Automatic screwdriver

A screwdriver, automatic technology, used in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of high labor costs, inability to apply fully automatic production, poor efficiency, etc., and achieve low labor costs, low cost, and high efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

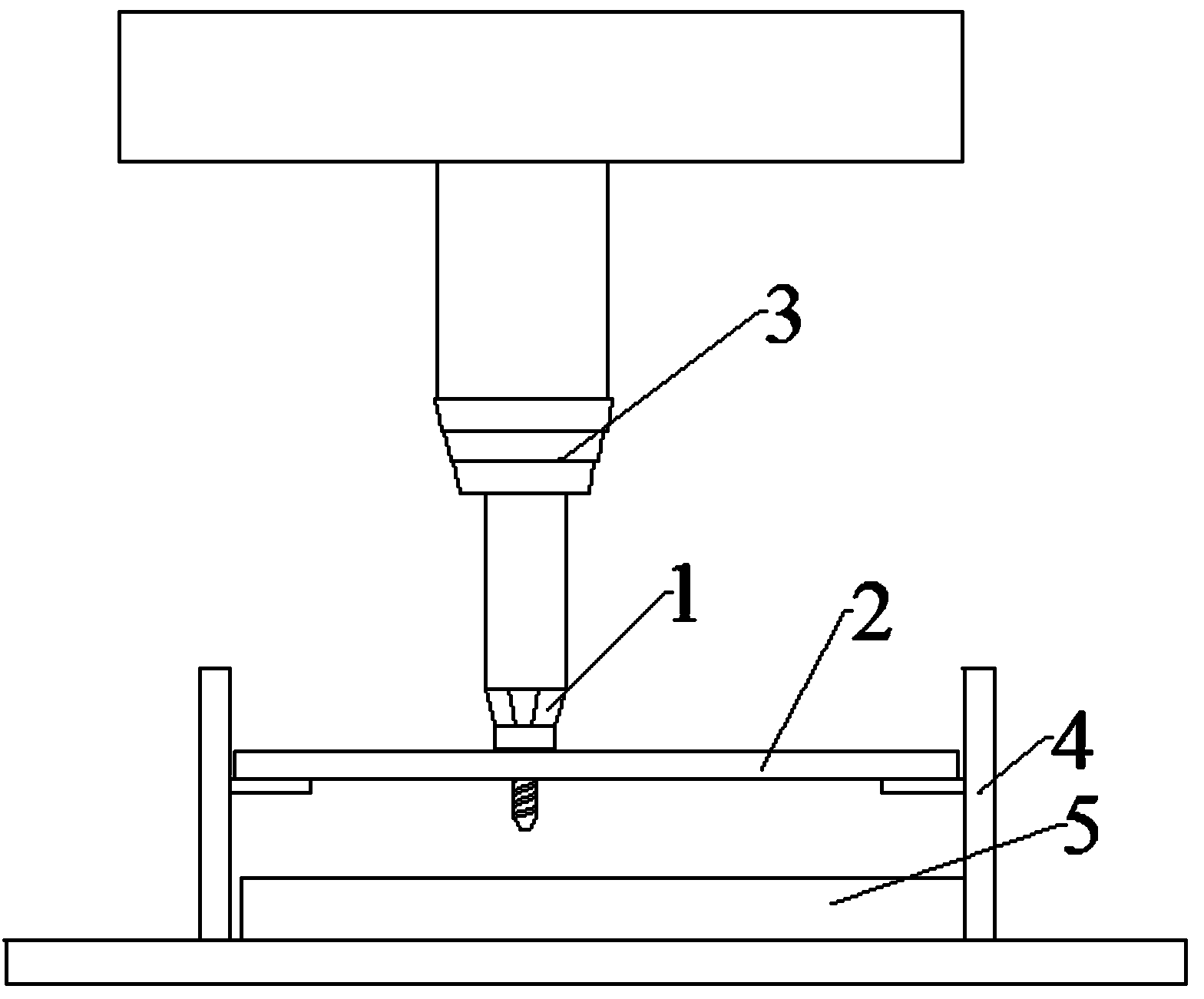

[0018] The automatic screwdriver 1 includes: a placement plate 2 fixed on the product 5 to be screwed and used for placing nails, a screwdriver 1 that can automatically rotate and align with the nails, and a telescopic rod 3 fixed on the screwdriver 1 .

