Optical antireflection film adopting two coating materials

A technology of optical anti-reflection coating and film layer, which is applied in the direction of coating, etc., can solve the problems that are difficult to meet, the optical performance limitation of optical components, and the narrow light transmission band, so as to improve the imaging quality, ensure the green appearance, and increase the luminous flux. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described below in conjunction with specific embodiments.

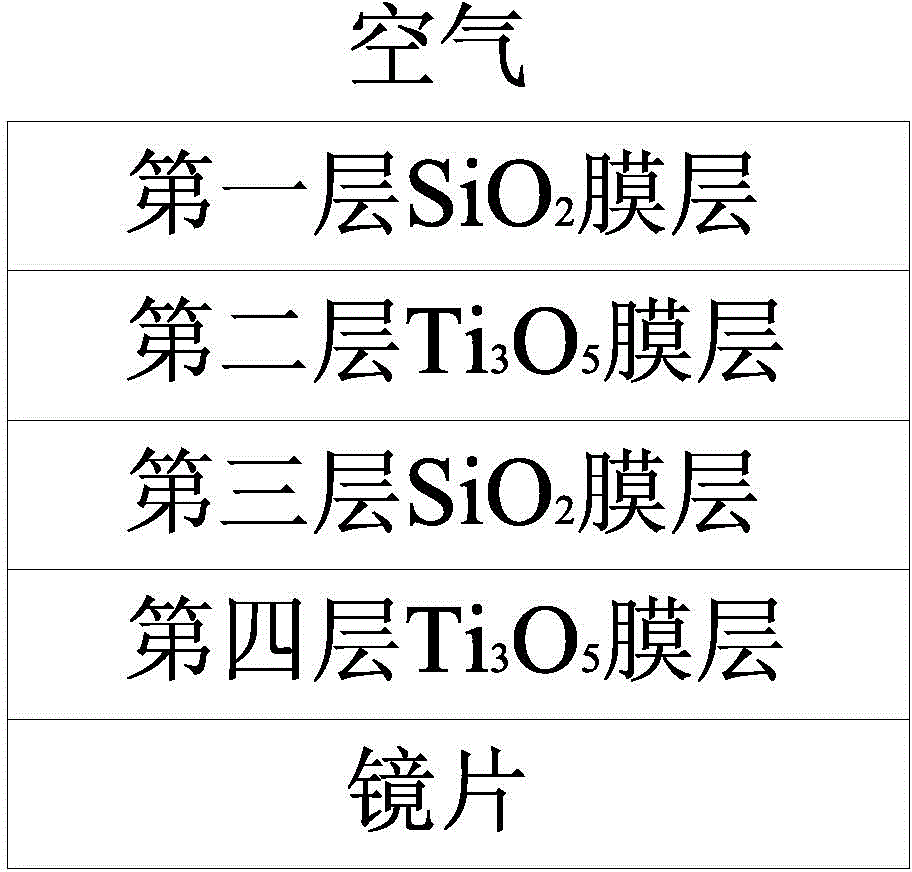

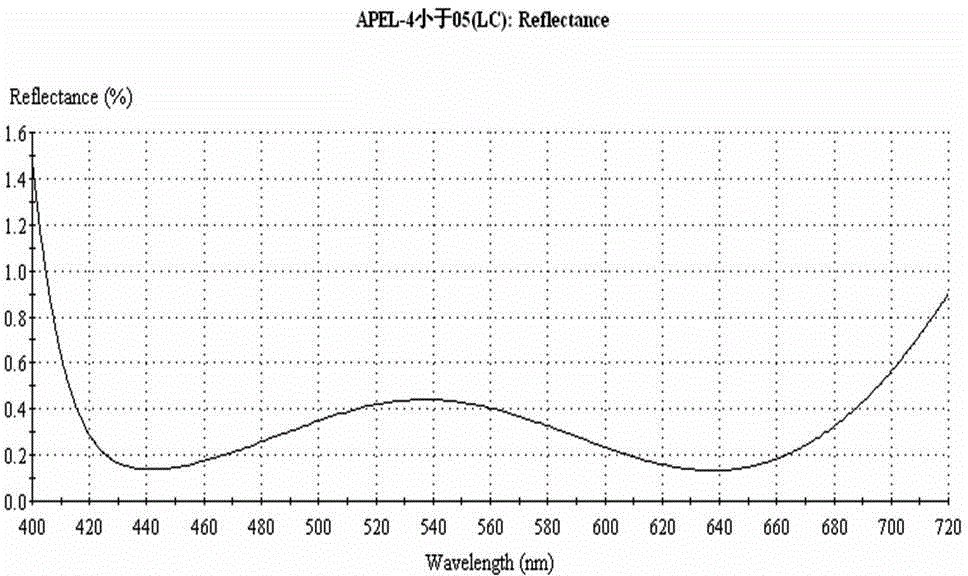

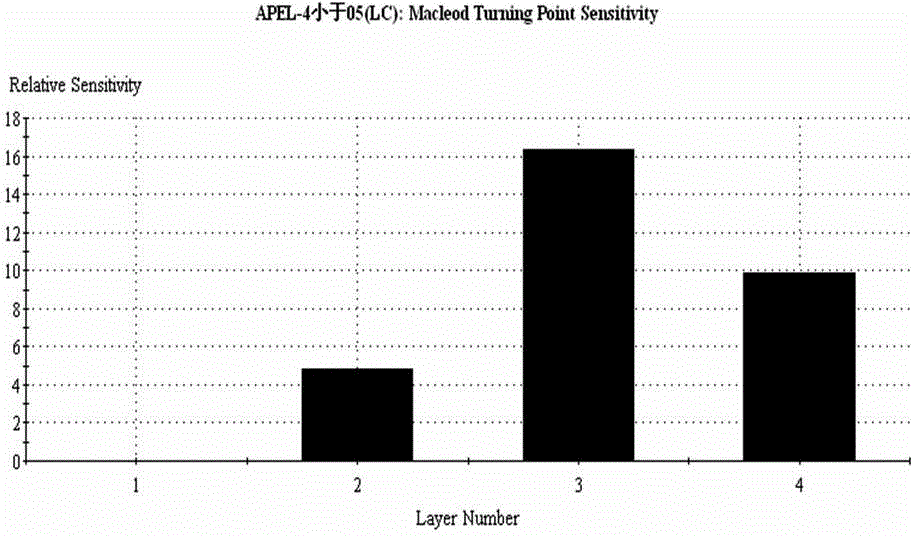

[0020] Such as Figure 1 to Figure 3 As shown, an optical anti-reflection coating using two kinds of coating materials, including the lens, the lens is coated with four layers of coating, the coating formula is: G|HLHL|A; where G is the lens, A is air, two vertical lines It has no practical significance, and the vertical lines represent the coating layer; H is Ti 3 o 5 , L is SiO 2 ; that is, the four-layer film layer is the first layer of SiO from top to bottom 2 Film layer, second layer Ti 3 o 5 Film layer, the third layer of SiO 2 Film layer, the fourth layer Ti 3 o 5 film layer, the first layer of SiO 2 The film layer is the surface film in contact with the air, the fourth layer Ti 3 o 5 The film layer is the lens film layer close to the lens;

[0021] The total physical thickness of the four layers is 256.69nm;

[0022] The thickness of each layer is:

[0023] Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| angle of incidence | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com