Conductive cloth adhesive tape and production technique thereof

A production process and technology of conductive cloth, applied in the field of conductive cloth tape and its production process, can solve the problems of high rejection rate and labor consumption, and achieve the effect of saving enterprise cost and manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

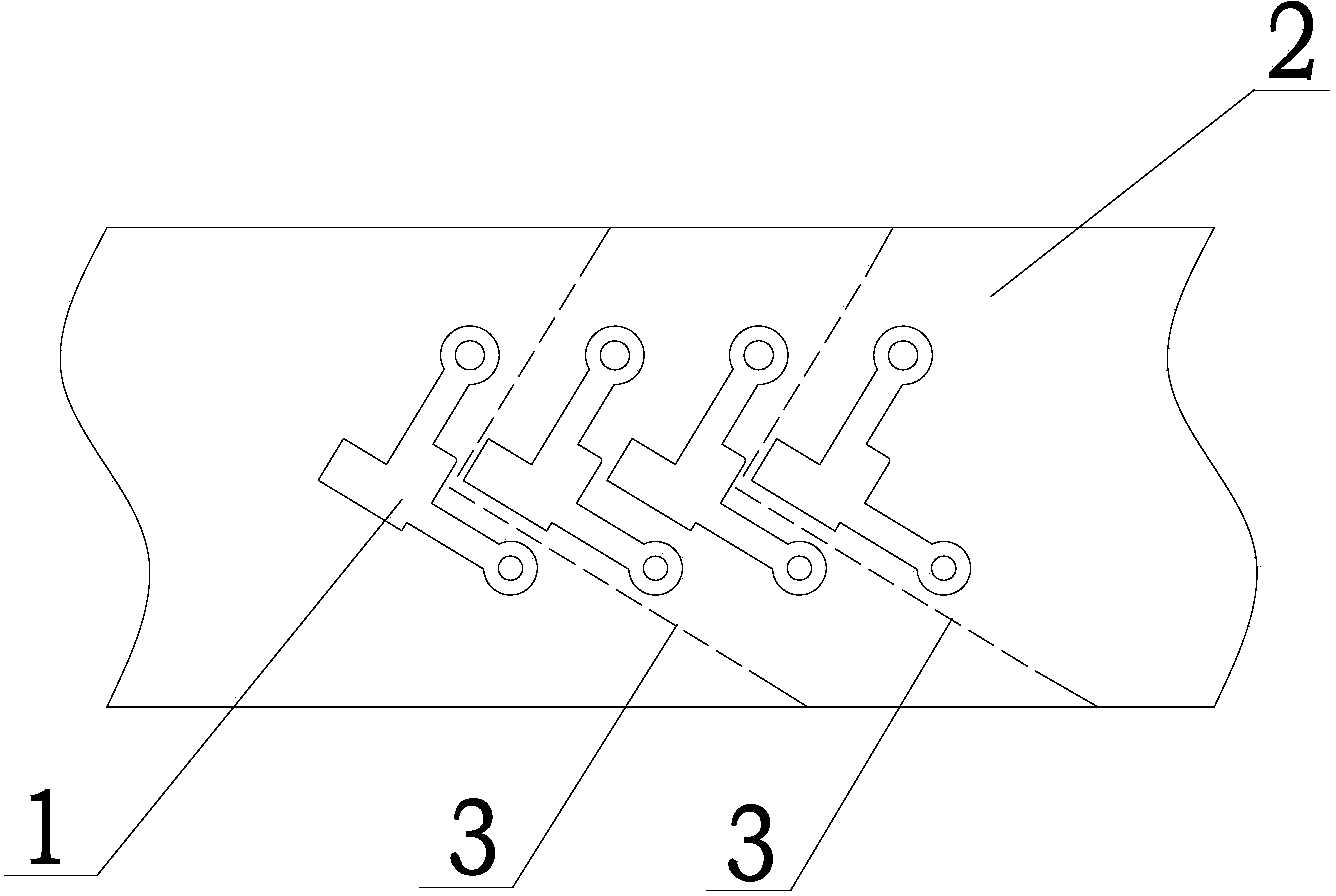

[0020] see figure 1 As shown, a conductive cloth tape includes a conductive cloth layer, an adhesive layer pasted on one side of the conductive cloth layer, and a release layer 2 covering the adhesive layer. Cloth unit 1, the release layer 2 is provided with a tooth line 3 that can be torn along its own length direction, the tooth line 3 is spaced apart on the release layer 2 along its own length direction, and the tooth line 3 can be completely separated Two adjacent conductive cloth units 1 .

[0021] One or more conductive cloth units 1 can be surrounded between the two tooth lines 3 as required.

[0022] Above-mentioned conductive cloth adhesive tape can be produced with following production process, comprises the following steps:

[0023] (1) Material preparation: prepare the conductive cloth tape required for the process, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com