Oil well pump capable of automatically draining oil

An oil well pump and self-draining technology, which is applied in the field of self-draining oil well pumps, can solve problems such as splashing, difficult operation, and unfavorable safety, and achieve the effects of preventing environmental pollution, avoiding external splashing, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

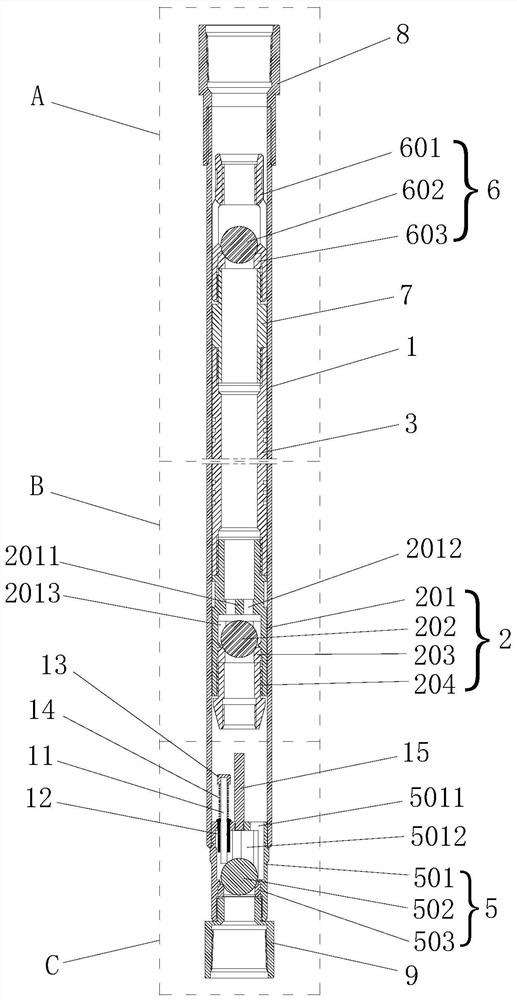

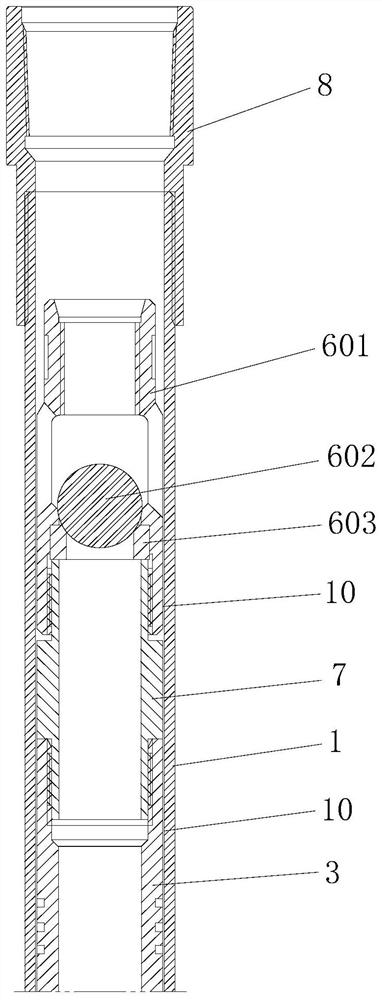

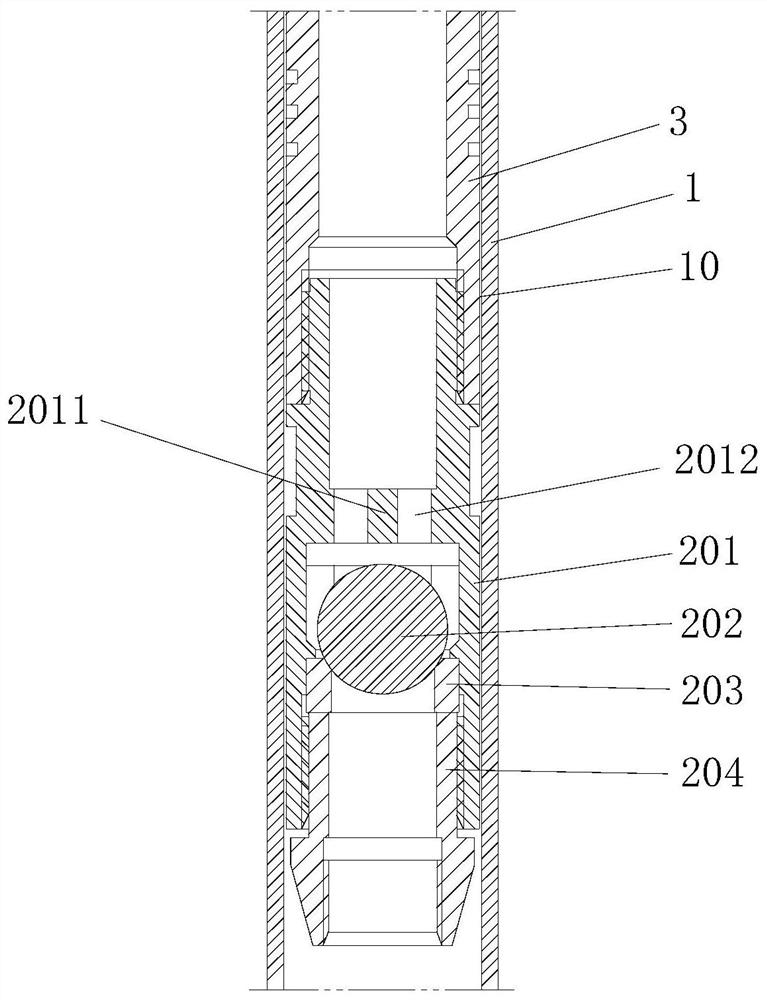

[0056] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, specific embodiments of the present invention will now be described with reference to the accompanying drawings.

[0057] like Figure 1 to Figure 6 As shown, the present invention provides a self-draining oil well pump, which is arranged at the bottom of the sucker rod and goes down to a preset position in the wellbore with the sucker rod. The self-draining oil pump includes a pump barrel 1 and a plunger 3. Both the pump barrel 1 and the plunger 3 are cylindrical structures arranged in a vertical direction with openings at both ends, and the plunger 3 can slide up and down (ie : arranged in the interior of the pump barrel 1 along the axial direction of the pump barrel 1, the top of the plunger 3 is connected with the lowering pipe string, the bottom of the plunger 3 is provided with the first ball valve 2 with upward one-way conduction, Inside the first b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com