Yarn storage device for a textile machine

A yarn storage and equipment technology, which is applied in the fields of replenishing the yarn source of yarn processing machines, yarn processing machines, and looms, can solve the problems of machines not being able to produce, manually repairing broken ends of silk threads, and taking too long to maintain shape and Stability, effect of reducing the risk of tangling and knotting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

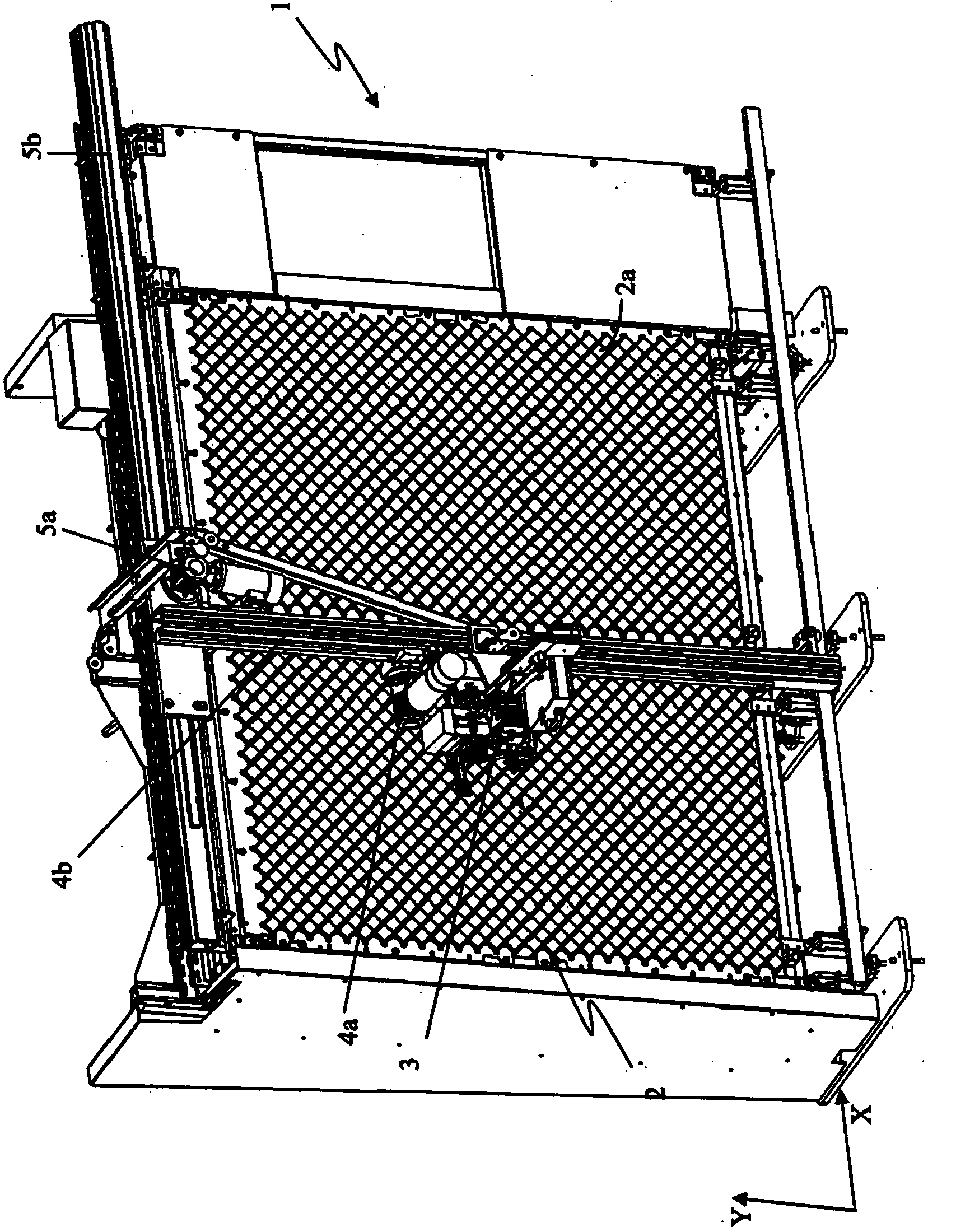

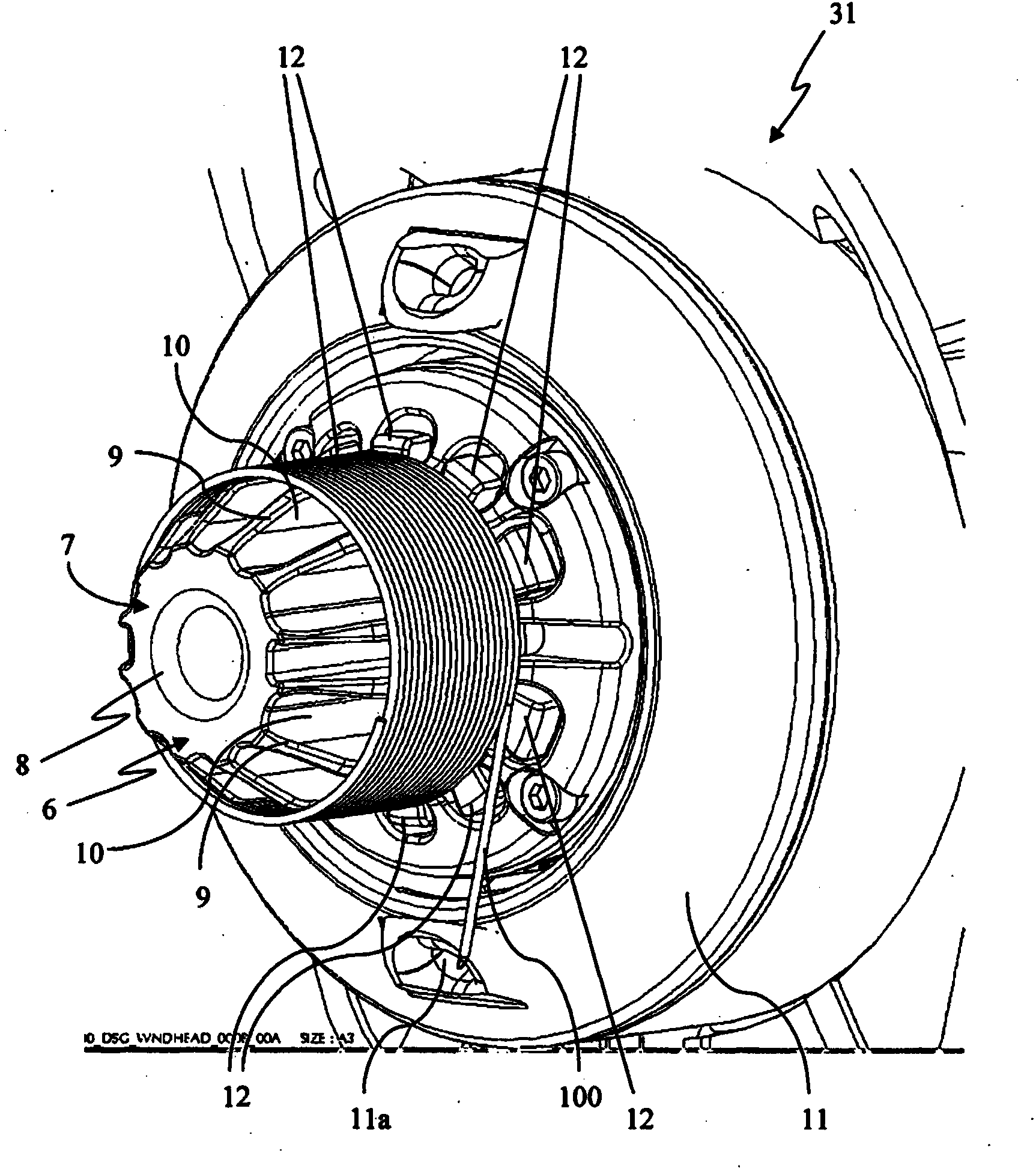

