Two-direction mechanical locking hydraulic cylinder

A technology of hydraulic cylinders and mechanical locks, applied in the field of hydraulic cylinders, can solve the problems of high requirements on machining accuracy of piston rod sleeves, difficult to ensure self-locking reliability, and inability to meet high-precision locking and other problems, so as to achieve broad prospects for promotion and use. Avoid the effect of being unable to unlock and lock reliably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below with reference to the accompanying drawings and examples.

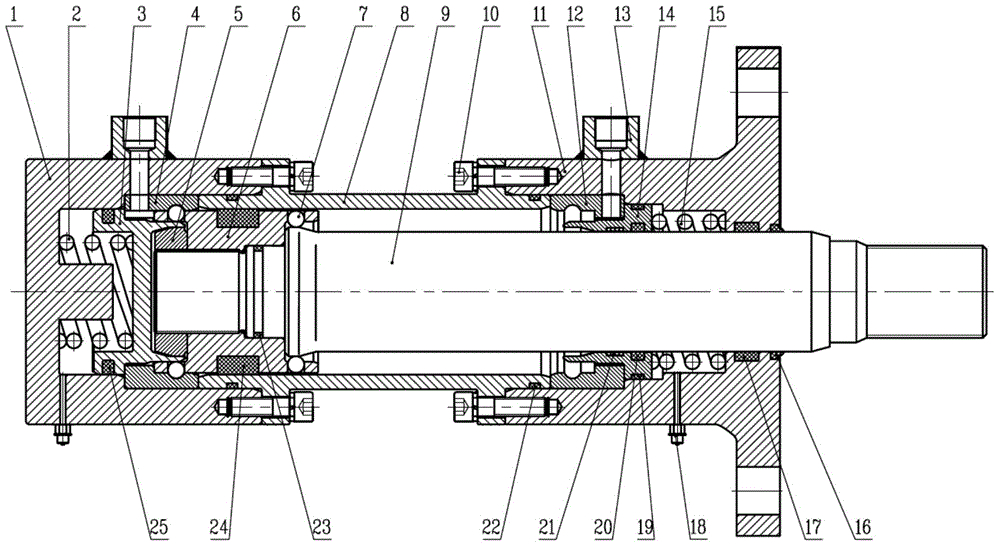

[0030] as attached figure 1 As shown, the two-way mechanical locking hydraulic cylinder of the present invention includes a cylinder bottom 1, a rear spring 2, a rear spring seat 3, a rear locking seat 4, a lock nut 5, a piston 6, a steel ball 7, a cylinder barrel 8, a piston rod 9. Bolt 10, cylinder head 11, front locking seat 12, oil port 13, front spring seat 14, front spring 15, dustproof ring 16, cylinder head sealing ring 17, oil drain port 18, front spring seat shaft sealing ring 19. Front spring seat hole seal ring 20, front spring seat support ring 21, cylinder barrel seal ring 22, inner seal ring 23, piston seal ring 24 and rear spring seat seal ring 25.

[0031] One end of the cylinder bottom 1 is provided with a coaxial annular groove and a spring guide post, and the outer peripheral surface of the cylinder bottom 1 is provided with a cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com