Paraxial tilting rotary table for linear three-coordinate transformation machine

A three-coordinate, linear technology, applied in the field of satellite assembly testing, can solve problems such as poor structural stability, low load capacity, and low inclination measurement accuracy, and achieve the effects of reducing measurement deviation, improving load capacity, and reducing invalid loads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

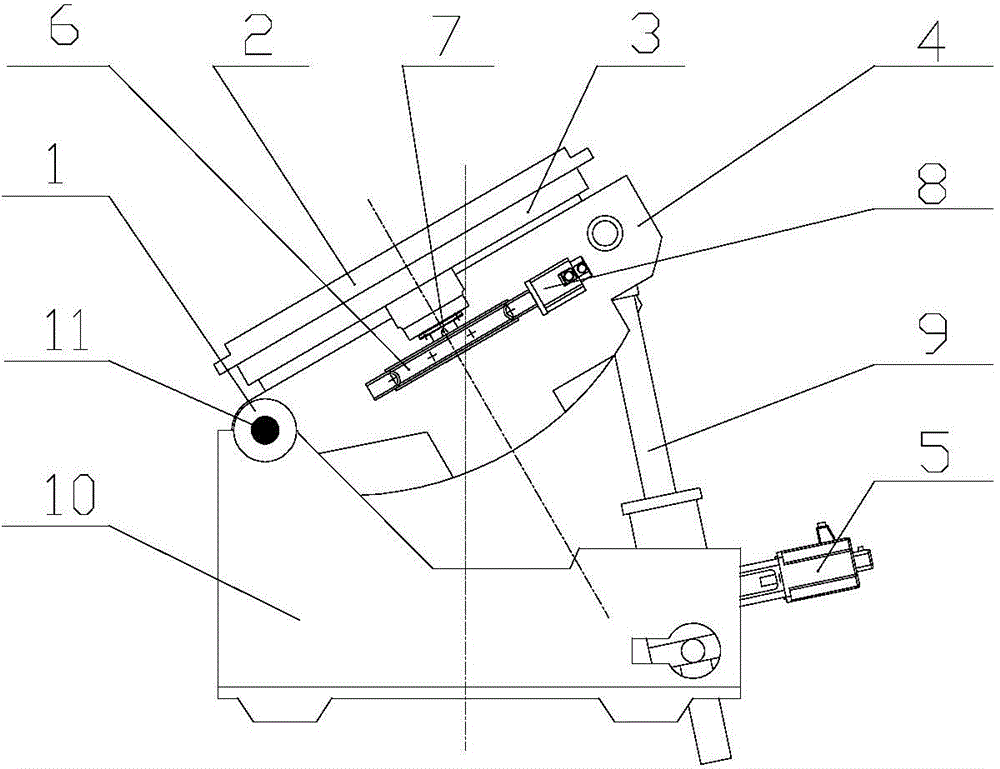

[0018] Such as figure 1 As shown, the device structure of the side-axis tilting turntable of the linear three-coordinate conversion machine of the present invention is shown. 3. Planar air bearing seat 4 with a cavity inside (for supporting the support seat of the plane air bearing lower plate), servo motor 2 5, worm gear assembly 6, circular grating encoder 2 7, servo motor 1 8, push rod Assembly 9, turntable base 10 and inclined support shaft 11 are formed. Wherein, the plane air-floating upper plate 2 is connected on the plane air-floating lower plate 3 by screws, the plane air-floating lower plate 3 is fixedly supported on the plane air-floating seat 4 which is hollow inside, and the worm gear assembly 6 is arranged in the hollow of the plane air-floating seat. Inside the cavity, the worm gear shaft in the worm gear assembly 6 passes through the plane air bearing lower plate 3 and is fixedly connected with the plane air bearing upper plate 2. Motor one 8 is connected to ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap