Bearing axial play measuring method

A measurement method and technology of axial clearance, applied in the direction of mechanical clearance measurement, etc., can solve problems such as difficult quantification, inaccurate measurement results, difficulty in ensuring consistent thrust or pulling force, etc., to achieve consistent size and bearing axial clearance value-accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

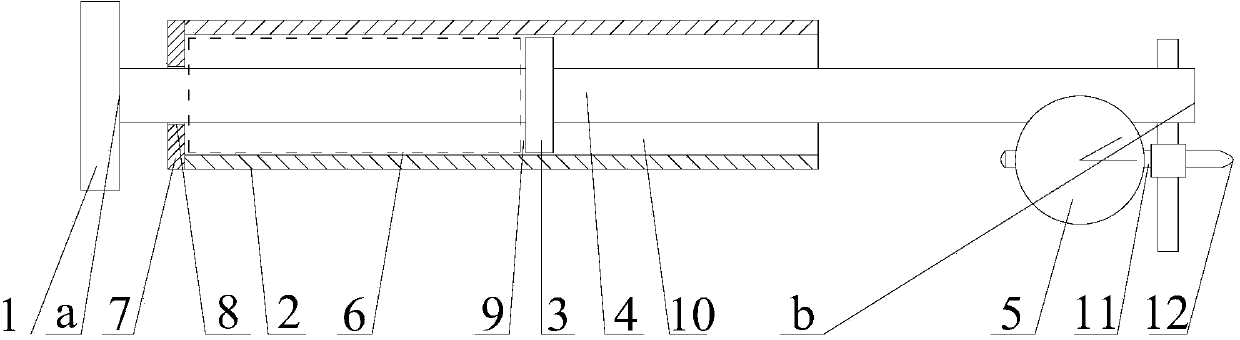

[0049] See attached figure 1 , The bearing axial clearance measuring device provided by Embodiment 1 of the present invention includes a head 1 , a sleeve 2 , a slider 3 , a connecting rod 4 , a dial gauge 5 and a force applying unit 6 . The sleeve 2 includes a side wall and a first end cover 7, the first end cover 7 is arranged on one end of the side wall, the first end cover 7 is provided with a first through hole 8, and the end 1 is fixedly connected to the connecting rod 4 One end a, the end head 1 is located outside the first end cover 7 , the connecting rod 4 passes through the first through hole 8 and forms a first sliding pair with the first end cover 7 . The slider 3 is fixedly connected to the connecting rod 4. The slider 3 is arranged in the sleeve 2 and forms a second sliding pair with the inner wall of the sleeve 2. The slider 3 divides the inner cavity of the sleeve into the first accommodation space. 9 and the second accommodating space 10, the first accommodat...

