Pixel structure and manufacturing method and repair method thereof

A technology of pixel structure and manufacturing method, applied in nonlinear optics, instruments, optics, etc., can solve problems such as poor repair effect, long wiring lines, input signal delay distortion, etc., to achieve the effect of line defect repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

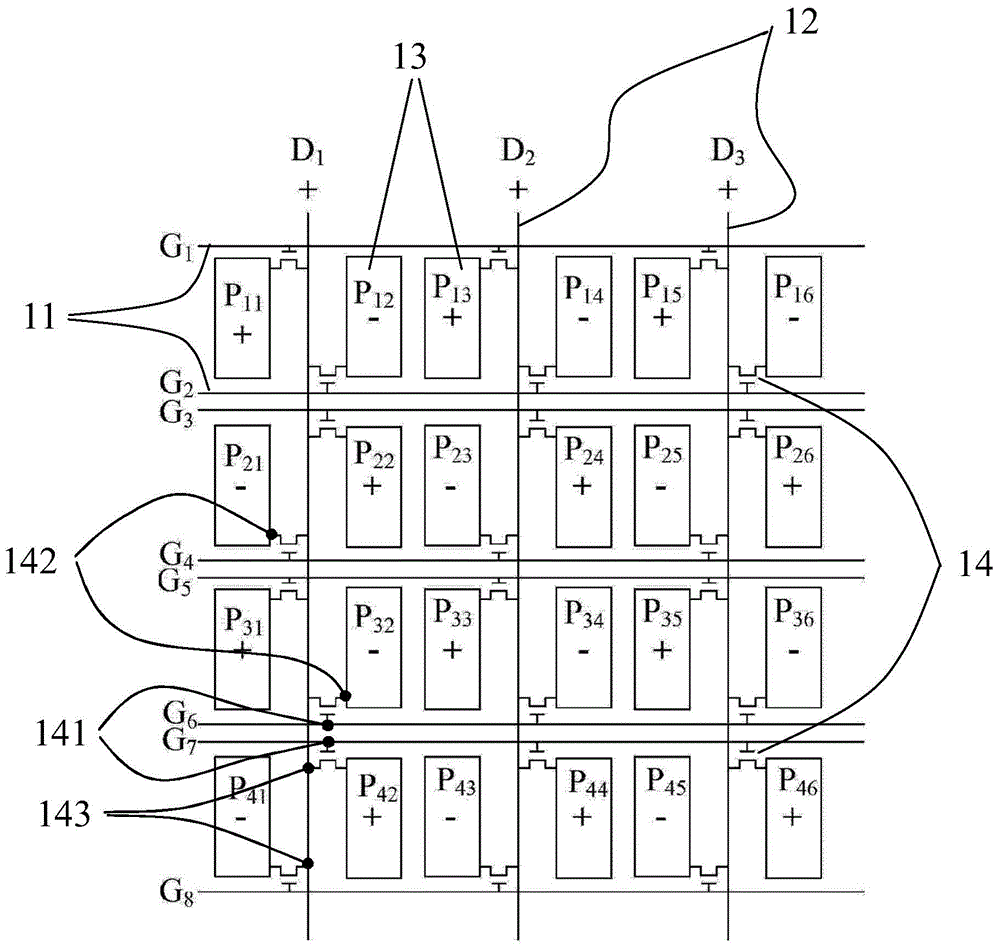

Embodiment 1

[0074] Figure 5 It is a schematic diagram of repairing a broken scanning line of a double-gate pixel structure including H-shaped repairing lines according to an embodiment of the present invention. Such as Figure 5 As shown, in the pixel structure driven by double gates, an H-shaped repair line structure is designed between the upper row of pixels and the lower row of pixels. The scan lines of a row of pixels overlap.

[0075] Such as Figure 5 With the pixel structure driven by double gates shown, when a breakpoint 53 occurs in the scan line 51, the corresponding repair method is as follows:

[0076] a. On the scan line 51 where the disconnection occurs, find the area where the H-shaped repair line 57 on the left and right sides of the breakpoint 53 overlaps with the scan line 51 .

