Multiple coating device for strip substrates and strip substrate vacuum coating apparatus

A multi-layer coating and substrate technology, applied in coating, vacuum evaporation plating, metal material coating process, etc., can solve the problems of expensive structure, unable to replace the reel, cumbersome and other problems, and achieve the effect of keeping the structure simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

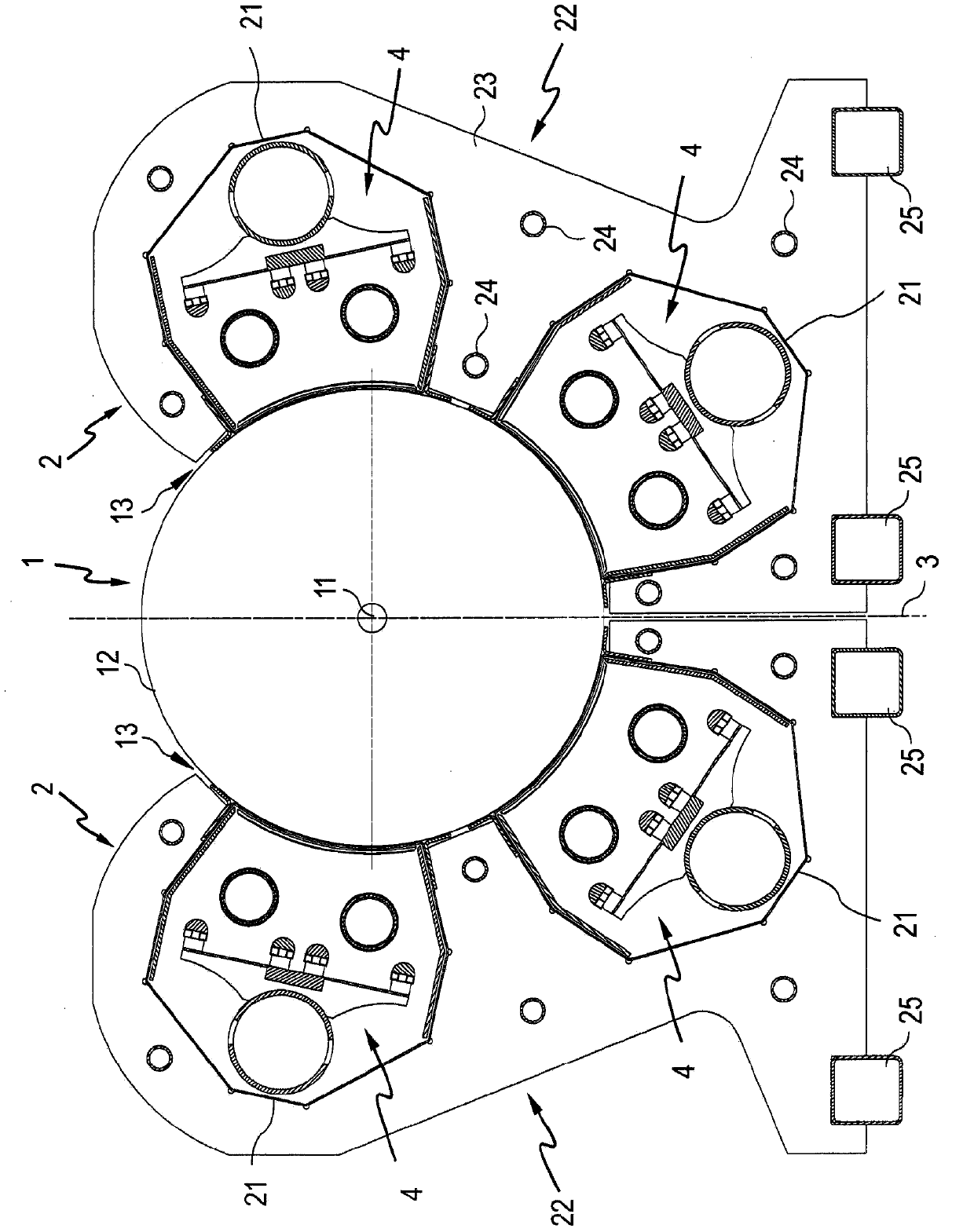

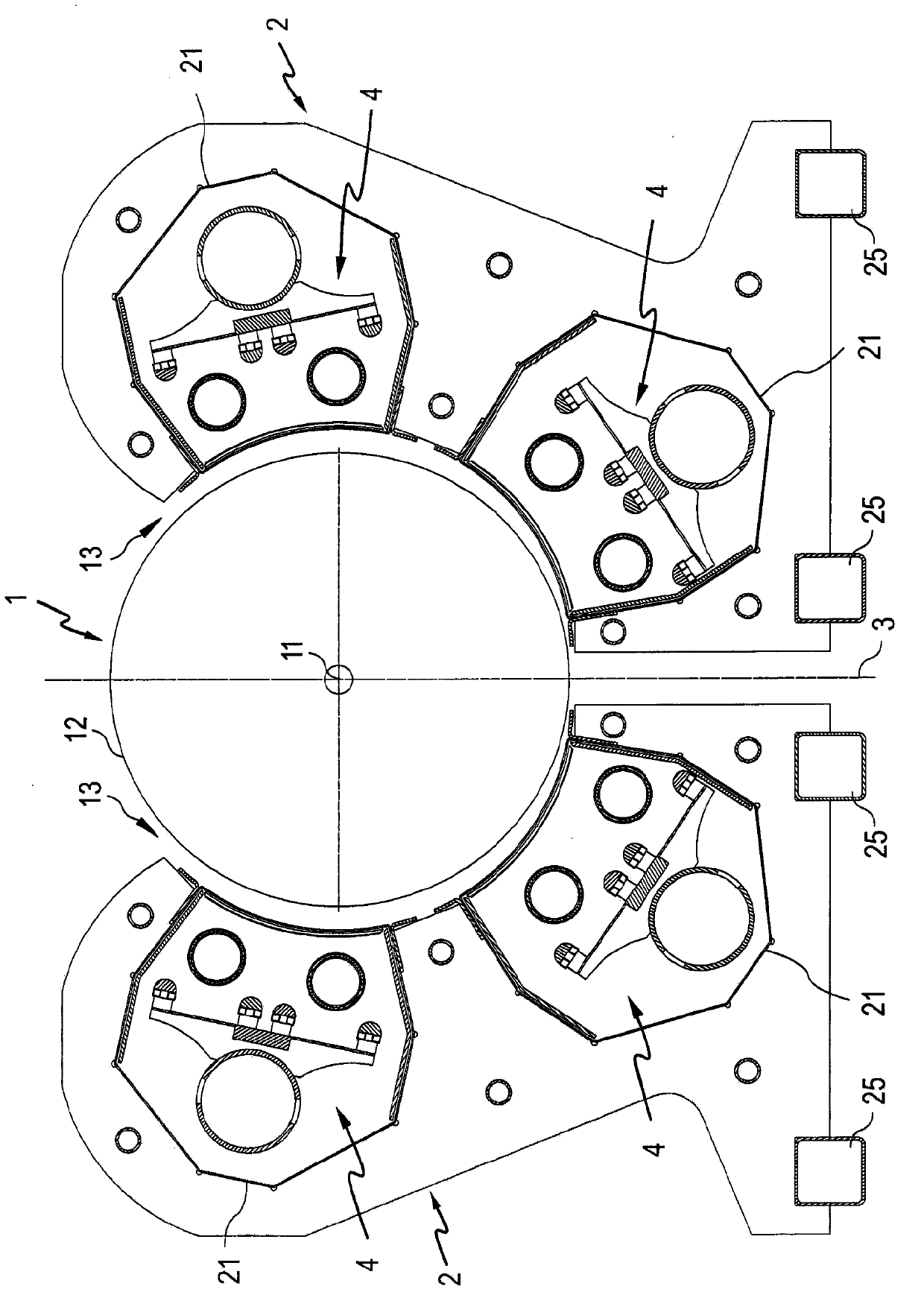

