Kelly bar plug valve and method

A technology of cock valve and kelly, which is applied in the direction of earth square drilling, cock including cutting device, valve details, etc. It can solve the problems of high cost, trouble, and stuck valve core to open and close the valve, and save labor in opening and closing And convenient, easy to use, reduce the effect of rotation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

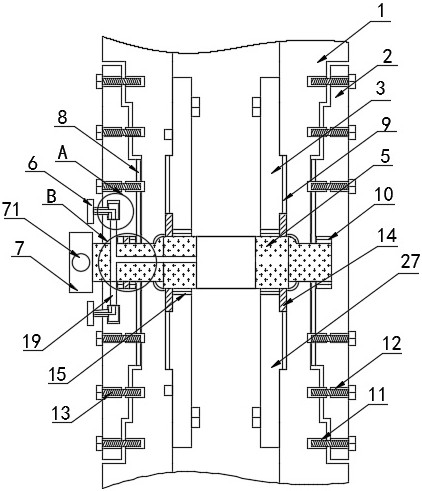

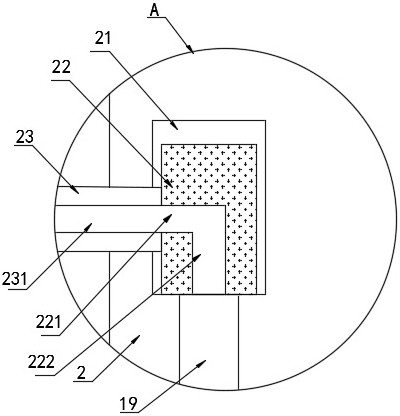

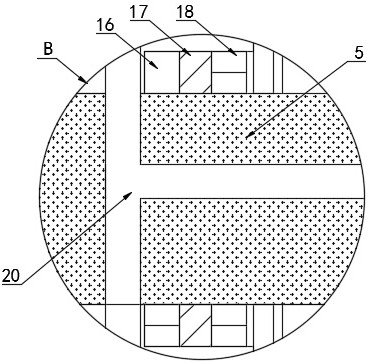

[0036] Refer to the attached Figure 1-5 , a kelly cock valve and its method in this embodiment, comprising an outer valve body 2, an inner valve body 1, an upper valve seat 3, a lower valve seat 27, a spherical valve core 5, a bearing 10 and a screw 13, the outer valve body The valve body 2 and the inner valve body 1 are provided with two groups, the outer wall of the outer valve body 2 is fixedly installed with an arc-shaped guide rod 24, the inner side of the outer valve body 2 abuts against the inner valve body 1, and the outer valve body 2 2. There is a sealing ring 1 between the inner valve body 1. The inner side of the inner valve body 1 at the upper end abuts against the upper valve seat 3, and the inner side of the inner valve body 1 at the lower end abuts against the lower valve seat 27. A sealing ring 2 is provided between the inner valve body 1, the upper valve seat 3 and the lower valve seat 27, and the right end of the spherical valve core 5 is fixedly installed ...

Embodiment 2

[0049] Refer to the attached Figure 6-7 , and the difference from Example 1 is that: the outer valve body 2 is provided with an internally threaded hole 12, and the internal valve body 1 is provided with an internally threaded hole 2 11;

[0050] The specific implementation scenarios are:

[0051] When installing, install according to the installation method on the left side of Example 1, and finally insert the U-shaped driving rod 26 on the insertion rod 71 of the switch knob 7 at the left and right ends. When opening and closing the valve, insert the U-shaped driving rod 26 26 Pull up and down to the end.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com