Anti-drop wear-resisting novel thin film paper tube

A film paper tube and anti-dropping technology, which is applied in the field of paper tube manufacturing, can solve the problems of ambiguity, waste of resources and efficiency, and high processing cost, and achieve the effects of reducing the probability of fire, reducing losses and improving production quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

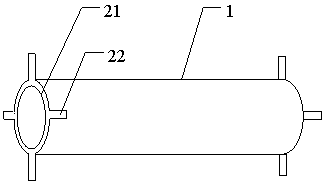

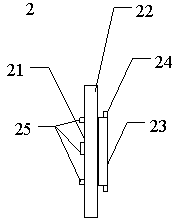

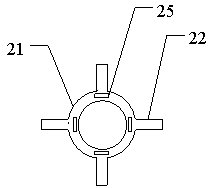

[0023] see figure 1 , 2 , 3, 5, this embodiment provides a new type of anti-off and wear-resistant film paper tube, including a cylindrical paper tube body 1 and an anti-off part 2. The two ends of the body 1 are not closed; the two ends of the body 1 are provided with anti-off parts 2, and the anti-off parts 2 include a ring frame 21 and at least two baffles 22, preferably four in this embodiment. The ring frame 21 and the baffle plate 22 of the anti-off component 2 are integrally formed, and the four baffle plates 22 are evenly distributed along the circumference of the ring frame.

[0024] The anti-loosening component 2 is provided with an annular locking position 23 on the side in contact with the main body 1, and at least two protrusions 24 are arranged on the side of the annular locking position 23 in contact with the inner side of the main body 1, and the protrusions are movable structures. In this embodiment, there are preferably four protrusions 24, which are consis...

Embodiment 2

[0030] As a preferred version of the present invention, see Figure 4 , the outside of the paper tube substrate layer 11 is coated with a first fireproof coating 12 and a second fireproof coating 13 . The first fireproof coating 12 is nitrogen-containing resin, perchlorethylene resin or vinyl chloride copolymer resin, which can release non-combustible gas or fire extinguishing gas when burning in case of fire; the second fireproof coating 13 is phosphorus nitrogen system Flame retardant, when exposed to heat, it produces an endothermic effect, forms a non-volatile covering layer, and blocks the combustion chain. Because the fireproof layer is coated on the outer side of the base layer of the paper tube, the probability of fire is effectively reduced and the loss is reduced.

[0031] Others are the same as embodiment one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com