Winding equipment for single-warp and single-weft plain woven fabric of bamboo fibers and chemical fibers

A chemical fiber and bamboo fiber technology, which is applied in the processing of textile material equipment configuration, textile material processing, and textile material carrier processing. It can solve the problems of no coil material reinforcement extrusion, quality reduction, etc., and achieve complete drainage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

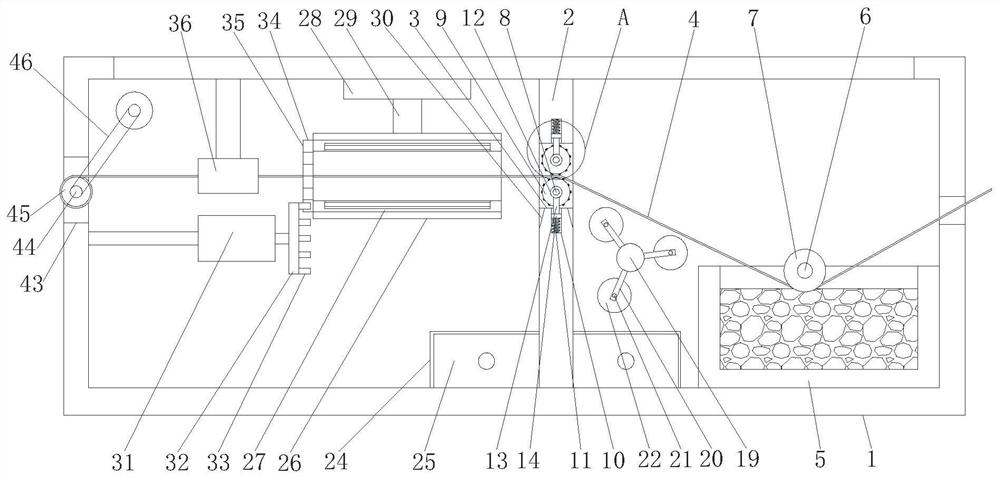

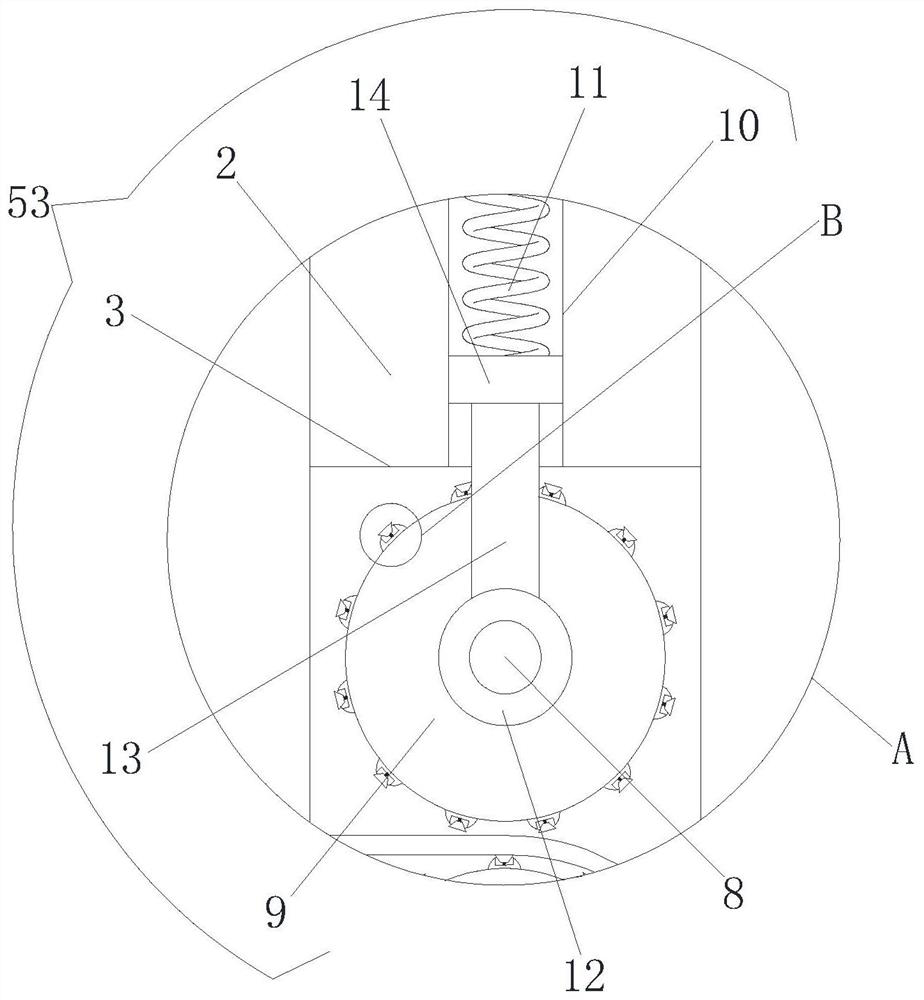

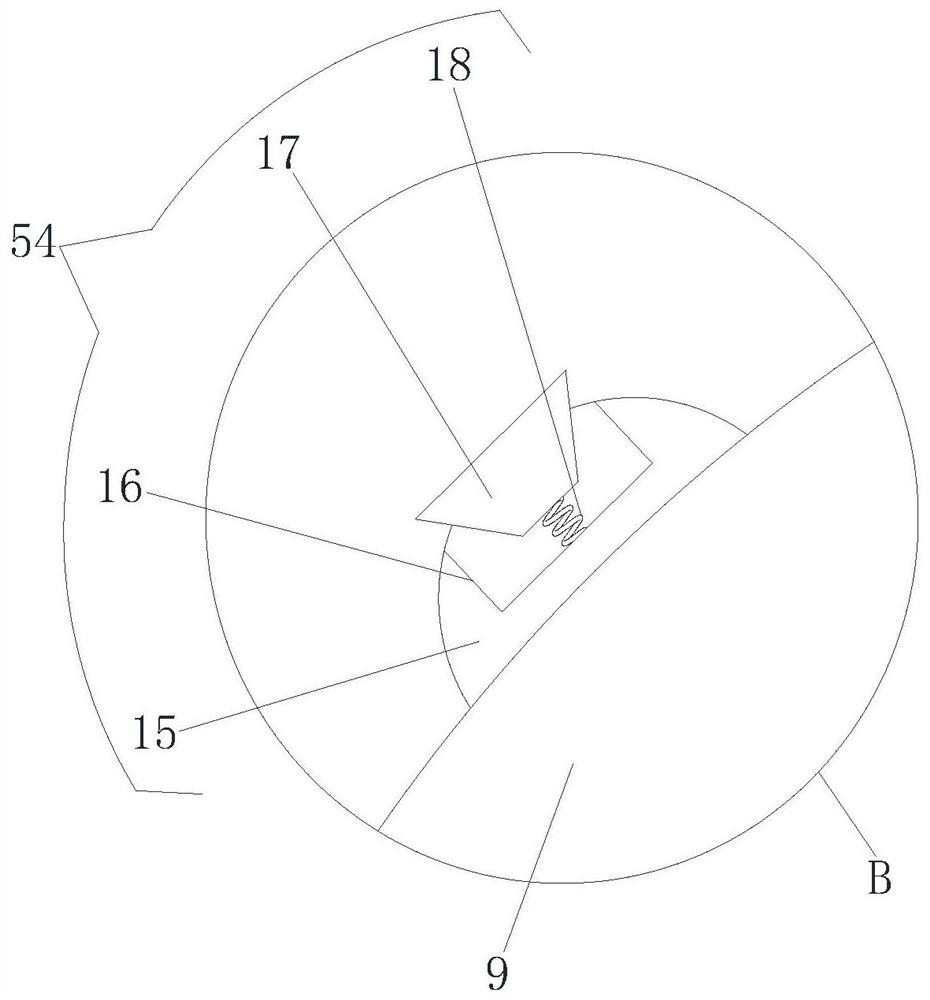

[0036] Embodiment: the winding equipment of the single warp and single weft plain weave fabric of bamboo fiber and chemical fiber, as Figure 1-Figure 11As shown, the housing 1 is included, the housing 1 is in the shape of a rectangular shell, and the inside of the housing 1 is hollow, the upper wall of the housing 1 is provided with a top groove, and the inside of the housing 1 is fixed with a partition 2, which is in the shape of a rectangular plate , the dividing plate 2 is provided with a rectangular groove 3, and the inner lower wall of the shell 1 is fixedly equipped with a dyeing pool 5, and the inside of the dyeing pool 5 is hollow, and the inside of the shell 1 is provided with a fabric 4, which is an existing structure. No need to go into details here, the inner front wall of the housing 1 is fixedly equipped with a rotating shaft 6, and the outer wall of the rotating shaft 6 is movably connected with a squeeze roller 7 through a movable bearing, and the outer wall of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com