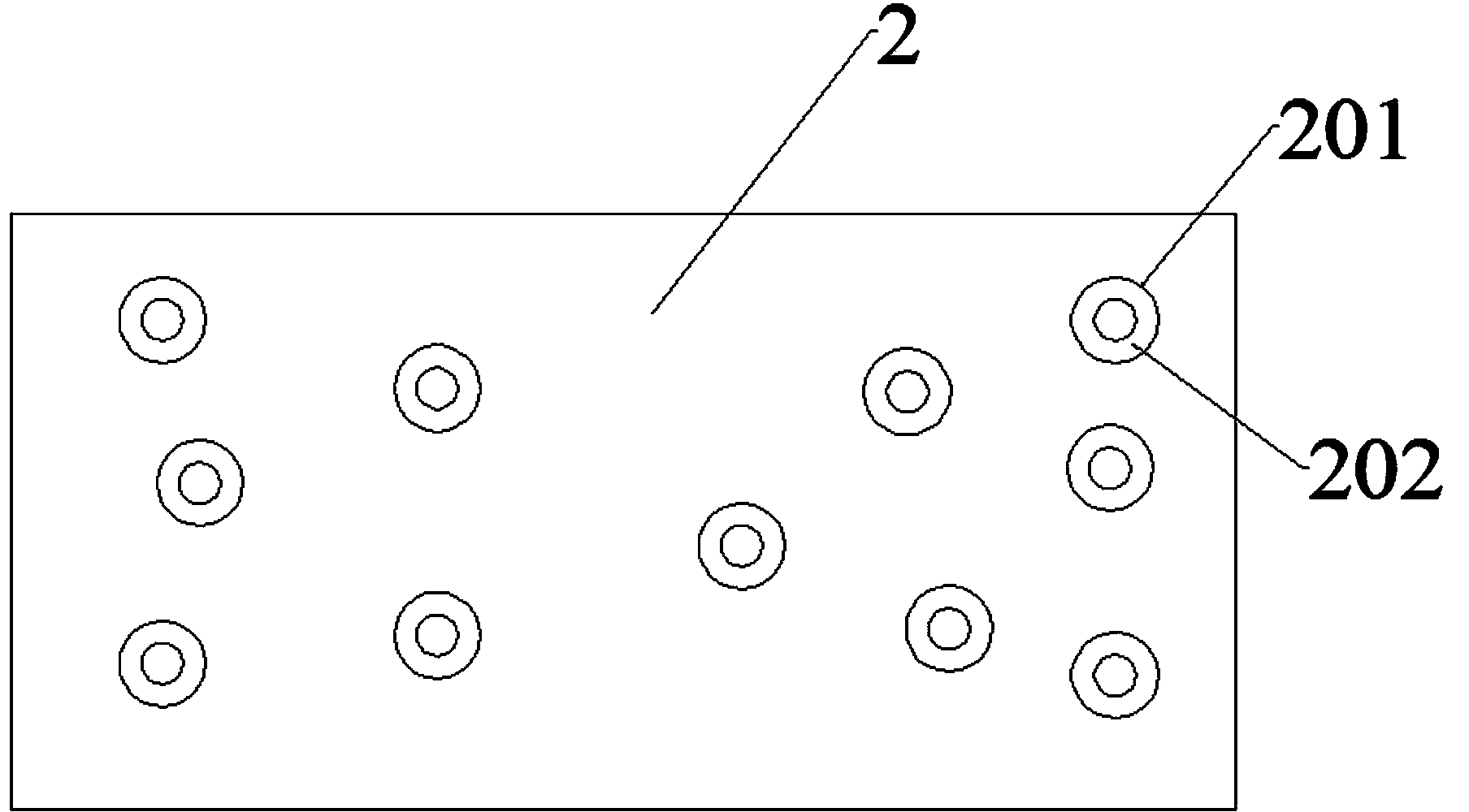

[0019] The placement plate 2 is provided with a limit assembly corresponding to the position where the screw needs to be installed on the product 5 and used to limit the nail; the limit assembly consists of: a placement plate 201 corresponding to the position of the installation screw, and an elastic ring 202 placed on the inner ring of the placement plate 201 ; As a preference, the elastic ring 202 is a rubber ring.

[0020] In order to facilitate the smooth passage of the bolt ends, the diameter of the placing plate 201 is greater than or equal to the diameter of the screw, and the dia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com