Fully automatic test machine for severity level impact capacity of fire electronic product

A technology with severe grades and electronic products, which is applied in the field of full-automatic testing machines for grade impact capability, can solve problems that affect the quality of detection and reduce detection efficiency, and achieve the effect of eliminating human interference factors, improving detection quality and efficiency, and realizing detection automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

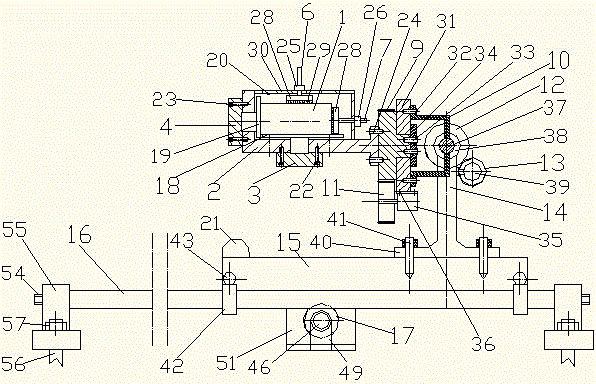

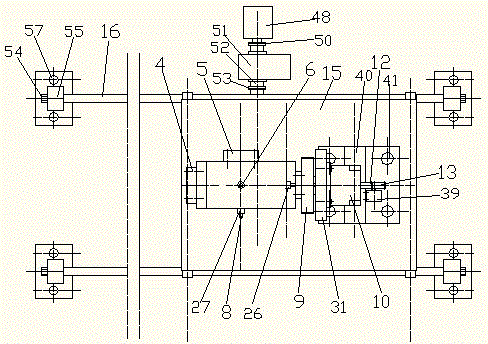

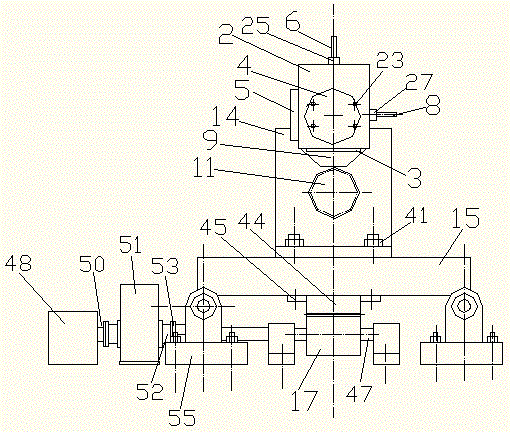

[0024] Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment includes a product sample 1, the product sample 1 is placed in the rotating bracket 2, and the lower side, the left side and the front side of the rotating bracket 2 are respectively fixed with a first pressure sensor 3, a second pressure sensor 4 and a third pressure sensor. The sensor 5, the upper side, the right side and the rear side of the product sample 1 are respectively provided with a first screw mandrel 6, a second screw mandrel 7 and a third screw mandrel 8, and the right end of the rotating bracket 2 is fixed on the first driven gear 9, The first driven gear 9 is fixed on the swing frame 10, the lower end of the first driven gear 9 is meshed with the first driving gear 11, the swing frame 10 is equipped with the second driven gear 12, and the second driven gear 12 is meshed with the second driving gear 13 , swing frame 10 is installed on the support column 14, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com