The structure of the pressure cylinder driving the double-ended collet in the main shaft

A pressure cylinder and spindle technology, which is applied in the field of machine tools, can solve the problems of large axial size of the spindle, laborious tightening methods, and increased manufacturing costs, and achieve the effects of increasing the range of workpieces to be processed, firm locking, and improving machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

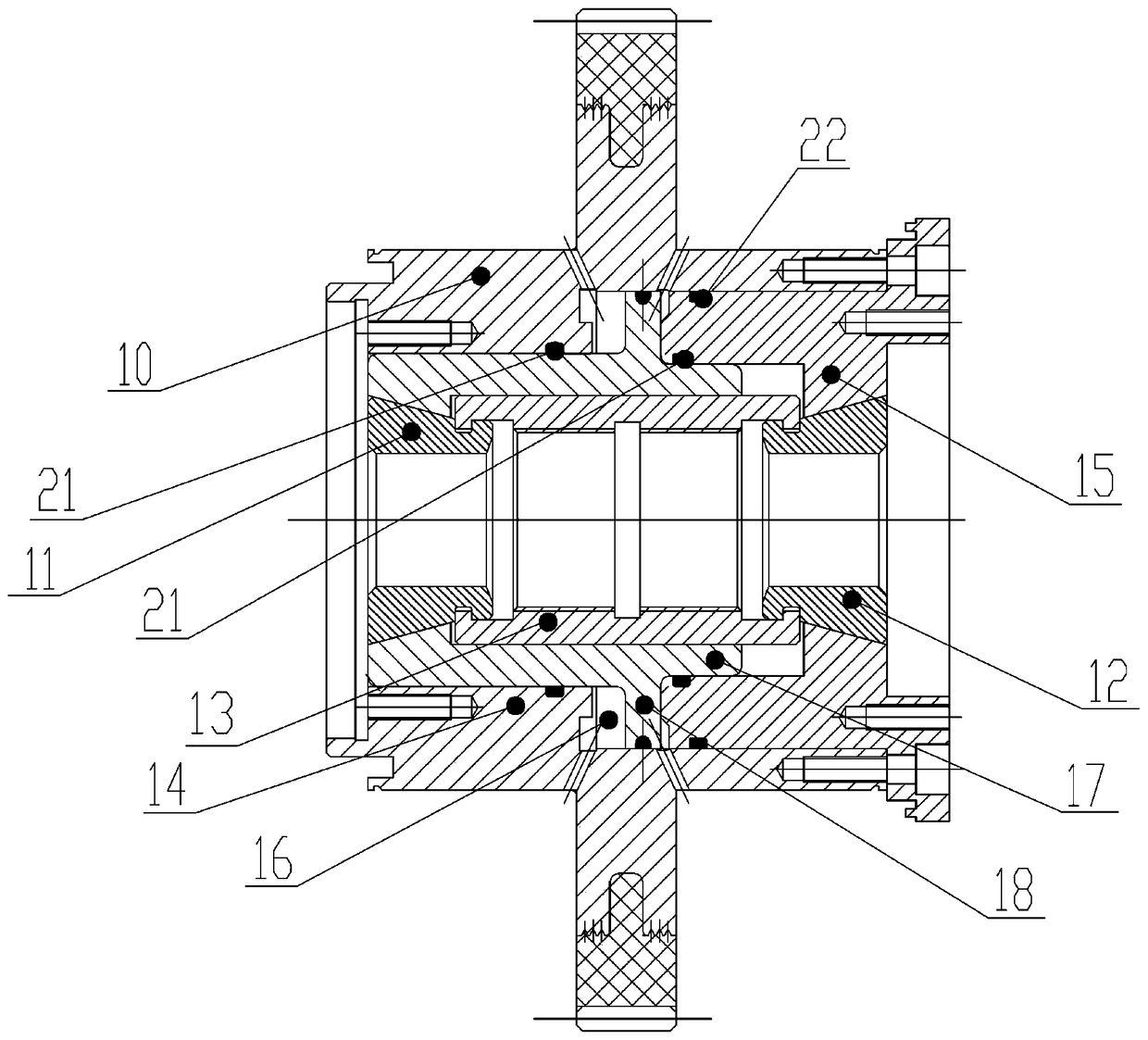