[0077] b. Laser welding is performed on the overlapping areas on both sides of the break point respectively to form welding points 521 and 522 .

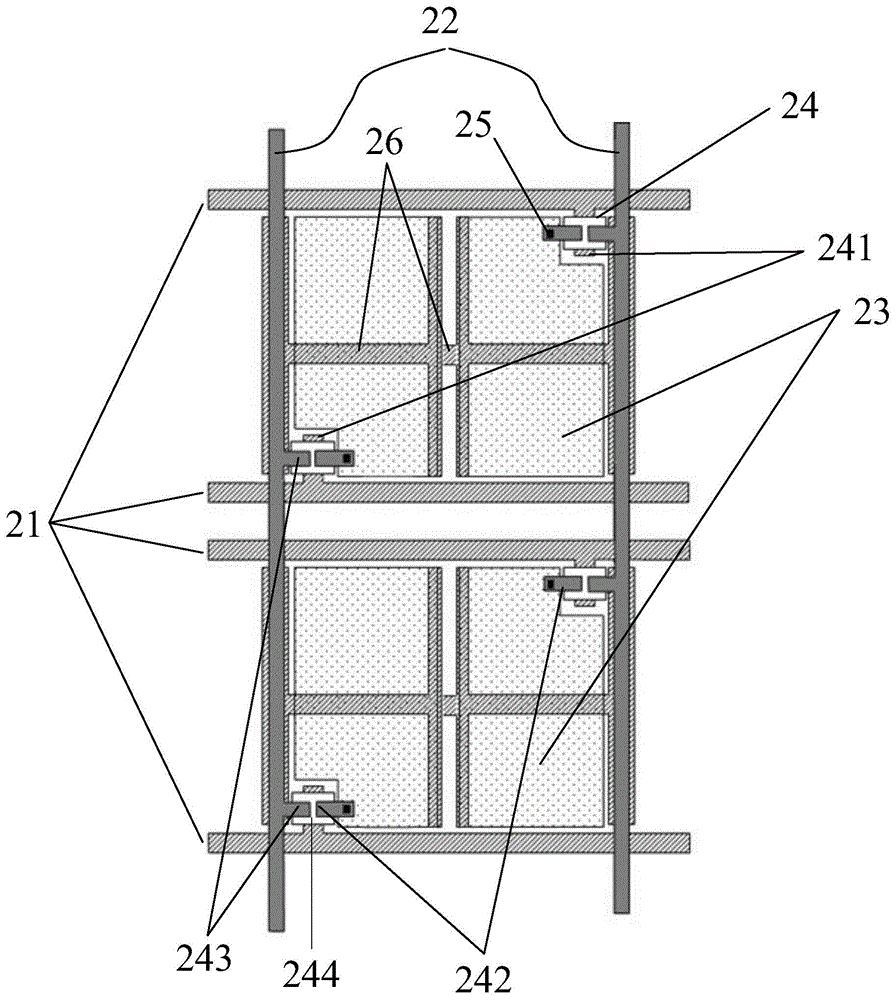

Embodiment 2

[0080] Image 6 It is a schematic diagram of repairing a broken scan line of a double-gate pixel structure including a "Feng"-shaped repair line according to an embodiment of the present invention. Such as Image 6 As shown, in the pixel structure driven by double gates, a "Feng" font is designed between the upper row of pixels and the lower row of pixels, and between the right pixel of the left data line and the left pixel of the right data line The repair line structure, the "Feng" font repair line structure is a simultaneous electrical connection of the upper and lower H-shaped repair line structures through the connection line between the right pixel of the left data line and the left pixel of the right data line. layer metal structure. In the H-shaped repair line structure in the "Feng"-shaped repair line structure, the bottom of both sides is designed with the same layer of repair liners as the scan line. Both ends of the repair liner have partial overlapping regions ...

