Electrode dust removal method

An electrode plate, dust technology, applied in chemical instruments and methods, electrostatic effect separation, solid separation and other directions, can solve problems such as affecting users, unsanitary, affecting appearance and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

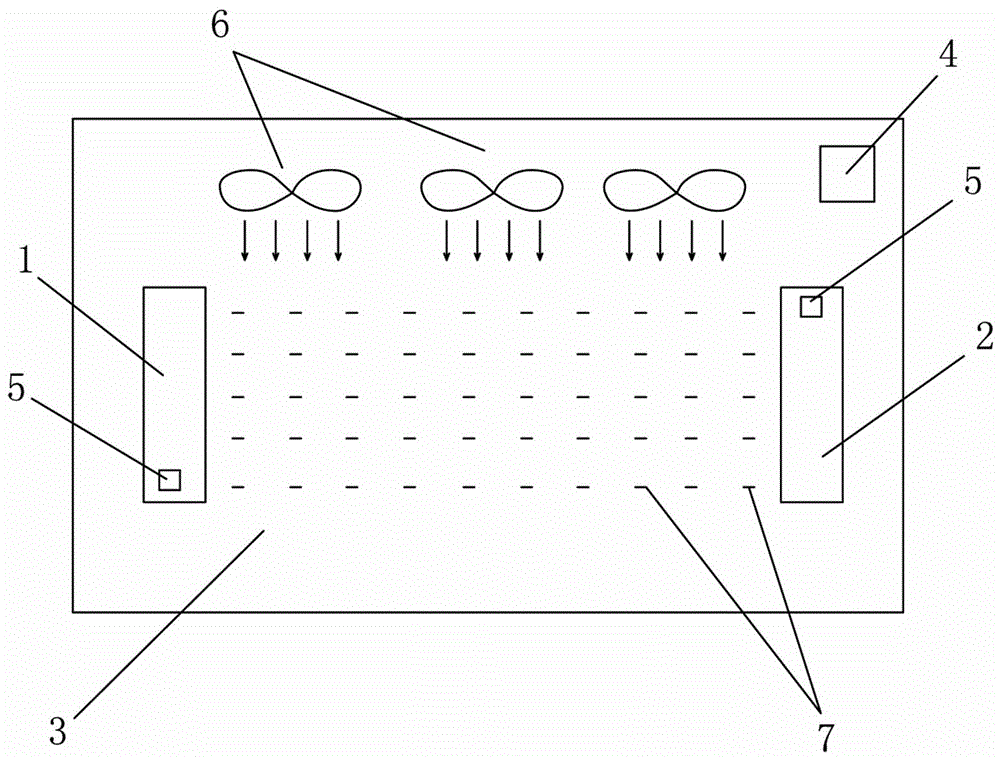

[0023] Such as figure 1 As shown, an electrode dust removal method is characterized in that it includes at least a pair of electrode plates 1 and 2 with opposite polarities, and the above electrode plates 1 and 2 are respectively installed on the positions 3 that need dust removal, and the electrode plates 1, 2 2 Apply high voltage and low current to form a high-voltage electric field between the two electrode plates 1 and 2. In order to improve the dust removal effect and increase the area of the electrode plates, the electrode plates 1 and 2 are metal electrode plates with a certain area, or electrode plates. 5 is arranged on a metal plate with a certain area to form a metal electrode plate. After electrification, the dust 7 between the two electrode plates 1 and 2 is charged, and under the force of the high-voltage electric field, the dust 7 is in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com