Embodiment 2

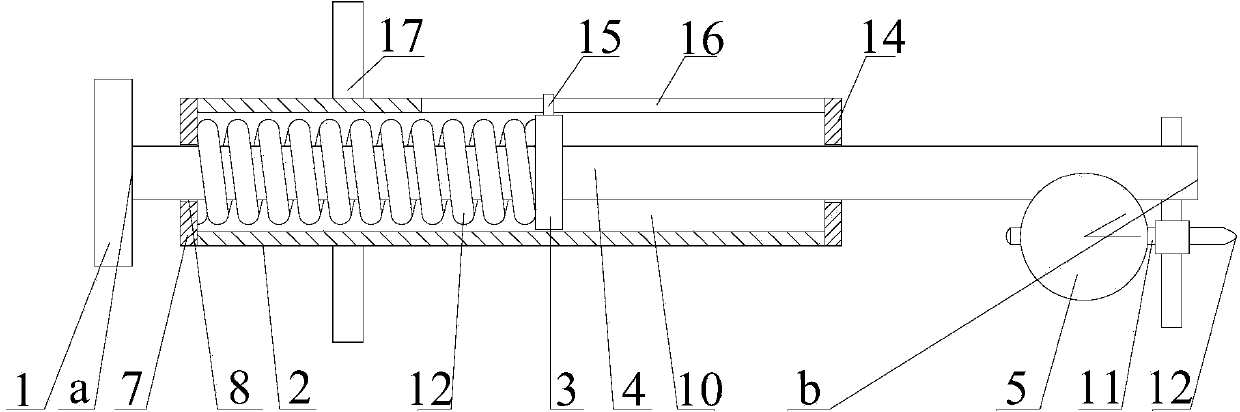

[0052] See attached figure 2 The difference between the bearing axial clearance measuring device provided in Embodiment 2 of the present invention and the bearing axial clearance measuring device provided in Embodiment 1 of the present invention is that the bearing axial clearance measuring device provided in Embodiment 2 of the present invention The force applying unit 6 includes an elastic member 12, which is sleeved on the connecting rod 4, one end of the elastic member 12 is fixedly connected to the first end cover 7, and the other end of the elastic member 12 is fixedly connected to the slider 3, usually Below, the elastic member 12 is in a natural state.

[0053] In this embodiment, the elastic member 12 is a spring. Under the conditions of this embodiment, it is only necessary to compress the spring to the limit position each time a force is applied. According to Hooke's law, the compression amount of the same spring is proportional to the magnitude of the applied force...

Embodiment 3

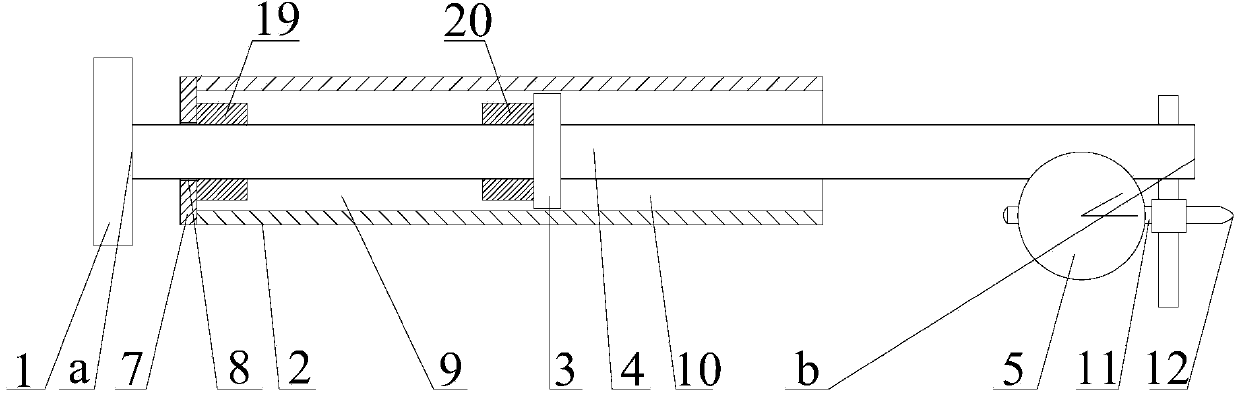

[0060] See attached image 3 The difference between the bearing axial clearance measuring device provided in the third embodiment of the present invention and the bearing axial clearance measuring device provided in the first embodiment of the present invention is that the implementation of the bearing axial clearance measuring device provided in the third embodiment of the present invention The force unit includes a first magnet 19 and a second magnet 20, the first magnet 19 is fixedly connected to the first end cover 7, the second magnet 20 is fixedly connected to the slider 3, the magnetic properties of the first magnet 19 and the second magnet 20 are the same, Normally, there is no magnetic force between the first magnet 19 and the second magnet 20 .

[0061] When applied, with the attached Figure 6 ~ attached Figure 7 Similarly, the end 1 is stuck on the outer ring of the bearing 24, the measuring head 12 of the dial indicator 5 is against the outside of the hub hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com