Dual-frequency band antenna structure and manufacturing method thereof

A technology of an antenna structure and a manufacturing method, which is applied in the field of dual-band antenna structure and its manufacturing, can solve the problems of antenna characteristic distortion of dual-band antenna, and achieve the effect of low axial ratio and high gain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example 〕

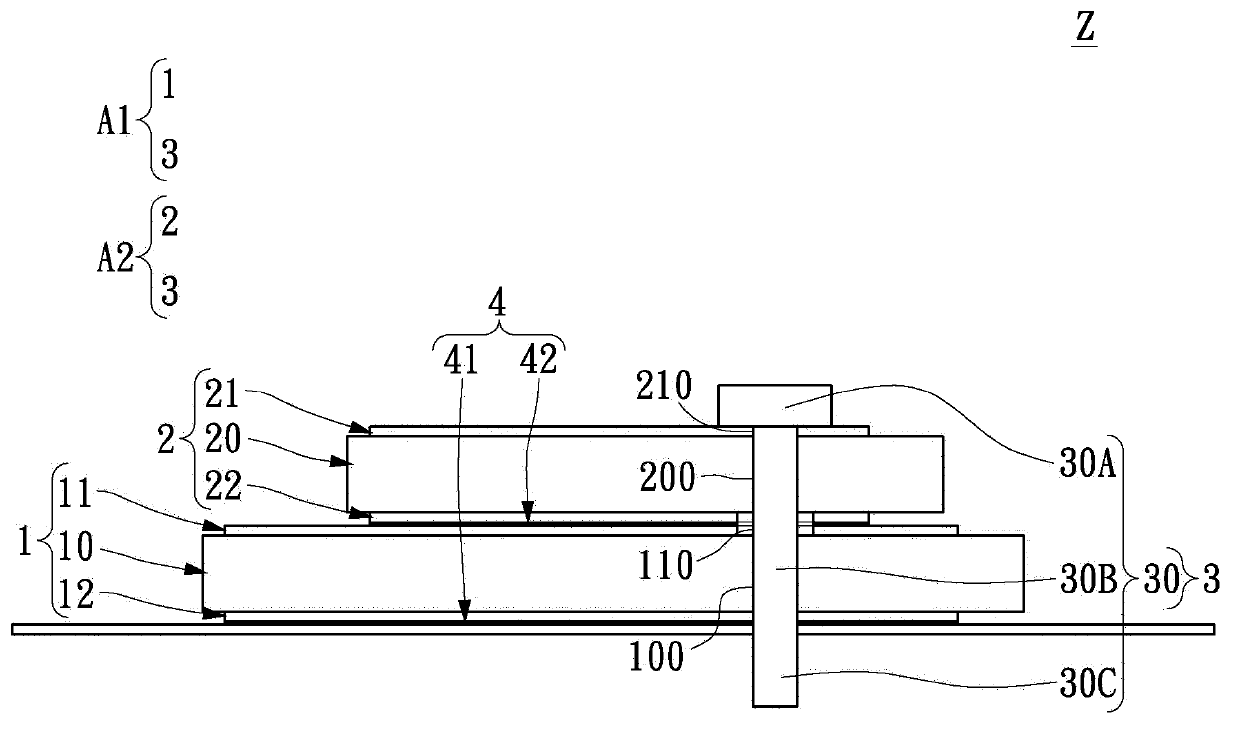

[0047] see figure 1 As shown, the first embodiment of the present invention provides a dual-band antenna structure Z, which includes: a first substrate unit 1 , a second substrate unit 2 and a pin unit 3 . In the first embodiment, at least one feed pin 30 passes through the first electrode through hole 110 and is insulated from the first electrode layer 11 , and the feed pin 30 passes through the second electrode through hole 210 and contacts the second electrode layer 21 , and the first set working frequency band of the first antenna A1 is greater than the second set working frequency band of the second antenna A2. Furthermore, when the first set working frequency band of the first antenna A1 is greater than the second set working frequency band of the second antenna A2, the feeding pin 30 passes through the first electrode through hole 110 and connects with the first electrode layer 11 They are insulated from each other, and the feeding pins 30 pass through the second elect...

