Discharging device and tank body with same

A technology for unloading devices and tanks, which is applied to fixed-capacity gas storage tanks, container discharge methods, gas/liquid distribution and storage, etc., and can solve problems such as difficulty in liquid intake, reduced tank utilization, and economic losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In the following, the present invention will be specifically described through exemplary embodiments. It is to be understood, however, that elements, structures and characteristics described in one embodiment may be beneficially incorporated into other embodiments without further recitation.

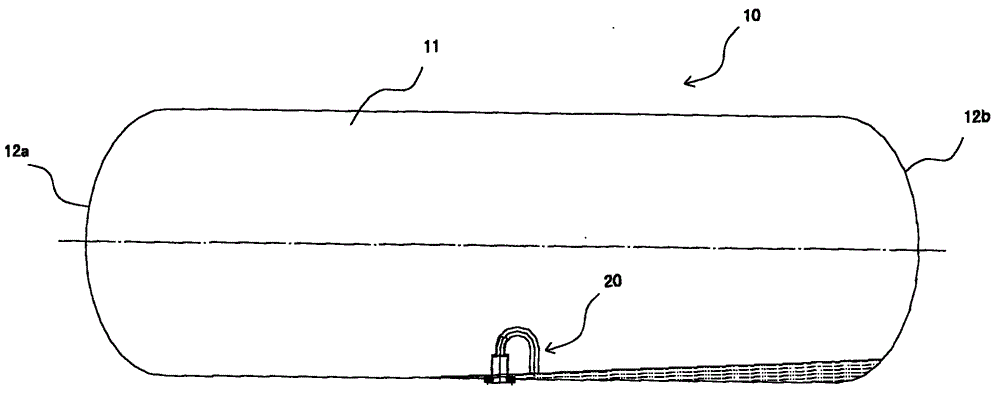

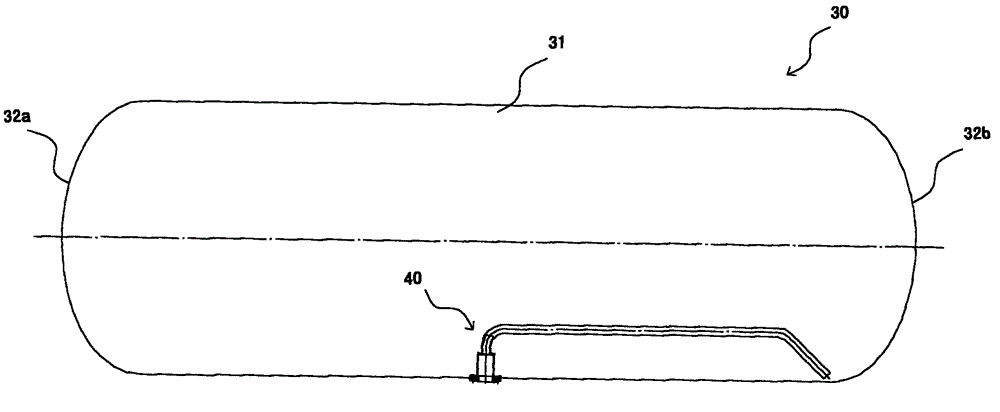

[0026] image 3 The structure of the tank body 30 according to an embodiment of the present invention is shown. The tank body 30 includes a cylinder body 31 and caps 32a, 32b provided at both ends of the cylinder body 31 .

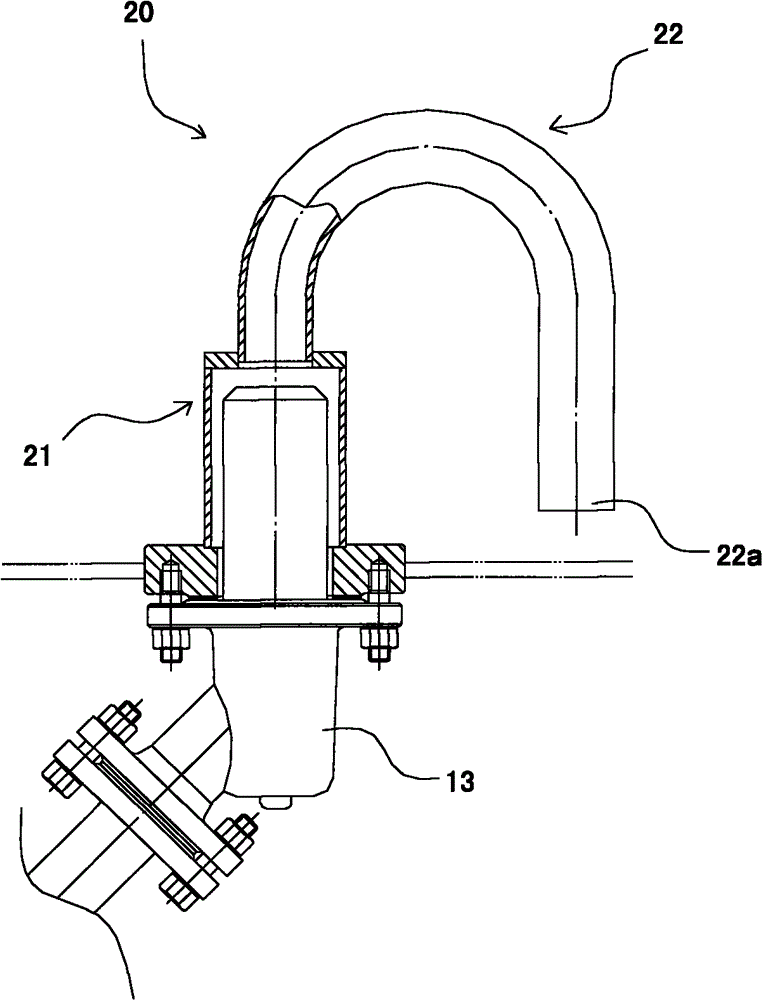

[0027] Usually, in order to facilitate the discharge of the liquefied gas inside the tank, a discharge valve 13 is also provided at the bottom of the cylinder 31 (see Figure 4 ), in order to prevent the residual moisture in the tank body 30 from freezing and blocking the discharge valve in winter, and to prevent debris in the tank body 30 from entering the discharge valve 13, thereby affecting the normal discharge of the tank body, the tank body 30 is also ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com