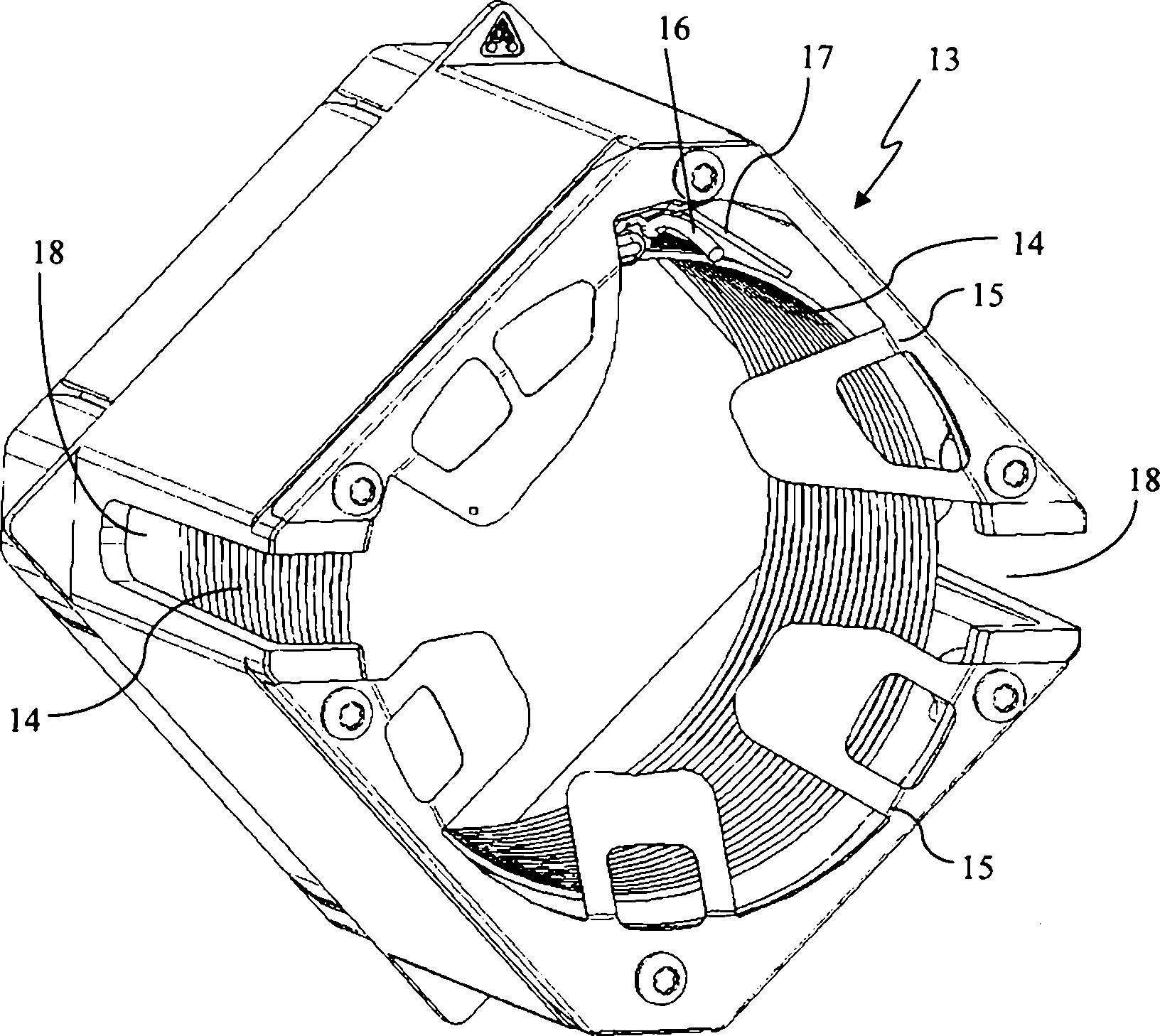

[0103] The yarn storage device shown in the figure is used to supply different yarns to yarn processing units such as looms. The device is particularly suitable for storing different yarns used in different quantities in a yarn processing unit. For example, the yarn provided in the yarn storage device is pile yarn of a loom for weaving pile fabrics.

[0104] There are external sources of yarn for various types or colors of yarn, for example in the form of one or more dyed bobbins containing a large number of said yarns. Different yarns (yarn types and / or yarn colors) are introduced into a number of yarn supply channels by means of one or more movable yarn loaders. Depending on the consumption of the yarn, the yarn in these yarn supply channels is automatically replenished.

[0105] Optionally, means may be provided for automatically replacing a particular external yarn source with another external yarn source of a different type and / or colour. These devices then comprise cu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com