no. 2 example

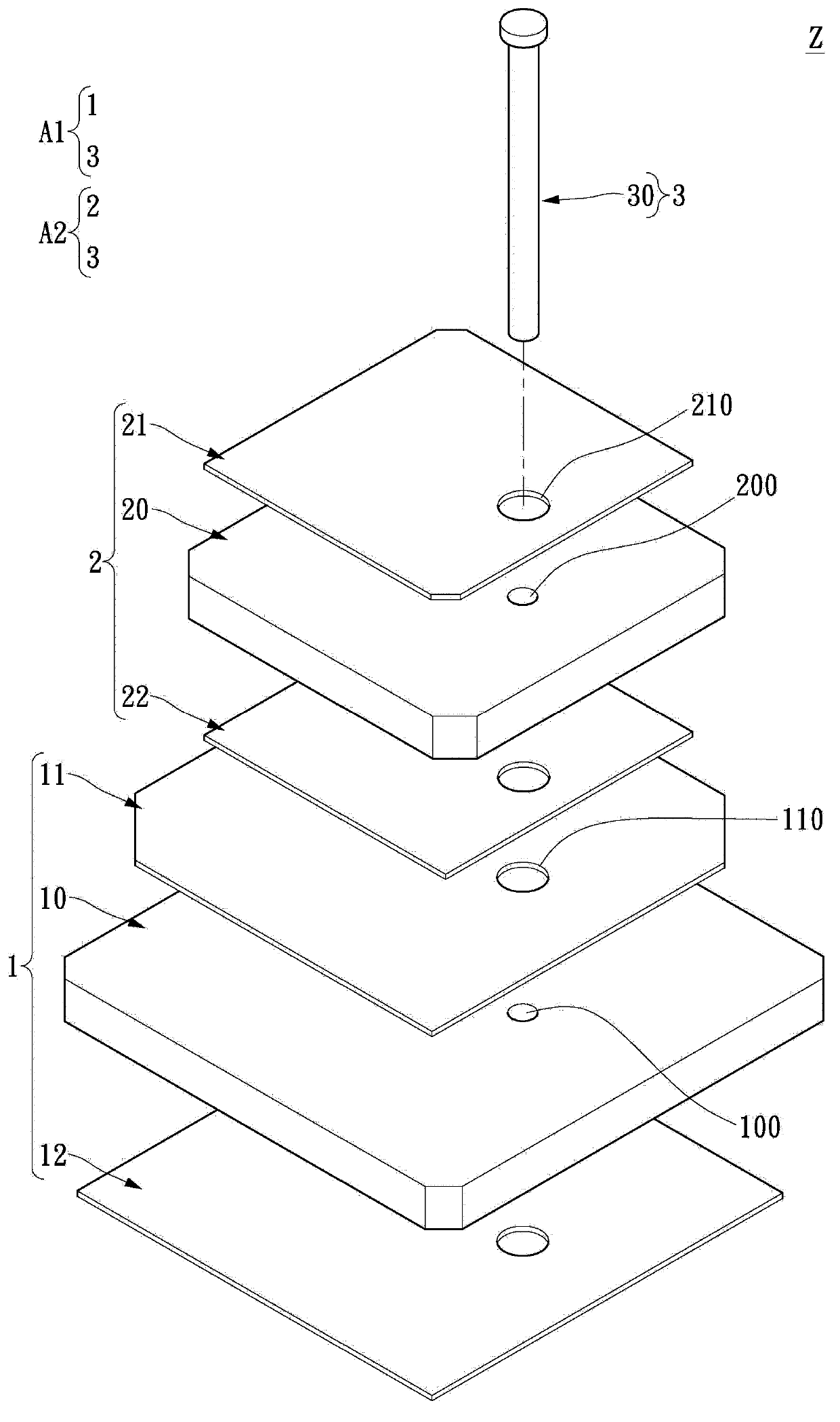

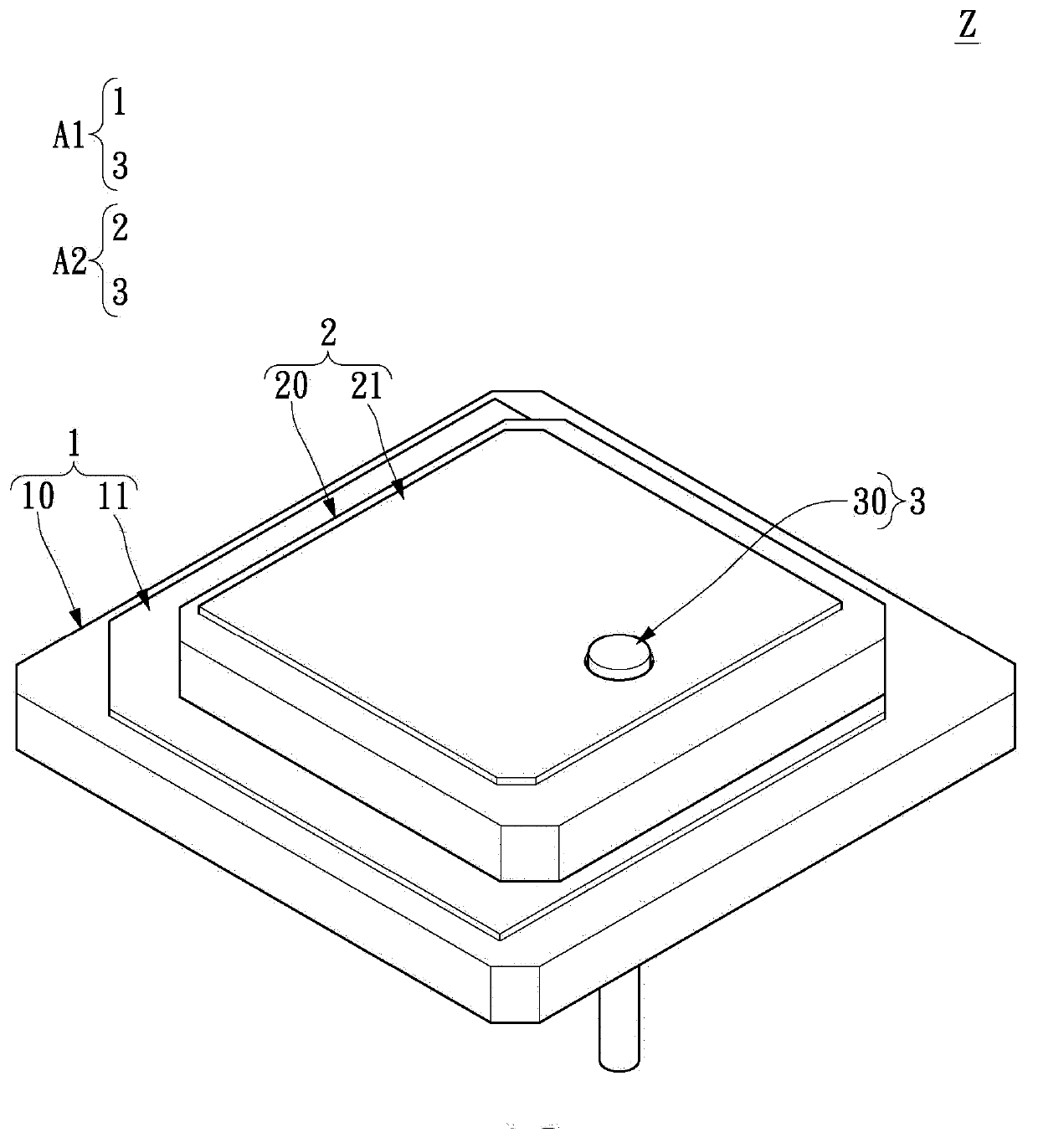

[0049] see Figure 2 to Figure 5 As shown, the second embodiment of the present invention provides a dual-band antenna structure Z, which includes: a first substrate unit 1 , a second substrate unit 2 and a pin unit 3 .

[0050] First, the first substrate unit 1 includes a first insulating substrate 10 and a first electrode layer 11 disposed on the top of the first insulating substrate 10, wherein the bottom of the first insulating substrate 10 has a first ground layer 12, The first insulating substrate 10 has a first through-substrate hole 100 , and the first electrode layer 11 has a first electrode through-substrate hole 110 corresponding to the first through-substrate hole 100 and larger than the first through-substrate hole 100 . In addition, the first insulating substrate 10 has a first dielectric constant. For example, the first insulating substrate 10 can be a ceramic substrate, and the first electrode layer 11 can be a conductive layer made of any conductive material....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com