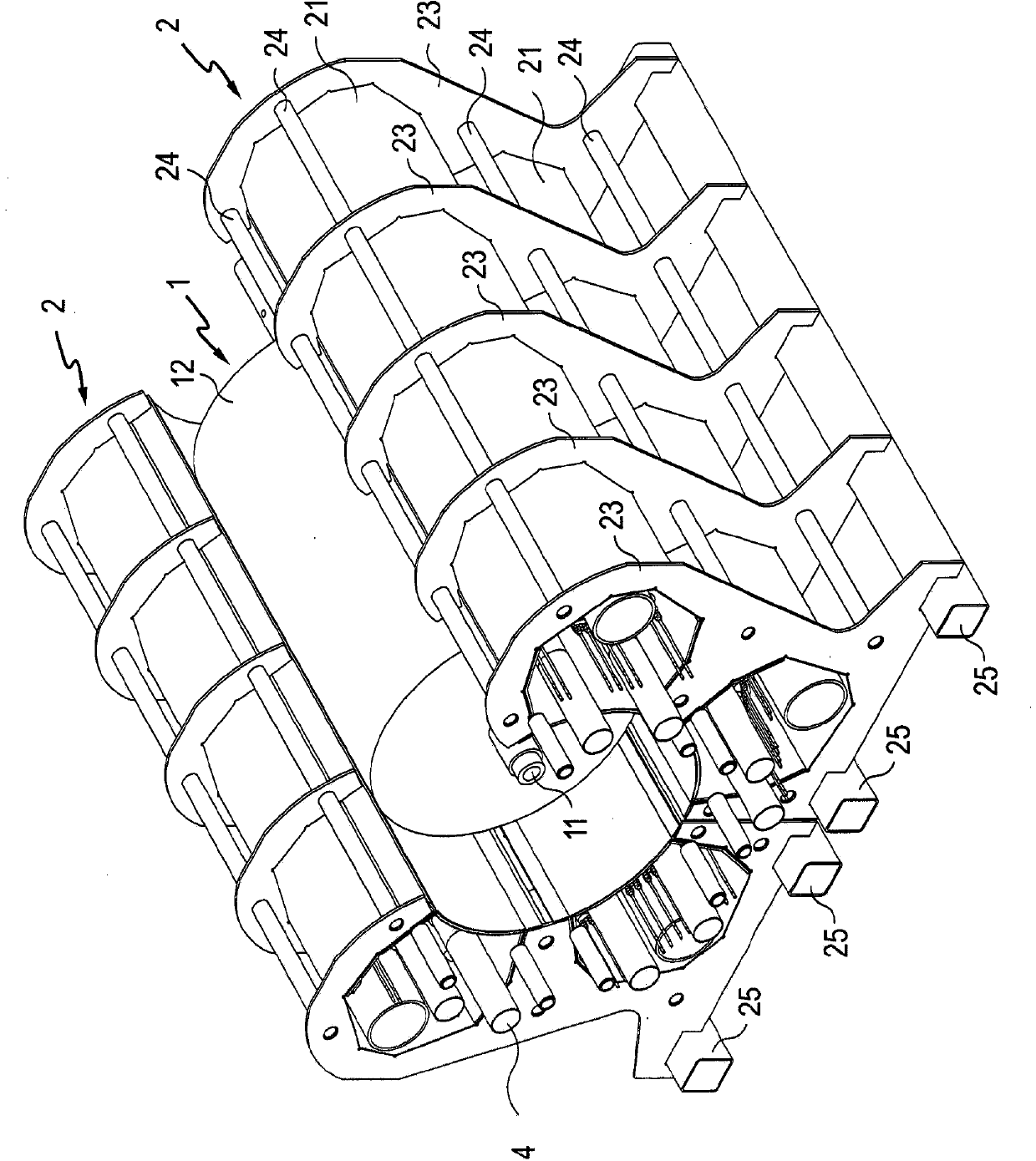

[0045] exist Figure 1 to Figure 3 The multilayer coating device shown in (not shown here) for the surface coating of strip-shaped substrates, such as plastic films, comprises a multilayer coating device with an axis of rotation 11 and for enclosing more than 180° around a peripheral side 12 The cooling roller 1 of the cylindrical peripheral side 12 of the strip-shaped substrate is guided in a partially circumferential cooling manner. For this purpose, the strip-shaped substrate is introduced from the upper left into the gap 13 between the cooling roller 1 and the arrangement of the treatment device 4 in the process chamber of the strip-shaped substrate vacuum coating system. The strip-shaped substrate passes through the gap 13 and is thus guided on the periphery of the cooling roll 1 .

[0046] The arrangement of a total of four treatment devices 4 , each configured as a sputter magnet control, with coating devices each pointing toward the peripheral side 12 , is distributed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com