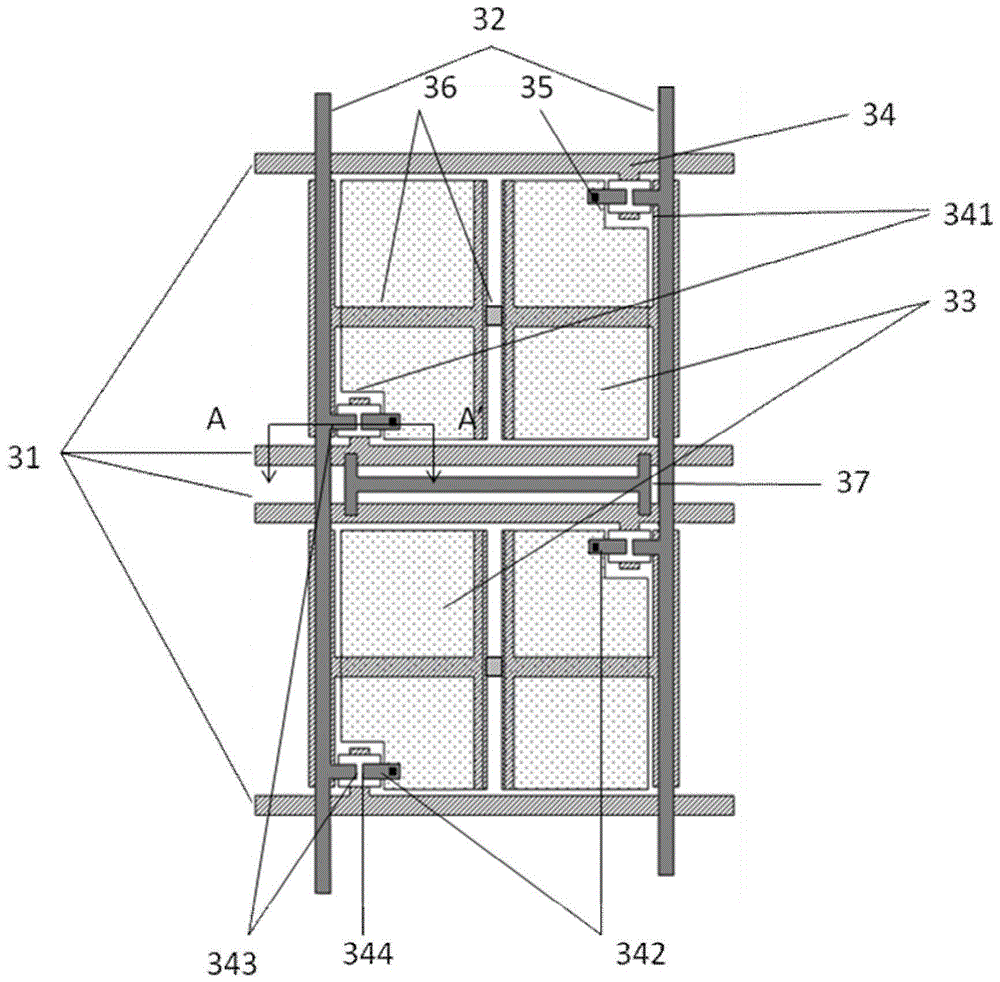

Embodiment 3

[0086] Figure 7 It is a schematic diagram of data line broken line repairing in a dual-gate pixel structure including "Feng"-shaped repairing lines according to an embodiment of the present invention. Such as Figure 7 As shown, in the pixel structure driven by double gates, a "Feng" font is designed between the upper row of pixels and the lower row of pixels, and between the right pixel of the left data line and the left pixel of the right data line The repair line structure, the "Feng" font repair line structure is a simultaneous electrical connection of the upper and lower H-shaped repair line structures through the connection line between the right pixel of the left data line and the left pixel of the right data line. layer metal structure. In the H-shaped repair line structure in the "Feng"-shaped repair line structure, the bottom of both sides is designed with the same layer of repair liners as the scan line. Both ends of the repair liner have partial overlapping reg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com