Detection and grading device of pxe piston grading machine

A piston and classification technology, which is applied in the field of detection and classification devices, can solve the problems affecting the defective rate of pistons, low classification efficiency, piston collision, etc., and achieve the effects of convenient automatic measurement, improved efficiency and high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

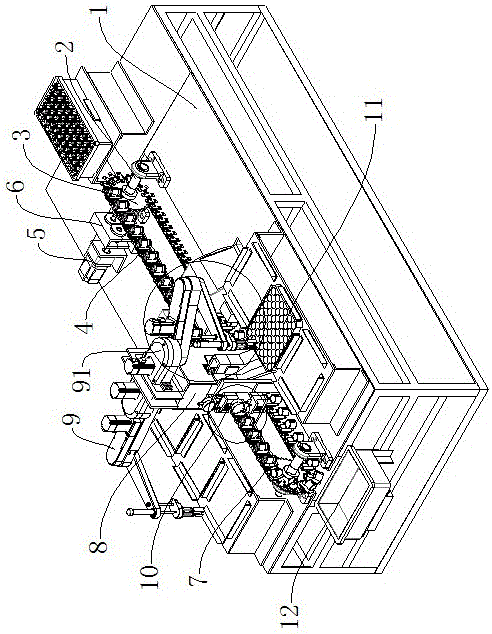

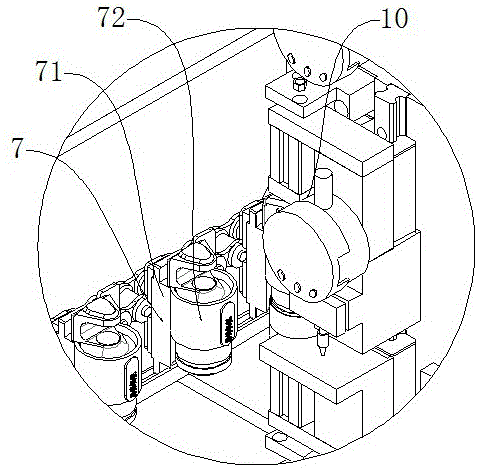

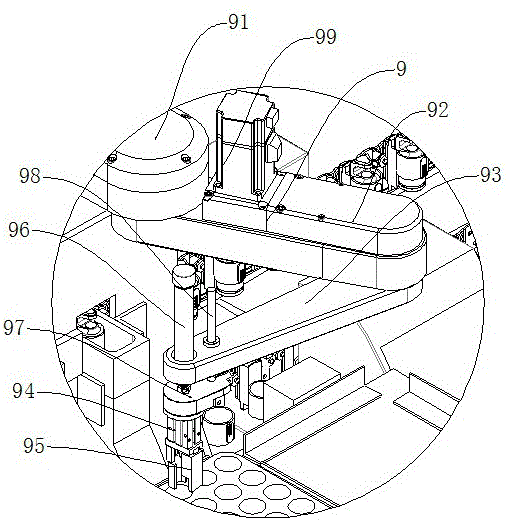

[0019] Such as figure 1 , shown, the detecting and classifying device of the PXE piston classifying machine described in the present embodiment, it comprises frame 1, is provided with rotating shaft 2 transversely at both ends of frame 1, is provided with sprocket 3 on rotating shaft 2, in A chain 4 is wound around the two sprockets 3, and the chain 4 is in a vertical plane. One of the rotating shafts 2 is connected to the No. 1 motor 5 through a gearbox 6, and piston tooling 7 is evenly spaced on the chain 4. The middle position of the frame 1 on one side of 4 is provided with a column 8, and a piston automatic measuring instrument 10 is provided on the column 8 corresponding to the chain 4 of the upper half to measure the piston, and a manipulator is provided at the upper end of the column 8 9. An air gripper 94 is provided on the top of the manipulator 9, and two clamping blocks 95 are arranged on the air gripper 94, and a material tray 11 is arranged on the frame 1 below t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com