Modular charging system for electrically operated power supplies

A technology of electric power operation power supply and charging system, which is applied to battery circuit devices, current collectors, electric vehicles, etc., can solve problems such as system collapse, system instability, high failure risk, etc., and achieve the effect of strong engineering practicability and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

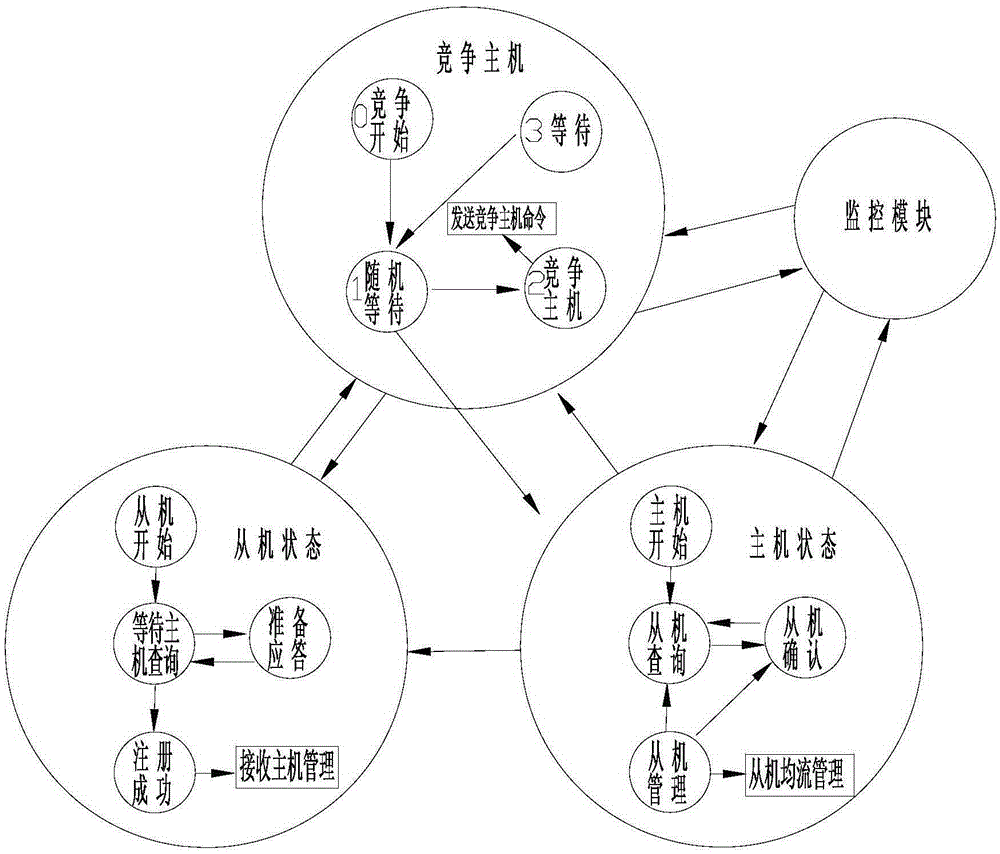

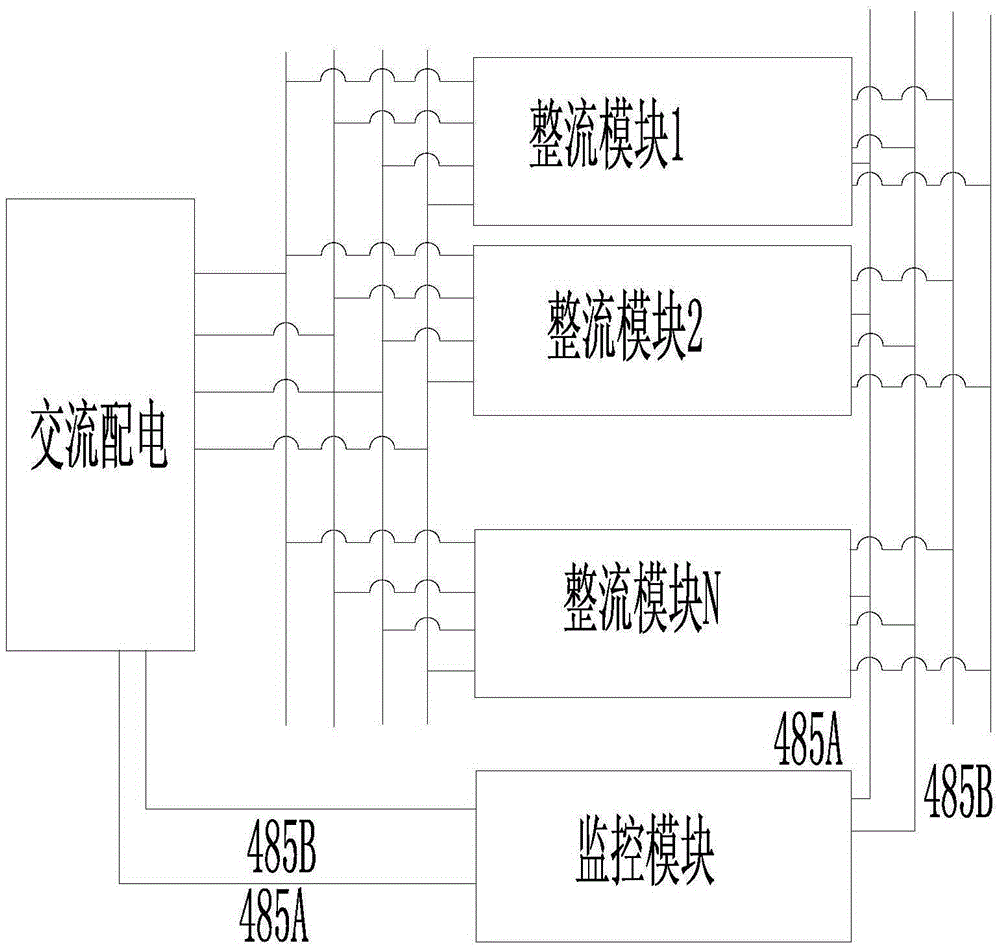

[0022] Modular charging system for electrically operated power sources such as Figure 1 to Figure 2 As shown, it includes the AC power distribution module connected to the three-phase AC, the rectification module that converts the AC output from the AC power distribution module into DC, and the monitoring module that outputs the voltage and current required by the load according to the charging information of the load. There is only one monitoring module mentioned above, and two or more rectifying modules are connected in parallel. Each rectifying module and monitoring module are connected through the RS485 bus. During each current sharing process in the system, the internal controller of each rectifying module performs the following judgment steps:

[0023] Step 1. Detect whether the communication with the monitoring module is normal, and if normal, turn to step 5;

[0024] Step 2. Generate random time according to the machine number of the rectifier module, and compete for ...

Embodiment 2

[0031] A modular charging system for electric operation power supply, including an AC power distribution module connected with three-phase AC, a rectification module that converts the AC output from the AC power distribution module into DC, and outputs the voltage required by the load according to the charging information of the load and current monitoring module. The monitoring module is responsible for managing the rectification module, and there may be multiple rectification modules. The existing RS485-based current sharing technology uses a monitoring module to receive the load current value of other rectification modules, and calculates the load current value after current sharing, and then sends it to each rectification module through the RS485 bus, and each rectification module Actively adjust its own output current to achieve system current sharing. If the monitoring module fails, the entire system current sharing will collapse.

[0032] The present invention is under...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com