Cathode protective potential monitoring system for buried metal pipeline

A cathodic protection and potential monitoring technology, applied in the direction of electrical signal transmission system, signal transmission system, measuring device, etc., can solve the problem that the method of collecting cathodic protection data has not been improved, and it is difficult to meet the needs of real-time detection of pipeline cathodic protection, etc. Achieve the effects of saving labor costs, satisfying real-time detection, and improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

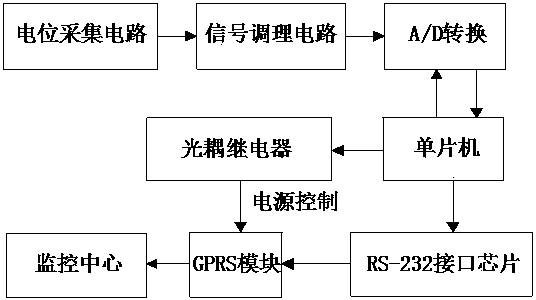

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings.

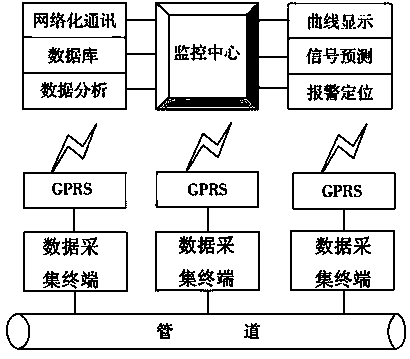

[0020] figure 1 It is the overall principle block diagram of the cathodic protection potential monitoring system for buried metal pipelines. The system includes a monitoring center and a number of data acquisition terminals. Several data acquisition terminals are distributed in different measurement positions of the tested pipeline 3, and are used to measure the potential of different positions on the tested pipeline 3. The monitoring center is used to receive various data. The detection data fed back by the terminal is collected, and the detection data is stored in the database for real-time data display and historical data callback. At the same time, it is supplemented by the data analysis function of the monitoring center to realize the functions of signal prediction and alarm and pipeline abnormal point positioning.

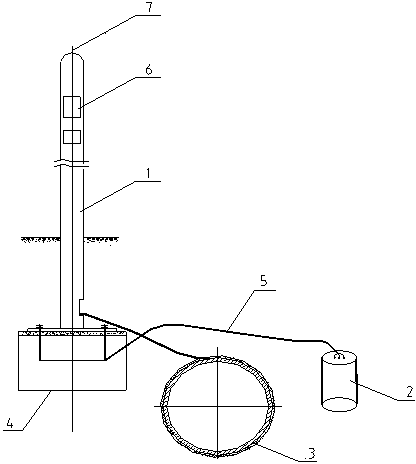

[0021] figure 2 is the structure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com