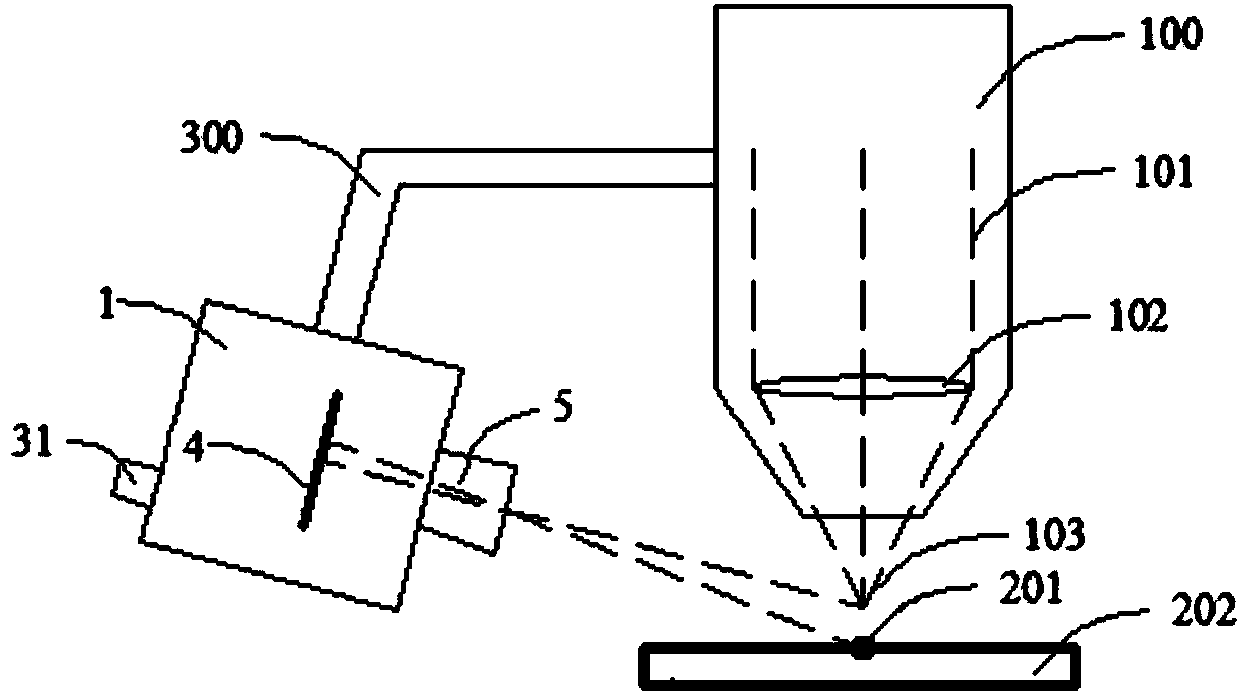

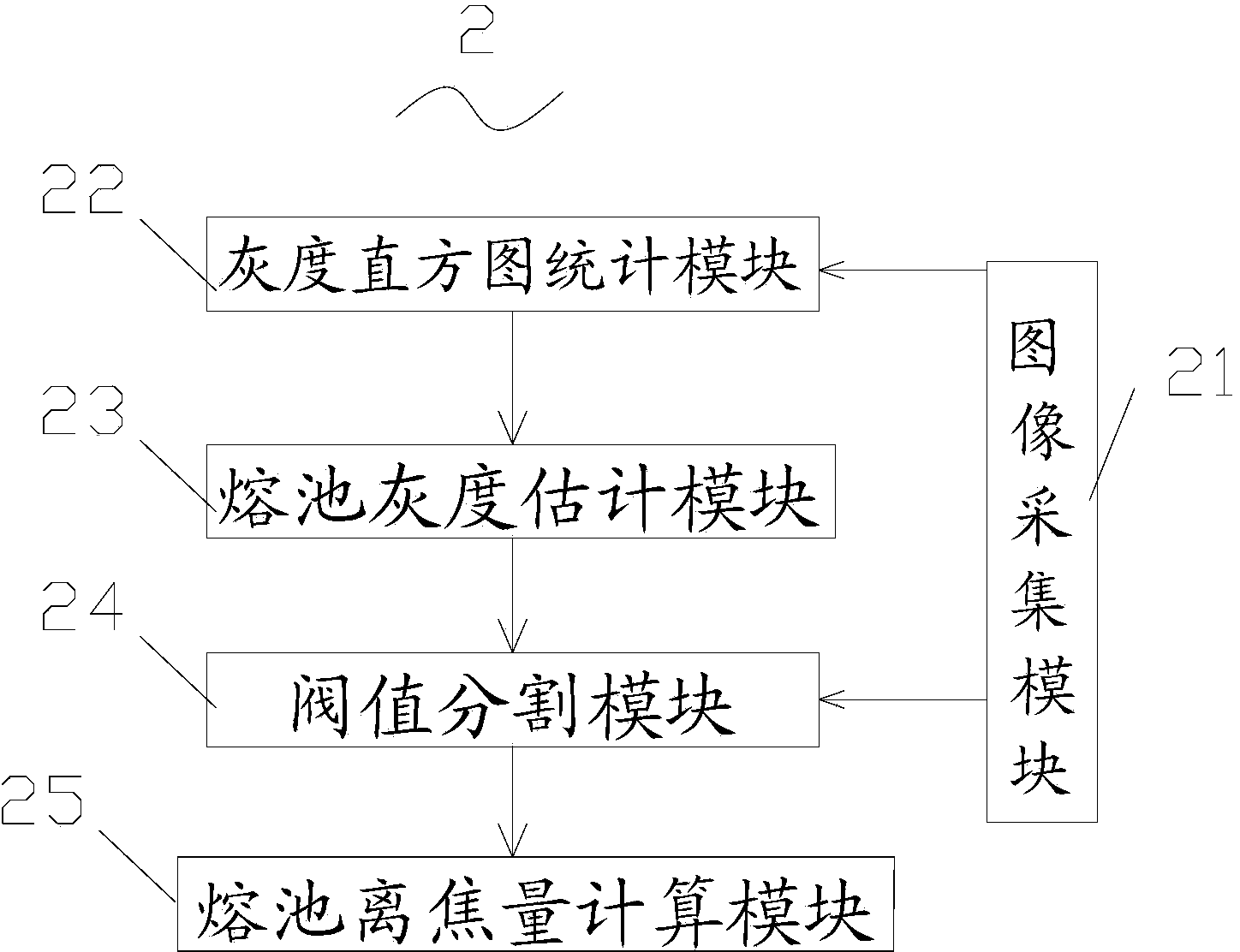

[0034] In view of the above-mentioned problems in the prior art, the present invention discloses a laser cladding melt pool defocus measurement device, including a housing, a lens, a CMOS image sensor, a controller and a communication module connected in sequence, the CMOS image Sensors, controllers, and communication modules are arranged in the housing, and the lens is fixed outside the housing and connected to the CMOS image sensor. The lens is used to collect the real image of the molten pool and project it onto the On the surface of the COMS image sensor, the COMS image sensor is used to convert the received optical real image into a digital image, and the controller analyzes the molten pool position accor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com