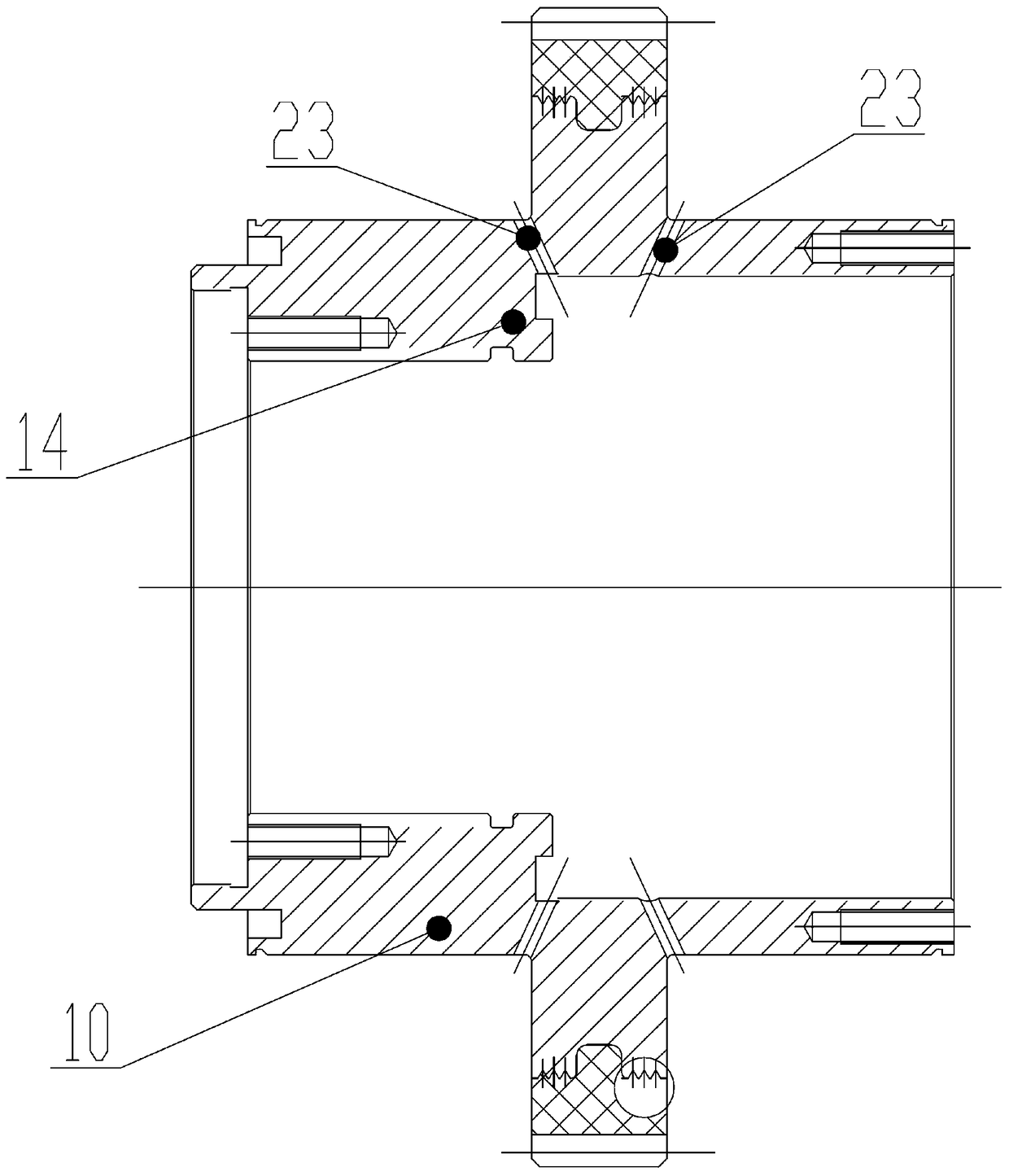

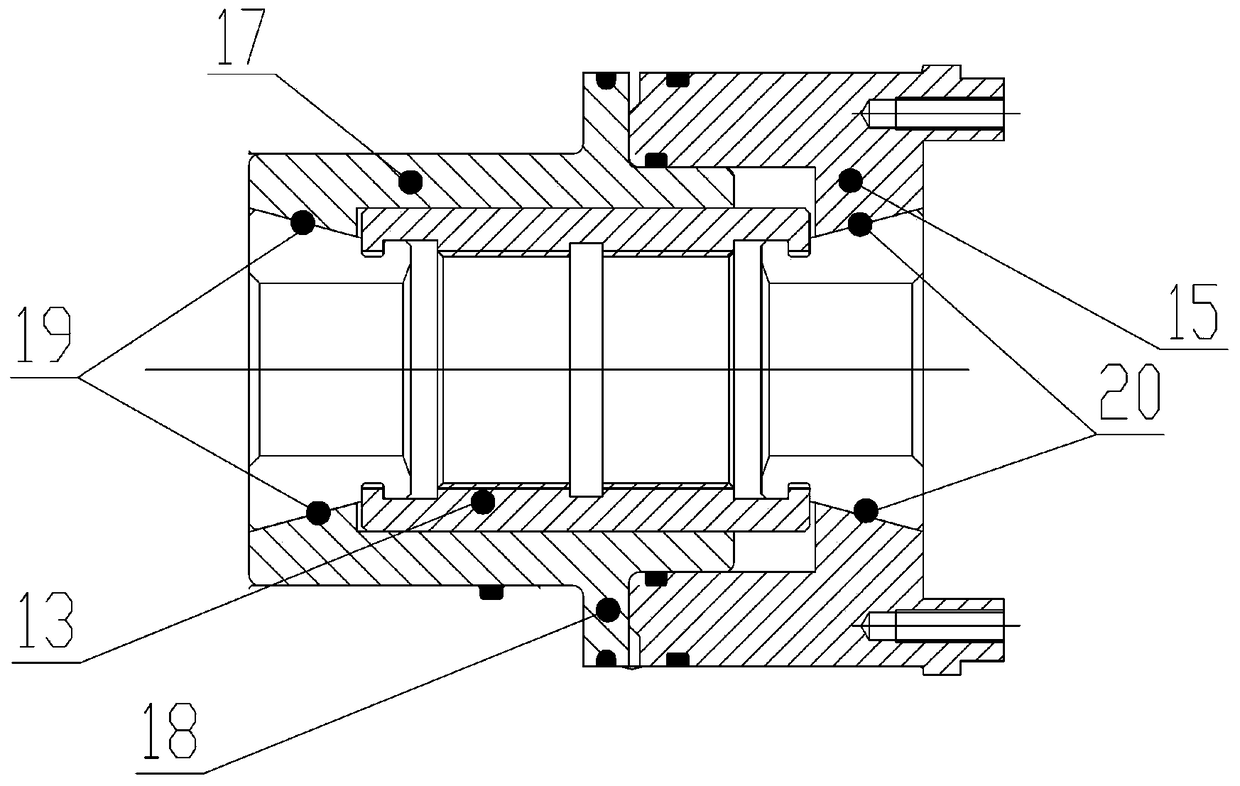

[0016] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see figure 1 —3: The pressure cylinder structure driving the double-head collet in the main shaft, including the main shaft 10 and the collet I11 and the collet II12 arranged between the inner wall of the main shaft 10 and the drawing tube, and the collet I11 and the collet II12 are clamped on The two ends of the pull tube 13, wherein, the inner wall of one end of the main shaft 10 is provided with a limit ring 14, the limit ring 14 is located at the same end of the main shaft 10 as the collet I11, the limit ring 14 is raised, and its aperture is smaller than The aperture of the main shaft 10 is stepped, and the inner wall of the other end is provided with a cylinder cover 15, and the cylinder cover 15 is inserted into the hole of the main shaft 10, and a piston assembly is arranged between the limit ring 14 and the cylinder cover 15. The combined sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com