Crucible

A crucible and sub-cavity technology, applied in the field of evaporation, can solve problems such as drifting, material leakage, and cost increase, and achieve the effects of avoiding leakage, uniform quality, and convenient cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

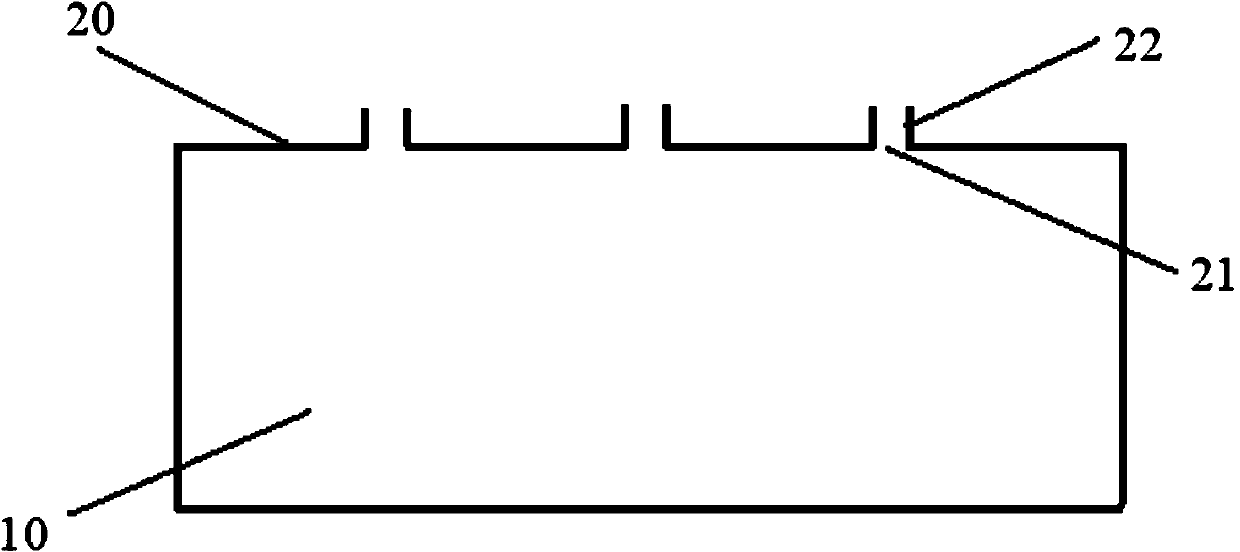

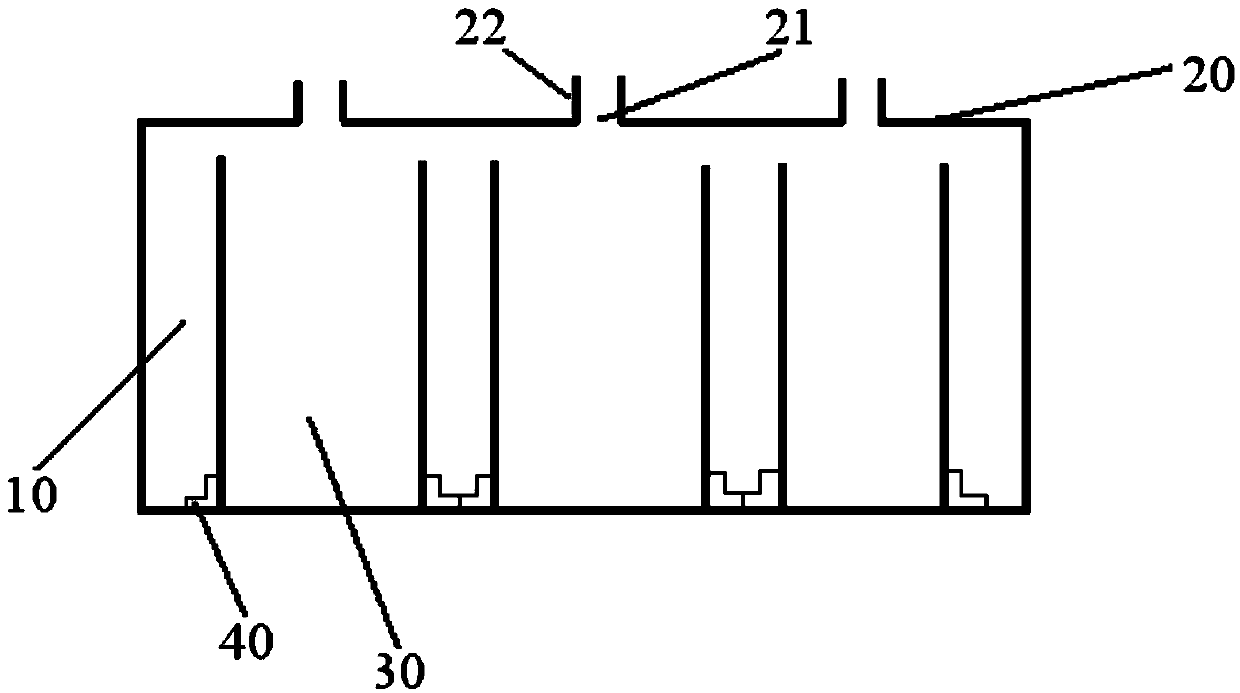

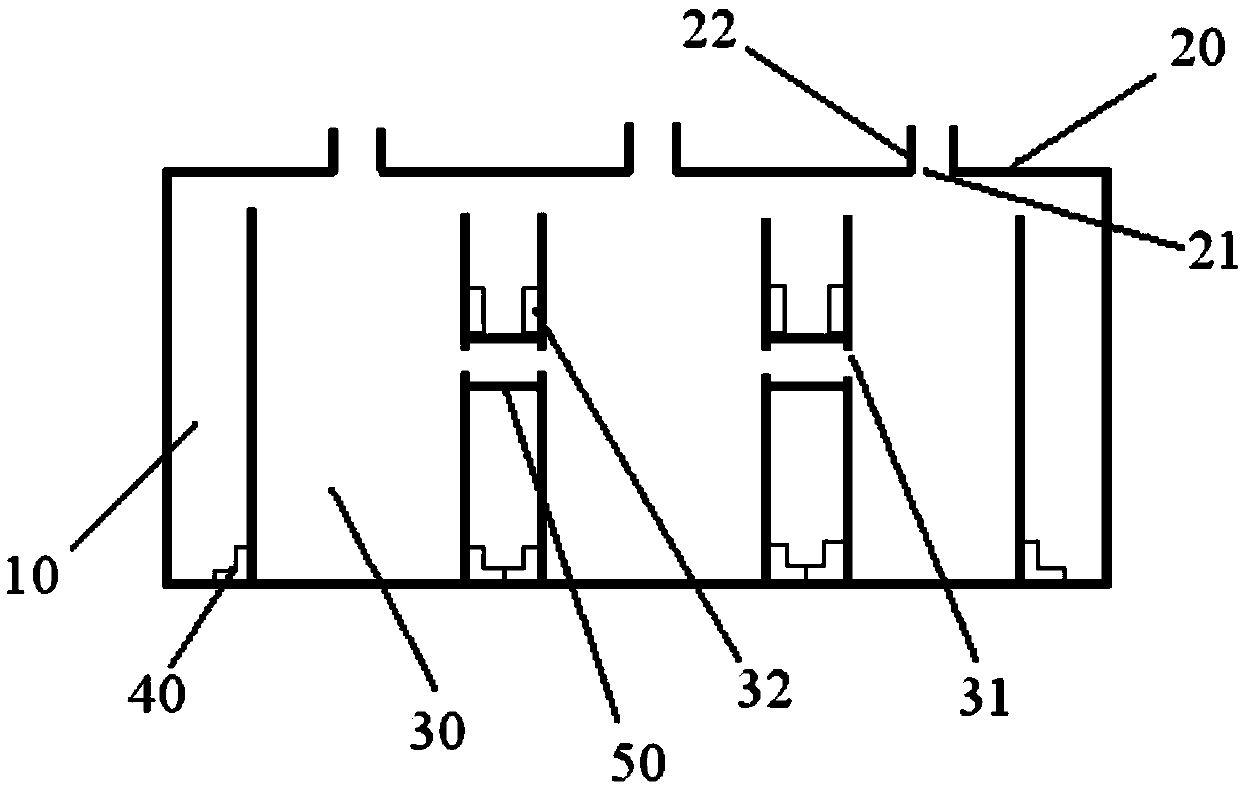

[0023] combine figure 2 , 3 As shown in , 4, this embodiment provides a crucible, which includes a crucible main cavity 10, and a plurality of crucible sub-cavities 30 arranged in the crucible main cavity 10 for containing evaporation materials.

[0024] The crucible in this embodiment includes several crucible sub-cavities 30. Since the volume of the crucible sub-cavities 30 is relatively small relative to the crucible main cavity 10, when the crucible sub-cavities 10 are used to hold evaporation materials, the operator will There is no need to move and fill the vapor deposition material, thereby avoiding leakage, drift and loss of the vapor deposition material; meanwhile, the volume of the crucible sub-cavity 30 is small, so the mass of the vapor deposition material loaded can be weighed more accurately by using a balance, In order to ensure that the quality of the evaporation material loaded into the crucible sub-cavity 30 is more uniform; of course, because the volume of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com