Automatic fertilizing machine

A fertilizer machine and automatic technology, applied in the field of automatic fertilizer machine, can solve the problems of abandonment of packaging bags, failure of liquid fertilizer function, direct contact with children, etc., so as to reduce the process of opening packaging, improve mass production, and reduce storage inconvenience. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

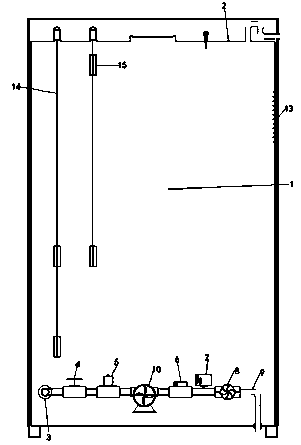

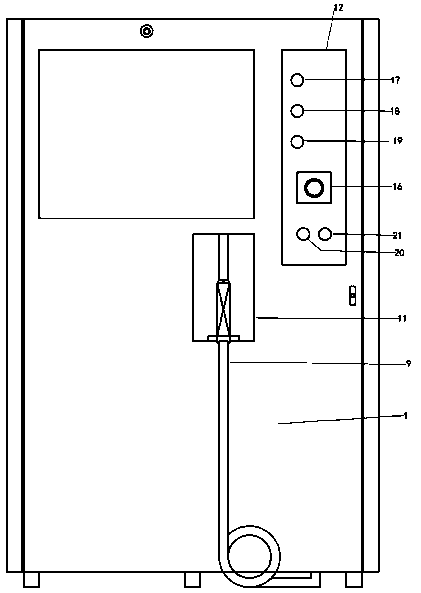

[0013] An automatic fattening machine, characterized in that: the liquid storage tank (1) is provided with a liquid storage tank (2), a liquid outlet device (3), a liquid outlet valve (4), a solenoid valve (5), and a check valve (6), pressure switch (7), turbine flowmeter (8), liquid outlet pipe (9), booster pump (10), liquid filling gun (11), display (12); the liquid storage tank (2) passes The liquid outlet device (3) is connected to the liquid outlet valve (4), the solenoid valve (5) is connected to the liquid outlet valve (4), the booster pump (10), the check valve (6) is connected to the booster pump (10), and the pressure switch (7), the turbine flowmeter (8) is connected to the pressure switch (7), the liquid outlet pipe (9), and the liquid outlet pipe (9) is connected to the liquid filling gun (11).

[0014] The liquid storage tank (1) is equipped with an insulation layer and an electric heating device (13) outside, and the liquid storage tank (2) is provided with a st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com