Method for determining the influence of impurities on the thermal stability of solid self-reactive substances

A technology of thermal stability and self-reaction, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems that the test method of thermal stability of solid self-reactive substances has not yet been established.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

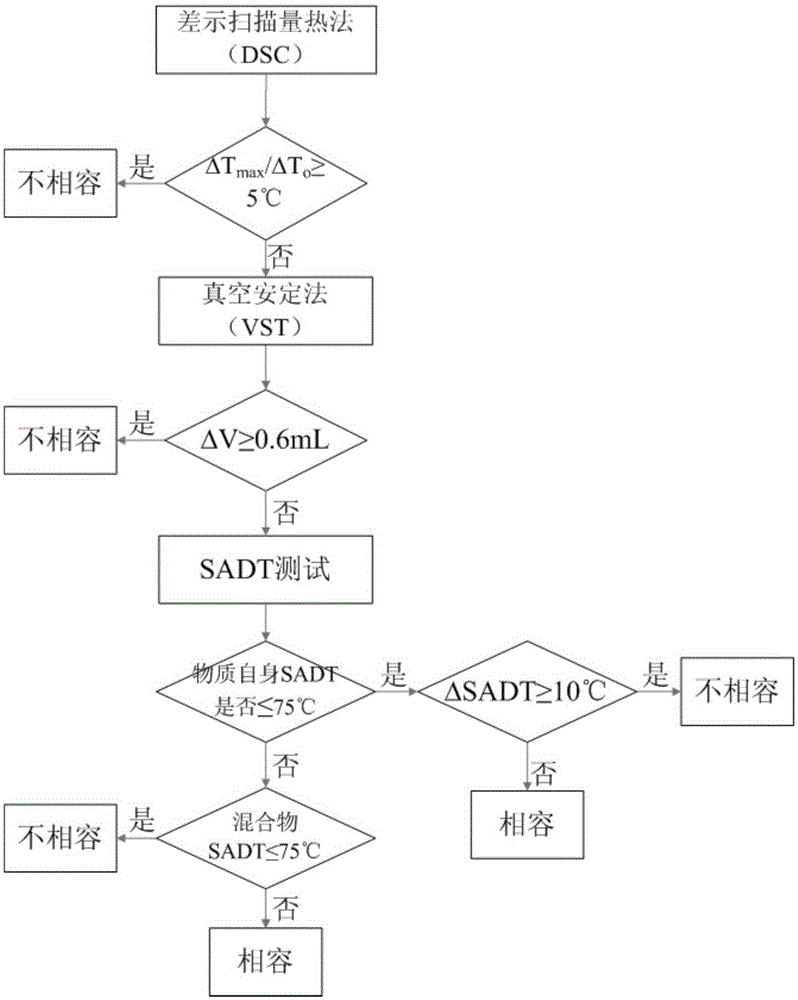

Image

Examples

Embodiment 1

[0015] The specific steps of differential scanning calorimetry test, vacuum stability test and self-accelerating decomposition temperature (SADT) test involved in the present invention are as follows:

[0016] 1. Differential scanning calorimetry test

[0017] 1. Principle

[0018] The measured solid self-reactive substance and the mixture of the measured solid self-reactive substance and impurities are at different temperatures. Due to chemical or physical changes, thermal effects can cause changes in the temperature of the measured substance. Use a differential scanning calorimeter to measure and record the relationship between the temperature difference between the measured substance and the reference substance and the temperature, and draw a curve (that is, the DSC curve). By calculating the magnitude of the variable on the curve relative to the initial exothermic temperature or peak temperature of the mixed system on the curve relative to the individual system as a refer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com